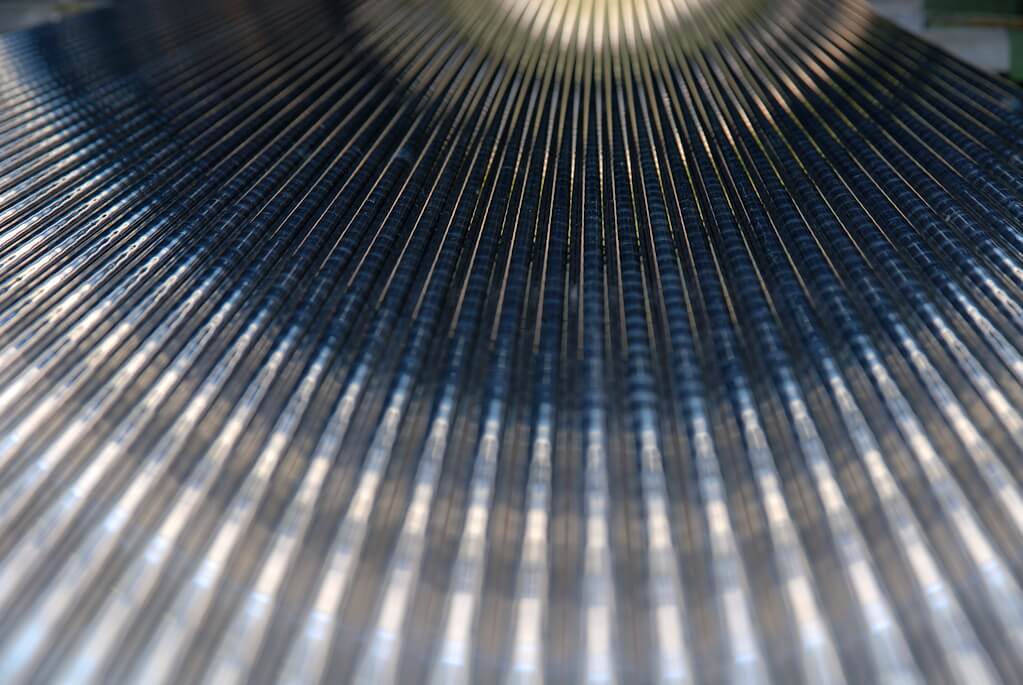

Warehouse of Van Leeuwen Pipe & Tube in the Netherlands

It has been another good year for stainless tubes, pipes, and fittings. The sector’s strength in traditional industries such as oil and gas, coal, nuclear and petrochemicals is matched by its importance for the new-energy sector, including hydrogen, carbon storage and renewables.

By James Chater

Introductory

The low/zero-carbon energy future affects the stainless-steel industry in numerous ways. There has been a trend towards green (decarbonized) steel production, and the recyclability of stainless steel makes it highly suitable during the energy transition. Perhaps even more importantly, stainless steel is crucial for the new-energy sectors

of hydrogen, CCUS and renewables, without however relinquishing its role in the traditional industries such as gas-fired power plants, petrochemicals, or oil & gas. The tubes, pipes, and fittings (TPF) sector is especially geared towards catering for both the new and the old industries.

Outlook

Industry surveys predict a rosy future for the TPF sector: one survey predicts an expansion of 6.49% per year between 2023 and 2030 (1), driven mainly by economic growth in China and India. In 2022 a forecast predicted that the stainless TPF market would grow by an estimated 4.53% per year between 2023 and 2030 (2). This optimism seems to be supported by good company results. For instance, Mannesmann Stainless Tubes (MST) had “a good year overall” in 2023, with an excellent first half, but some weakness in its distribution business in the second half. It reports strength in its aerospace, medical, gas, and nuclear sectors, and sees potential in small nuclear reactors, CCUS and (further down the road) hydrogen. It also noted that higher energy costs are affecting the competitiveness of European producers of both stainless-steel and other items.

Tubacex improved its EBITA by 39.3% year on year in September 2023, with a 21.8% increase in sales. The Spanish company has a strong commitment to sustainability, specializing in hydrogen and CCUS (carbon capture, utilization & storage), as well as a secure position in the oil & gas and petrochemical sectors. Alleima’s Q3 2023 report indicates revenue increases of 8% and organic growth of 5%. The company is heavily invested in products for the oil & gas and chemical & petrochemical sectors and is also active in the hydrogen field. Van Leeuwen Pipe and Tube reported record sales and profit for 2022. (Its figures for 2023 are not yet available.) Vallourec reported good results for 2023, with increased in sales volumes driven by higher shipments in North America and the Eastern Hemisphere.

Other companies that are expanding include Ukraine’s Centravis which, despite difficulties in electrical supply and other disruptions caused by the war, is forging ahead with a new, fully automated production site in Uzhgorod in the west; and South Korea’s SeAH, which is building a stainless-steel seamless pipes and tubes production facility in Saudi Arabia that will start operating in 2025.

Traditional industries

Oil & gas

The world’s thirst for energy is such that renewable energy installation scarcely seems to dent demand for oil and gas. Gas exploration and extraction is benefitting from the decreased availability of Russian gas. Among the most dynamic regions are Iraq, Brazilian pre-salt deepwater, Angola, and many others. Orders are pouring in for OCTG tubes from Alleima, Tenaris, and Vallourec, umbilicals from Alleima and Aker Solutions, and casing and tubing from Tenaris. Some of the recently announced projects are associated with decarbonization initiatives. For instance, TotalEnergies’ Gas Growth Integrated Project in Iraq, of which Vallourec is a supplier, involves flared gas recovery for power generation, seawater treatment and a solar power plant. Oil & gas extraction often goes hand in hand with CCUS projects.

Chemical and petrochemical

In the high-growth economies of the Middle East and Far East, chemical and petrochemical products are in great demand. This is why BASF is building an integrated petrochemicals plant in Guangdong, China, and why Alleima is boosting its capacity in tubing products, including high-alloy heat exchanger (HE) tubes, by building a cold-finishing facility in Zhenjiang, China. MST has just strengthened its position by hiring a new team to cover this market.

Nuclear

Nuclear fission has been undergoing reappraisal because of rising gas prices and the need to reduce CO2 emissions. A recent breakthrough is the Nuscale Small Modular Reactor (SMR), a type of pressurized water-cooled reactor that can be built in a far shorter time than standard reactors, allowing the nuclear industry to respond more quickly to demand. As MST told me, the SMRs “require solutions beyond today’s feasibility in terms of grades and shapes, through an integration of design and material properties at the highest level.” In 2023 Alleima is supplying 200 km of steam generator tubes for the first SMR, and many more reactors are anticipated in the USA, in association with district heating, desalination, and hydrogen production.

Another company that has been active in nuclear energy is Tubacex. EDF was experiencing stress-corrosion-cracking issues in its French nuclear power stations, and Tubacex affiliate IBF (based in Italy) supplied forged and machined tubular components, fittings, and connections to overcome the problem.

Heat exchangers

A sure path towards decarbonization is to improve the efficiency of HEs. Advanced specialized materials are essential to achieve this goal. Alleima is evolving a programme to allow the most advanced HEs to reach customers in Europe, Africa and the middle East within eight weeks. The programme involves HEs made of duplex grade 2205, super-duplex 2507, 254 and Sanicro® 35. This last, with its superior strength and corrosion resistance at high temperatures, was applied for the first time in a biogas facility in Texas, in HE tubes that will replace failed 316L tubes.

The facility converts and upgrades biogas into renewable natural gas. The importance of an effective replacement service offering higher-alloy tubes is highlighted by MST’s decision to offer an eight-week delivery programme for specialized HE tubing.

New-energy industries

Hydrogen

Of all the types of renewable energy, hydrogen is possibly the one that is growing the fastest, as it is important for both power generation (including energy storage) and transport.

Future growth depends on funding, so projections should be treated with caution, but two recent reports present an optimistic picture: Deloitte projects that hydrogen will grow to become a USD 1.4 trillion market by 2050, while Businesswire projects an annual growth rate of 7.15% from 2023 to 2040, with the electrolytic process segment boasting a rate of 9.38%. In 2022 the ammonia production segment accounted for over 50% of market share (3). Suppliers committed to the hydrogen industry include Vallourec, Mannesmann, Tubacex, Nippon Yakin Kogyo, and Alleima. Vallourec, a supplier of pipes for H transport and storage, is developing new industry standards and has carried out tests qualifying the fracture toughness resistance certain steel grades for OCTG pipes, line pipes and pressure vessels exposed to H2. It has invented an underground modular storage system called Delphy. Tubacex is collaborating on the H2SALT project, in which hydrogen will be stored in underground salt caverns.

CCUS

Carbon Capture Utilization & Storage is considered an important contribution towards decarbonization. Carbon capture capacity is due to rise sixfold between 2022 and 2030, though the 50 projects announced for this period will not suffice to meet the Net Zero Scenario (4).

In early 2022, Neptune Energy asked Vallourec to test materials for safe injection of CO2 in depleted wells in the Dutch North Sea. Vallourec is also working with Evonik to develop tubular solutions for the CCUS industry. Tubacex has developed CRA tubular products (OCTG) for CO2 injection. Nippon Steel is collaborating with Mitsubishi and ExxonMobil on a programme for the Asia Pacific regions. MST is also developing its CCUS business.

Renewable energy

Both solar and geothermal require CRA tubing to function. Geothermal is especially promising as technology is changing quickly as engineers learn to drill ever deeper into the earth to tap the magma that provides the heat to generate electricity. Vallourec has recently developed VAM® connections qualified for up to 350°C under thermal cycles, and Vacuum Insulated Tubing (VIT) for closed-loop geothermal systems which produce heat and power with minimal losses. Butting recently received an order for two types of casing for a new geothermal project in the Salton Sea, California, one made of super-duplex, the other of alloy 625.

Conclusion

Tubes, pipes and fittings made of stainless steel or CRAs are essential in both traditional and new (decarbonization) industries. As time goes on, the market share of the latter will only increase.

Acknowledgements

My thanks to Patrik Schraven, General Manager Marketing and Business Development of MST, for his insights.

References

(1) www.einnews.com/pr_news/644942862/pipe-fittings-market-forecast-2023-2030-growth-potential-and-outlook.

(2) www.zionmarketresearch.com/report/stainless-steel-pipes-and-tubes-market.

(3) https://www2.deloitte.com/id/en/pages/about-deloitte/articles/emerging-green-hydrogen-market.html; https://www.businesswire.com/news/home/20230911450901/en/Global-Hydrogen-Market-Set-for-Significant-Expansion-Projected-Value-of-761.3-Billion-by-2040—ResearchAndMarkets.com

(4) https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage

About this Featured Story

This Featured Story appeared in Stainless Steel World March 2024 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format) – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.