Thermal spraying is an advanced manufacturing method in which material in powder or wire form is melted and sprayed onto a surface to create a coating with specific properties. Alleima is now investing in this technology to develop new products in the field of sustainable energy.

Text & images by Alleima

Thermal spraying can be utilised for products in the field of sustainable energy, such as the production of components for green hydrogen through electrolysers. Alleima is in dialogue with several interested customers, and the first prototype of the coated material has already been sent to a customer. Thermal spraying enables coatings with specific properties that are crucial for improving products such as electrolysers for the production of green hydrogen. Green hydrogen, produced by the electrolysis of water using renewable energy, plays a central role in the transition to a carbon-free economy. Thermal spraying enables the development and industrial production of key components in an electrolysis stack.

“This investment is part of the company’s long-term strategy to drive innovation and create sustainable solutions. It is a pilot that will primarily be used for research purposes but

will also be used for small-scale production when possible. By using this technology in our manufacturing processes, we can offer advanced materials and components that meet the high demands of hydrogen production. This initially includes the development of components for electrolyser cells, but also other applications that require robust and durable coatings,” says Tom Eriksson, Head of Strategic Research at Alleima.

Cost-effective solutions

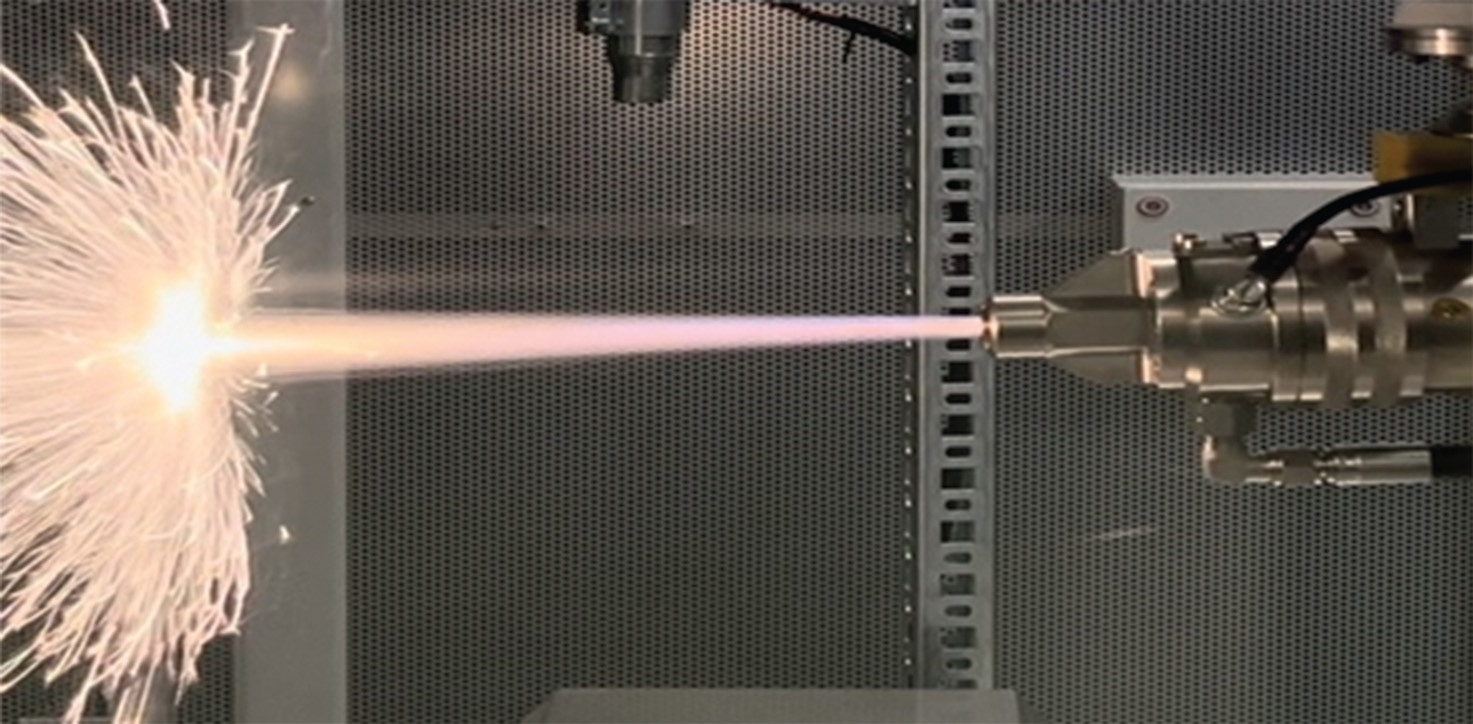

The technology will eventually make it possible to develop products that replace expensive material solutions. This will help to reduce the cost of electrolyser stacks, which in turn can promote the increased use of green hydrogen and thus reduce carbon emissions. The process uses a heated material in powder form that is propelled at high speed onto the surface to be coated. When the powder lands on the surface, the powder particles deform and solidify. Typically, multiple layers are sprayed onto the surface to achieve the desired properties.

“Our goal is to create groundbreaking solutions for a cleaner and greener world. We are currently in contact with several potential customers who are testing our prototype material in their test facilities,” says Mikael Blazquez, EVP and Head of Strategy, M&A and IT at Alleima.

Rapid process

One of the advantages of thermal spraying is that it is a fast process that can be used in many different areas, depending on the base material used. Common materials include metals, metal alloys, composites, and ceramics. The coatings can protect components from wear and corrosion, and they can withstand high temperatures, making them ideal for industrial applications. The coatings can also enhance the properties of the component, such as friction, electrical conductivity or insulation. The technology can improve the efficiency and sustainability of hydrogen production, among other things, which in turn supports the global transition to renewable energy and reduced carbon dioxide emissions.

About this Tech Article

Appearing in the November 2025 issue of Stainless Steel World Magazine, this technical article is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new technical articles with our Stainless Steel community. Join us and let’s share your technical articles on Stainless Steel World online and in print.