Imagine transforming ordinary 316 stainless steel so it performs like a high-end nickel alloy, not by coating or cladding it, but by changing the metal from within. That is the promise behind TerraBarrier, a new barrier technology that could redefine how metals resist hydrogen, ammonia, and corrosion in harsh environments. Developed from research at Chalmers University and Harvard University, TerraBarrier creates a gas-induced, diffusion-grown layer that becomes an intrinsic part of the alloy. Dr Anna Carlson, CTO, and Jonas Wallmander, CEO, explain how the technology works and what it could mean for the future of stainless steels.

By Joanne McIntyre, Stainless Steel World

Rethinking how metals are protected

Hydrogen, ammonia and similar media impose a well-known set of challenges on metals: high-temperature corrosion, hydrogen permeation, and, in some cases, embrittlement. These effects can force engineers toward expensive materials, particularly in heat-exchanger and gas-turbine components.

According to Jonas, this changing landscape helped motivate the work that led to TerraBarrier.

“As new energy systems develop, designers are encountering environments that are harsher than stainless steels were originally intended for. At the same time, industry is under pressure to control cost. We saw a need for a different kind of solution; one that didn’t rely solely on switching to higher-alloyed materials.”

How TerraBarrier works

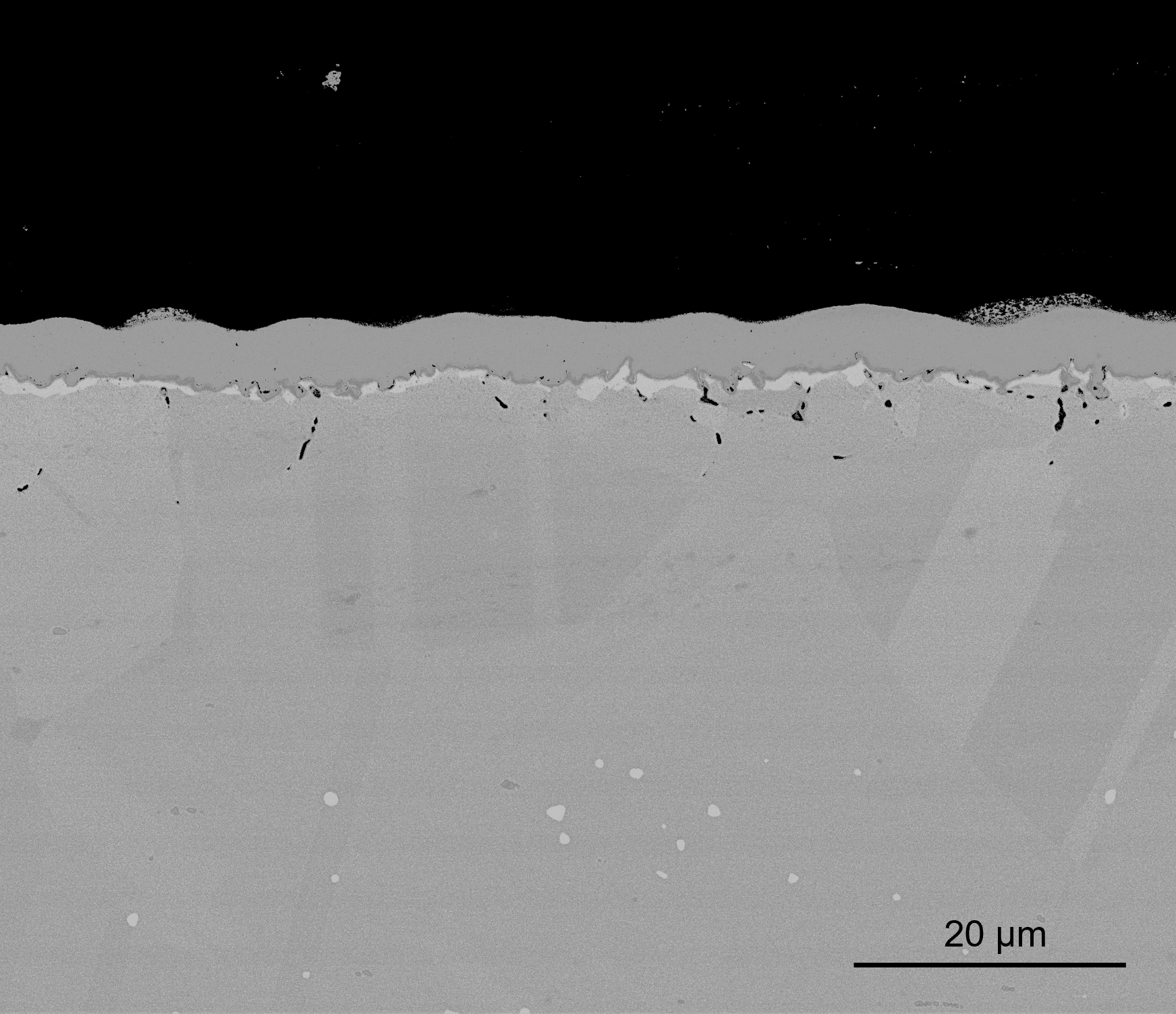

TerraBarrier is produced through a controlled gas-metal interaction. Instead of depositing an external layer, the treatment reacts with chromium and other constituents already present in the alloy. This forms a thin, continuous barrier at the surface, but crucially, one that grows from within rather than adhering from above.

Dr Carlson explains: “The layer is metallurgically bonded to the substrate because it originates from the alloy itself. This gives it high stability and makes it extremely adherent to the substrate. Since it is diffusion-grown, it conforms to complex geometries down to 0.1mm in diameter, including internal passages.”

The resulting surface is reported to be:

- thin enough to retain flexibility

- highly adherent

- low in porosity

- resistant to cracking, even during forming

Performance in hydrogen, ammonia, and acidic environments

Early testing has shown promising behaviour in hydrogen service, particularly in high-temperature conditions where hydrogen permeation is a concern.

“We treated a heat-exchanger and saw hydrogen permeation reduced by a factor of 1000 compared to untreated material,” says Dr Carlson. “The same customer had already tried several commercial coatings; none came close to that level of reduction.”

At lower temperatures, TerraBarrier is also reported to inhibit hydrogen ingress that can lead to embrittlement.

Ammonia exposure is another area of interest. Stainless steels can degrade rapidly under high-temperature ammonia, yet TerraBarrier-treated samples showed no detectable nitrogen uptake during high-temperature exposure of 316, 253MA and 625 materials in pure ammonia.

Corrosion tests according to G48 standard show excellent acidic corrosion behaviour. Coated standard 316 exhibited a pronounced improvement in pitting resistance and crevice corrosion performance under harsh acidic environments.

Interaction with defects

An unexpected result arose during testing on welded tubes: the protective layer also formed inside small weld defects. A sample tube with a micro-crack at the weld position showed the barrier extending into the feature, effectively sealing it. The team believes this may help reduce susceptibility to localised attack initiated at welded areas or machining defects.

“Many users are understandably nervous about small surface imperfections,” notes Jonas. “In trials, TerraBarrier not only coated the surface but penetrated into the defect and established a continuous barrier there as well. Even gaps and structures on the micro-scale are effectively coated.”

Material scope and potential substitutions

The process currently applies to stainless steels and nickel- and cobalt-based alloys containing at least 10% chromium. TerraBarrier aims to extend the lifetime and slow degradation in harsh environments, without altering the surface roughness or base alloy composition.

Because of this improved performance, some users are investigating whether TerraBarrier-treated 316 stainless steel could replace more costly materials in certain applications.

TerraBarrier is a young technology – the company was founded only two years ago – but approximately forty industrial partners are now evaluating it. Much of the interest lies in high-temperature applications: heat exchangers, burner components, gas turbines and jet-engine parts.

“We’re realistic,” says Jonas. “Industry tends to be cautious with new processes. That’s why we’ve been focused on third-party validation and field trials. So far, the results are encouraging.”

Early adopters include companies exploring the possibility of replacing titanium plates with TerraBarrier-treated 316 stainless in saline environments — a shift that could deliver substantial cost savings if validated over long-term testing.

The company offers two implementation approaches: a service in which components are processed by TerraBarrier, and equipment sales combined with licensing the technology for facilities that wish to integrate the treatment into their own production.

Looking ahead

While TerraBarrier’s potential is drawing attention from several Fortune 500 companies, the team is cautious not to oversell. “We’re still gathering long-term performance data,” says Wallmander. “But the early results have been consistent – high stability at elevated temperatures and an impermeable barrier against hydrogen and ammonia.”

For industries pursuing decarbonisation through hydrogen and other challenging media, that stability could make a real difference. As Dr Carlson sums up, “Our goal isn’t to replace stainless steel – it’s to unlock its full potential in the next generation of clean-energy systems.”

TerraBarrier represents a shift from coating to conversion: an inward, diffusion-grown barrier that forms from the metal itself. If ongoing trials confirm its performance, it could enable engineers to use economical stainless steels in roles once reserved for exotic alloys, reducing both cost and environmental impact while extending component life.

For information, please go to https://terrabarrier.com/

About this Featured Story

A Featured Story like this is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.