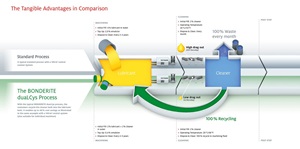

Henkel introduces new Bonderite duaLCys process for the metalworking industry. Bonderite duaLCys process exploits lubricant-cleaner synergies to reduce costs, boost performance, save energy, lower waste generation, and improve working conditions.

In the Bonderite duaLCys process, the cleaning fluid is recycled into the lubricant bath, rather than being discarded as waste.

Martin Desinger, business development manager, Lubricants, Europe, at Henkel Adhesive Technologies said: “Recycling the cleaning fluid instead of throwing it away, and making use of synergies between it and the water-soluble cutting fluid, results in an excellent combination of high lubricity, superior part cleanliness and excellent corrosion protection.”

This new process is the synergy between a lubricant and a cleaner: Bonderite C-NE 10466 high-performance, water-based neutral cleaner, and Bonderite L-MR 21466 cutting fluid. The cleaner produces no foam in hard water, provides excellent corrosion protection and can be used at room temperature. The machining fluid is a finely dispersed lubricant. Both are boron- and bactericide-free. The resultant bacteride-free lubricant also features pre-cleaning properties due to its combined formulation. Desinger notes: “Operations can save up to 40% process-costs, and can reduce lubricant drag-out by as much as 70%.”