The Bundesanstalt für Materialforschung und -prüfung (BAM) research institute has developed a rapid colour test to detect corrosion in stainless steels

Text & images by BAM

The corrosion protection of stainless steel is based on the formation of a chromium oxide layer which is only a few atomic layers thick; the so-called passive layer. Areas with a disturbed or incompletely formed passive layer are prone to unwanted corrosion reactions. As iron ions are dissolved the surface appearance may be impaired and damage caused, potentially creating a safety risk.

Early damage detection

A research team from BAM’s Corrosion and Corrosion Protection Division has developed a test that reveals faulty surfaces in stainless steels.

KorroPad consists of a test pad with an indicator solution containing an activator which, by means of a binding agent, is kept in a gel-like condition. The pad simulates a moisture film at the surface of the test object and maintains a defined corrosion system. The presence of iron ions turns the KorroPad’s colour blue, revealing an incomplete passive layer (Figure 1). The test method is suitable for most common stainless steels; for lower-alloyed steels (e.g. 1.4003), the test needs to be adapted.

Application

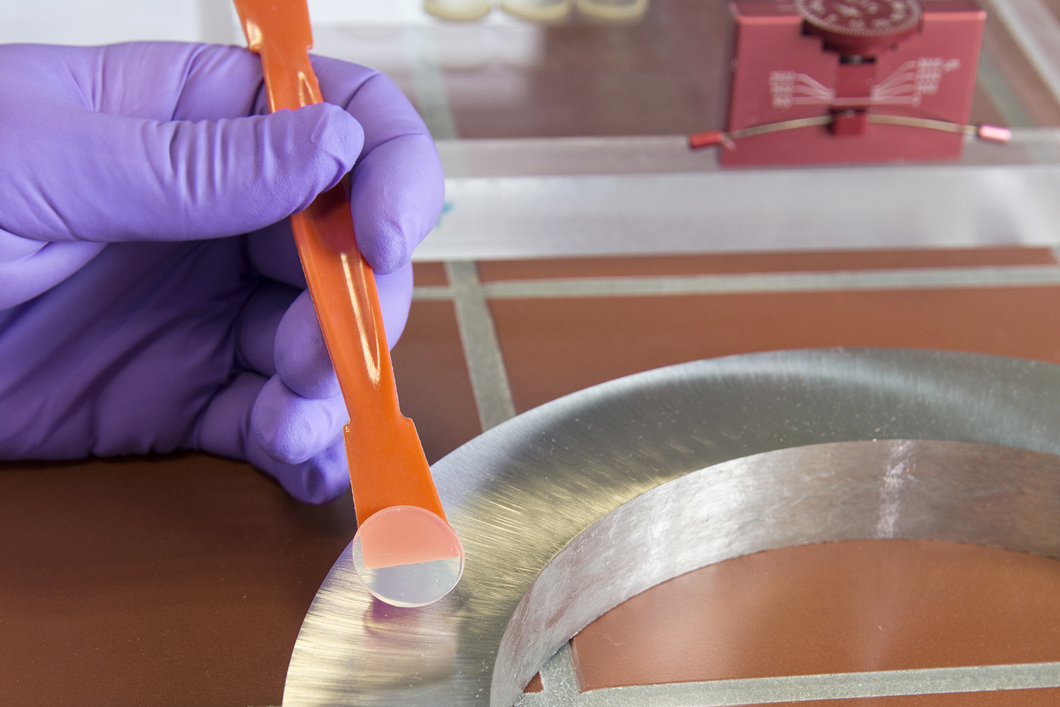

Three pads, each about the size of a five-cent coin, are required for each test. The pads are pressed onto the cleaned surface and peeled off with a spatula after 15 minutes. If the passive layer is faulty, the indicator reacts with the iron ions in the material during the test, and blue dots appear on the slightly yellowish pads. Each dot indicates spots where the protective passive layer has not formed properly on the steel surface. The KorroPad method can be used in the temperature range +5 to +50 °C. Best comparable results are achieved at temperature +20 °C ±5. Testing times are normally 15 minutes but can be adapted if necessary. The test method can be employed for optimisation of surface treatment processes as well as for incoming and outgoing goods inspection.

Evaluation of results

The KorroPad will not indicate a colour change on stainless steel surfaces with a well-formed passive layer. It can be assumed that the passive layer has been optimally formed if the test results do not reveal any corrosion indication.

Single, minimal indications do not necessarily denote general corrosion susceptibility but could occur statistically at technical surfaces. In this case, a closer look at all three comparative pads is recommended. If necessary, a further three pads should be applied elsewhere and assessed. Numerous, especially larger indications denote local disturbances of the passive layer. In this case, specific actions for surface improvement should be performed. The KorroPad test method is a comparative test, providing indications of surface requirements for practical use (Figure 2). If necessary, the basis, i.e. the criterion for a good/bad evaluation, can be adapted for specific problems.

Easy and uncomplicated

In addition to being quick to carry out, KorroPad has further advantages: even non-professionals can apply it due to its easy application and simple evaluation, and the test leaves no residues or traces on the surface. The KorroPad method developed by BAM helps prevent safety problems due to defective material before further processing.

Bundesanstalt für Materialforschung und -prüfung (BAM) is a senior scientific and technical Federal institute with responsibility to the German Federal Ministry for Economic Affairs and Climate Action. The KorroPad can be ordered at the BAM Webshop: webshop.bam.de/webshop_en

About this Tech Article

This tech article appeared in Stainless Steel World, October 2023 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format) – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.