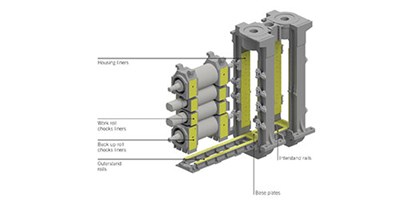

Correct mill stand geometry is essential for effective and accurate gauge control, strip/plate quality and maintenance of the mill and its associated parts, like bearings, chocks, hydraulic clamps, bending and balancing systems as well as gauge control systems.

Housing windows of new mills create a stable and accurate location for roll chocks. After many years of service, the condition and alignment of mill stands deteriorates due to various factors, such as wear, corrosion, erosion, or even foundation adjustment. This leads to problems attributed to incorrect positioning of work and back-up rolls and excessive movement of the roll chocks within the mill stand.

On-site machining is the most technically effective and long-lasting solution to the problems highlighted above. By machining the surfaces of the housing it will be able to create a flat, parallel surface which is consistent throughout the height of the window and between the operator and drive side housings. The process also removes any surface corrosion, ensuring the new mounting faces are free from any defect. This process requires the use of tailor-made machining tools along with a team of highly skilled technicians and engineers that Danieli Service is able to deploy all around the world.