A DeP converter from Siemens has commenced operation at the Chinese steel producer Tangshan Stainless Steel, a subsidiary of Tangshan Iron & Steel Group. The converter installed at the Tangshan plant serves to reduce the crude steel’s phosphorus content. Tangshan produces high-grade carbon steels, which are processed further to high-strength sheets for the automobile industry at a cold rolling complex newly constructed by Siemens.

Photo courtesy of Siemens AG

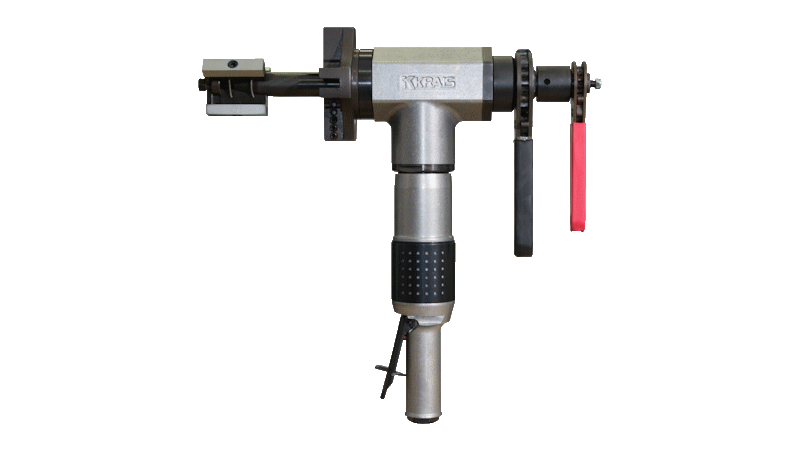

Tangshan Iron and Steel belongs to the Hebei Iron and Steel Group, China, with annual production of around 46Mt in 2013. Last year, Siemens had received the order from Tangshan Iron and Steel to supply a complete cold rolling mill for the Tangshan plant. The plant is designed for annual production of 1.6Mt of cold rolled strip. Siemens converted an existing AOD converter to the DeP converter. The converter possesses a tapping weight of 110t and can be used for decarburisation. Siemens was responsible for engineering, supplied the process automation and supervised installation and commissioning. Moreover, Siemens advised the operating personnel on how to handle the new process.