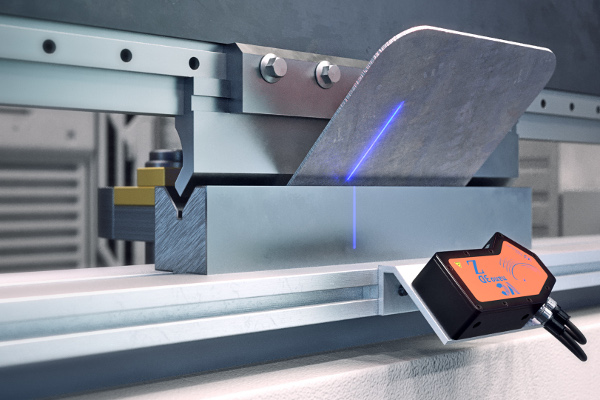

Vision Components provides powerful OEM laser profilers for checking the angular accuracy in sheet metal bending press brakes. The VCnano3D-Z 3D line sensors reach measuring rates up to 400 Hz and a typical accuracy of <±0.1°. They can be directly connected to the machine’s PLC for real-time control of the contact pressure, to boost productivity and efficiency of press brakes.

Notably, Vision Components’ 3D laser triangulation systems operate autonomously, without an external computer. This provides customers with an extremely robust, low-maintenance, and cost-effective solution. Featuring a compact IP67 housing and a large field of view, VCnano3D-Z sensors are easy to integrate and can be used with different dies without any conversion or adjustment. The blue high-performance laser and Vision Components’ proprietary ambient light suppression technology ensure reliable detection on shiny and reflective surfaces. The embedded vision system’s 3D analysis is also designed to correctly detect perforated metal, checkered plate metal, and brushed aluminum. The embedded vision pioneer Vision Components ensures the long-term availability of its products and supports machine builders and manufacturers of inspection systems in their application integration.