Equinor and its project partners have officially decided to move forward with the execution phase of the United kingdom’s first two carbon capture and storage projects.

By Joanne McIntyre, Stainless Steel World

Located in Teeside, the Northern Endurance Partnership (NEP) and Net Zero Teesside Power (NZT Power) are the first two carbon capture and storage (CCS) projects to be realised in the UK. “It is a major milestone to have agreed to the Final Investment Decision on two of the UK’s first carbon capture, transport and storage infrastructure projects. This demonstrates how the industry, alongside the UK Government, have progressed a business model for new power supply and carbon capture, transport and storage services to decarbonise the most carbon-intensive region in the UK”, says Irene Rummelhoff, executive vice president of Marketing, Midstream and Processing at Equinor.

The CCS projects will be up and running in 2028. NEP, in which Equinor is a key partner, is the CO2 transportation and storage provider for the East Coast Cluster (ECC), one of the UK Government’s first selected CCS clusters.

Stainless steel ideal for CCS

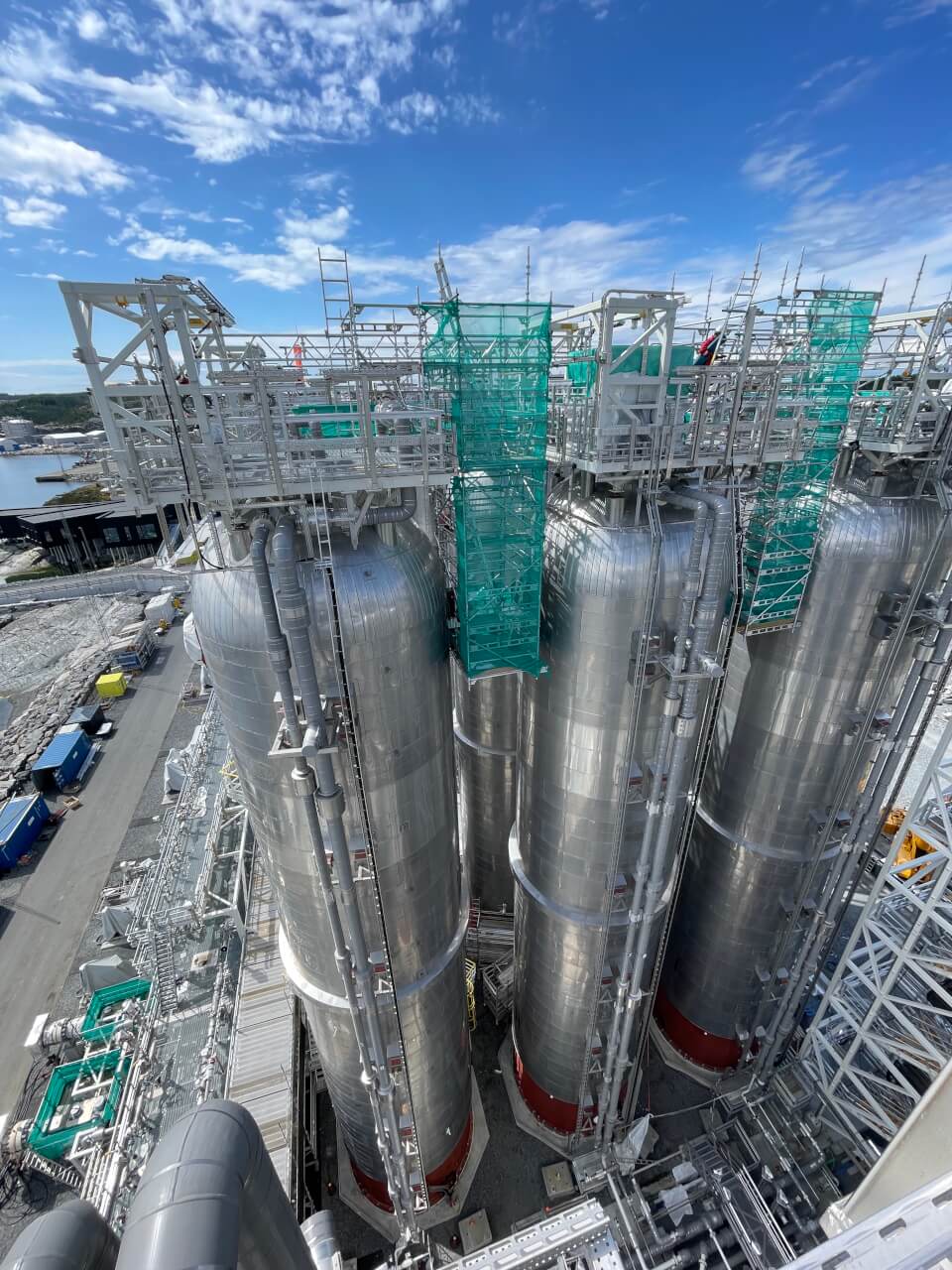

Stainless steel is a dependable, robust, and long-lasting material, making it an ideal choice for every stage of Carbon Capture, Utilization, and Storage (CCUS).

It plays a critical role across the CCUS value chain, from the equipment used to extract CO2 to the pipelines that transport it and the temporary storage facilities required for transit. While pure CO2 is not inherently corrosive, gas streams often contain impurities such as hydrogen sulfide (H2S), chlorides, and sulfides, as well as solvents used in carbon extraction processes. These elements can pose significant corrosion challenges over time. Stainless steel’s exceptional corrosion resistance makes it uniquely suited for these demanding conditions. Its adaptability allows it to perform reliably in environments characterised by fluctuating high pressures and low temperatures, ensuring safe and efficient operations throughout the CCUS process.

Key market

The Teeside project includes a CO2 gathering network and onshore compression facilities, as well as a 145km offshore pipeline and subsea injection and monitoring facilities for the Endurance saline aquifer located around 1000m below the seabed. It could transport and store up to 4 million tonnes of captured carbon dioxide emissions per year from three Teesside projects initially, rising to an average of up to 23 million tonnes by 2035 with future expansion of the East Coast Cluster.

“This is a major step for both Equinor and the UK, helping to decarbonise the country’s industrial heartlands and achieve its net zero ambitions whilst providing jobs and supply chain opportunities,” says Alex Grant, UK country manager at Equinor.

Equinor is also a partner in NZT Power, which is part of the East Coast Cluster. NZT Power will be a new first-of-a-kind gas-fired power plant with carbon capture, which supports the ambitions of decarbonisation across the northeast of England’s industrial regions.

The plant will have the capacity to generate up to 742 megawatts of decarbonised, flexible power, complementing a growing share of intermittent renewable power. This capacity is equivalent to the average electricity demand of around 1 million UK homes. It will have a capacity to capture up to 2 million tonnes of CO2 per year for transport and secure storage by the NEP project.

GBP4 billion project

Building work for both projects will be completed by nine leading engineering, procurement, and construction contractors with a combined value of around GBP 4 billion. The work will bring thousands of jobs and wider socio-economic benefits to the north-east of England.

NEP has also been granted government approval to progress development engineering for the Humber Carbon Capture Pipeline (HCCP), the proposed onshore infrastructure project that would transport CO2 from future selected carbon capture projects in the Humber region.

These decarbonisation projects support Equinor’s wider corporate ambition, including a 50 per cent reduction in operated emissions and 50 per cent gross capex investment in low carbon and renewable technologies by 2030.

About this Featured Story

Appearing in the February 2025 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.