3DEO has announced the launch of 316L austenitic stainless steel. The new material is available to customers across all industries, especially in medical, industrial, marine and food processing.

Text and images by 3DEO

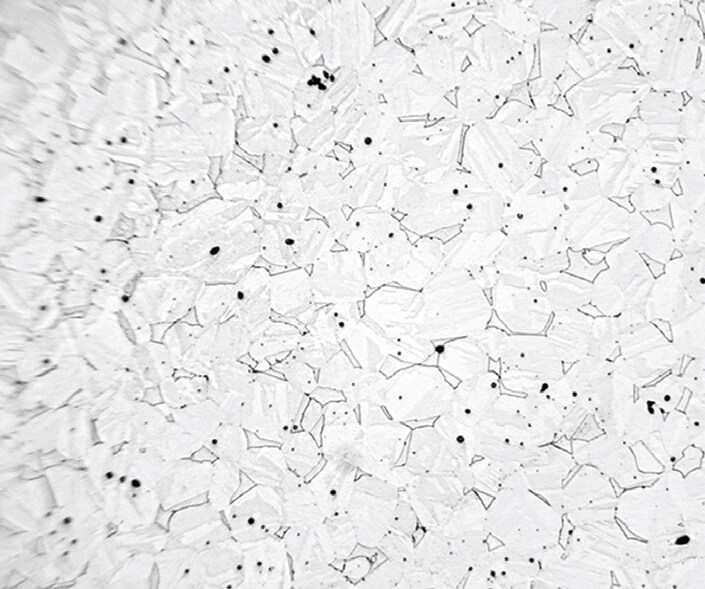

A fully austenitic, non-magnetic stainless steel, 316L (equivalent to UNS S31603) maintains excellent performance at room and moderately elevated temperatures, as well as excellent ductility and mechanical performance. This weldable material is extremely corrosion resistant, which makes it ideal for applications that will experience harsh environments.

“Our talented team of material scientists have been hard at work testing and validating 316L on our technology, and we are thrilled with the results,” said Matt Petros, CEO and co-founder of 3DEO. “With material properties that meet the MPIF Standard 35 standards, introducing 316L to our customers

will allow them to take advantage of the benefits, time-savings and cost-efficiencies of 3D-printing using a biocompatible, corrosion-resistant material like 316L for their high-demand applications.”

316L stainless steel

316L is commonly used in applications such as laboratory equipment, impellers and pumps, engine parts, food processing equipment, jewelry, kitchen appliances, surgical instruments, marine, chemical and petrochemical processing, and more.

“As our customers aim to innovate and gain a competitive edge with their next generation and new-to-market products, we have seen strong demand for 316L,” continued Petros.

“Introducing this to our customers will continue to enable engineers to develop premium products for a wide variety of demanding applications in partnership with 3DEO.”

3DEO helps customers with their complex metal components at every stage of the product life cycle, from early ideation and prototyping to manufacturing at scale. And because prototypes are manufactured using the same machines and technologies as longer production runs, with 3DEO, customers can seamlessly progress from prototype to production without the need to undergo lengthy or costly design changes or requalifications to launch products.

“We love to help our customers do what hasn’t been done before and solve their toughest problems,” said CTO Payman Torabi. “We partner on the design and prototyping to prove novel designs. Then, after the necessary product testing is complete, 3DEO can get them into production faster than any other metal production technology.”

17-4PH stainless steel

3DEO also offers 3D-printing in 17-4PH stainless steel, which is an alloy widely used for applications requiring high strength in mildly corrosive environments. With near wrought part density in excess of 99%, excellent mechanical properties up to ~316 °C, and the best surface finish in metal AM, 3DEO’s 17-4PH 3D-printed components enable customers to get to market fast with innovative designs and a high performing end-use product.

Powders

3DEO’s proprietary powder is formulated for their patented metal 3D-printing technology called Intelligent Layering(R). Intelligent Layering technology is the driving force of the company’s printers, which are exclusively used as a service to customers. In February 2022, 3DEO unveiled its next-gen printer, Saffron, equipped with the Intelligent Layering technology. At less than 10 microns nominal, they spread the finest particle size metal powder. Depending on part geometry or print speed required, the printer can automatically vary layer thicknesses anywhere from 50 microns to 250 microns.

Future materials

Joining 17-4PH stainless steel, 316L marks the company’s latest expansion in the materials division, with a growing list of new materials undergoing testing currently, and set to release in 2023. Among those metals in development is pure copper launching in Q2.

“3DEO has been qualifying new materials in partnership with some of the industry’s leading suppliers,” stated Mahmood Shirooyeh, 3DEO’s Senior Materials Scientist. “I am extremely proud of the team, and excited to offer a broader selection of metallic materials to customers and help them develop premium products.”

About 3DEO

3DEO is a manufacturer of 3D-printed precision metal components made with its patented metal 3D printing technology: Intelligent Layering®. They created the Manufacturing Cloud™, an end-to-end manufacturing platform built to scale 3DEO’s proprietary metal 3D printers into mass production through software, 3D printing, robotics, automation, augmented reality, and materials innovation. 3DEO is ISO 9001:2015 certified.