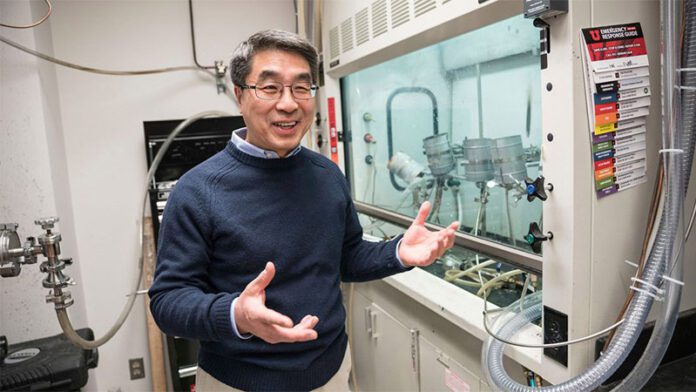

Zhigang “Zak” Fang, FAPMI, materials sciences and metallurgical engineering professor at the University of Utah, is the recipient of the prestigious Humboldt Research Award. Fang has developed a breakthrough technology that can produce high-quality, low-carbon emitting titanium powder at a significantly reduced cost. Known as the Hydrogen Assisted Metallothermic Reduction (HAMR) process, the technology is based on the discovery of new science about the effects of hydrogen on the stability of titanium solid solutions with high oxygen content (up to 14wt%.)

Fang’s research, which led to the HAMR technology, promises to improve energy efficiency drastically. The HAMR process can produce primary titanium metal from either minerals or from titanium scrap. The result is that high-oxygen titanium scrap is transformed into low-oxygen titanium powders that meet or exceed stringent aerospace and biomedical industry standards.

Titanium powder can be used for additive manufacturing or utilized by powder metallurgy to manufacture products in a broad range of demanding applications, including aerospace, defense, biomedical, and other civilian applications, with dramatically increased sustainability.