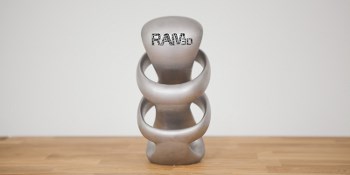

Rapid Advanced Manufacturing (RAM3D) has opened a new facility in Tauranga’s Tauriko Business Park for making metal additive manufacturing more accessible to the Australian and New Zealand markets. RAM has been collaborating with global engineering technologies company Renishaw and, as a result, is using several AM250 metal additive manufacturing systems in its Tauranga facility.

RAM3D has the biggest Australasian centre for 3D metal printing. RAM3D’s new facility allows companies from a range of sectors, including aerospace, defence, consumer and industrial, to explore the benefits of metal additive manufacturing.

The diversity of the parts RAM3D manufactures ranges from titanium knives used by the Team Emirates America’s Cup crew to customised handlebar extensions for the New Zealand Olympics cycling team, as well as titanium lugs for high-end Australian custom bike maker Bastion Cycles.

RAM3D is planning to continue its growth and accommodate for 20 metal additive manufacturing systems by the end of 2020.