STILFOLD has announced a new partnership with Alstom, which will see the companies explore how STILFOLD’s origami-inspired manufacturing technology could be used to make building trains more environmentally sustainable.

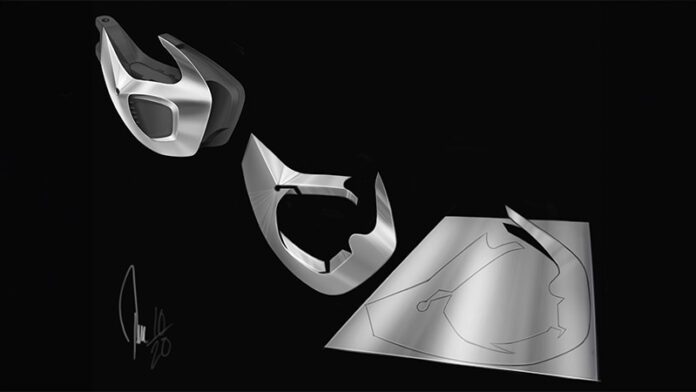

STILFOLD’s patented manufacturing technology, dubbed “industrial origami” involves the use of robotic arms to fold flat sheet metal over curves to form strong and sustainable new structures, using minimal component parts. The technology removes the need for cutting, welding and joining, reducing material waste, energy consumption and production time while increasing structural strength.

STILFOLD will work with Alstom to explore how its innovative steel bending technology could improve the structures and components in trains are produced to significantly reduce the climate impact of the process.

Over the coming months, STILFOLD and Alstom will jointly review existing manufacturing solutions at Alstom to analyse and identify areas where the greatest impact can be achieved by implementing the STILFOLD technology. STILFOLD will enable Alstom to use fewer raw materials, reduce the weight of different components and improve the strength and durability of their trains’ structures.