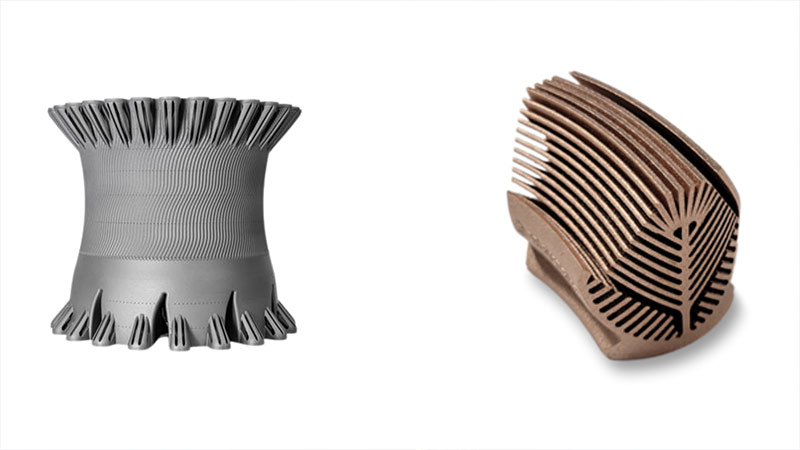

3D Systems announced the addition of two new materials Certified HX and Certified CuCr2.4 to its materials portfolio. Both materials are certified for use with the company’s DMP Flex 350, and DMP Factory 350 3D printers, and HX is also certified for the DMP Factory 500. Certified HX is a high-performance nickel alloy that contains a higher percentage of molybdenum (up to 9.5%) versus other nickel alloys which enhances its strength and resistance to corrosion, creep deformation, cracking, and oxidation in hot zone environments. Certified HX is ideal for producing tall, large parts with integrated cooling and flow channels in optimal orientation for the energy, industrial gas turbine (IGT), petro-chemical, and aerospace & defense industries.

Certified CuCr2.4 is a high-strength, corrosion-resistant copper alloy that is significantly stronger than pure copper and easier to process for additive manufacturing applications. Its superior part density (typically 99.9%) and high conductivity after heat treatment make CuCr2.4 ideal for heat management and cooling systems in the high-tech, consumer goods, automotive, and aerospace & defense industries, especially when strength is also a requirement.