INEOS Olefins & Polymers Europe has secured EUR 3.5 billion in financing to build the most environmentally sustainable cracker in Europe.

By Joanne McIntyre, Stainless Steel World

Project ONE is the largest investment in the European chemical sector for a generation. The new ethylene cracker, to be located in Antwerp, Belgium, will have the lowest carbon footprint of all European crackers; five times better than the worst in Europe and two times better than the best.

The plant will have the capability of operating entirely with low-carbon hydrogen, as well as room for a carbon capture facility and future electric furnaces. As soon as enough green hydrogen becomes available, the cracker will have a zero carbon footprint. Jason Meers, CFO INEOS Project ONE stated: “This is an incredibly important moment for INEOS. Our ethane cracker will set new environmental standards for Europe as well as help revitalise the whole of the European chemical industry.”

Largest investment for a generation

Project ONE is the largest investment in the European chemical sector for a generation. The plant will have the lowest carbon footprint in Europe, three times lower than the average European steam cracker, and less than half that of the 10% best performers in Europe.

“Project ONE is a game changer for Europe. It will bring new opportunities to the chemical cluster in Antwerp as well as strengthen the resilience of the whole of the European chemical sector,” explains Mr Meers.

Supported by 21 commercial banks, the deal validates the strong commercial rationale of the project and its leading environmental characteristics. The debt will be drawn in stages to support the spend profile of the project through to completion.

It comprises EUR 1.5 billion of uncovered debt, EUR 1.2 billion of covered facilities from export credit agencies UKEF, Cesce and SACE; and an EUR 800 million covered tranche

of which up to EUR 500 million is guaranteed by Gigarant (a vehicle of the Flemish government that provides loan guarantees).

Meers continued: “We are thrilled to reach this milestone and secure this funding. Bringing together such a large number of environmentally focused commercial banks alongside four governmental agencies demonstrates the huge importance of the project.” Project ONE is part of a EUR 4 billion investment plan for the Port of Antwerp. The cracker will produce ethylene,

a vital raw material for a wide range of products essential to our daily lives. These range from insulation to lightweight vehicles, plastics for medical, healthcare and food hygiene, as well as technology for renewable energy.

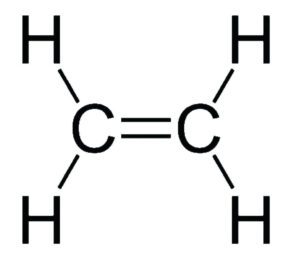

What is ethylene?

Ethylene is a basic building block in the chemical industry and a primary link between chemical companies and petroleum refiners. An ethylene or olefin plant will mostly produce ethylene, but also breaks the feedstock into other usable byproducts, such as propylene, butadiene and gasoline.

Crackers separate ethane from natural gas to produce ethylene, the building block of plastics and other industrial products. The plants use extreme heat to “crack” the molecular bonds in ethane to produce ethylene. Ethylene is further processed into a resin, which is used to produce plastic products.

Stainless steels in ethane crackers

Stainless steels are used in several critical components of an ethylene cracker, including the furnace tubes, quench water systems, and cracking coils. Furnace tubes are exposed to high temperatures and corrosive gases, making them susceptible to oxidation and carburisation.

Stainless steels are used in several critical components of an ethylene cracker, including the furnace tubes, quench water systems, and cracking coils. Furnace tubes are exposed to high temperatures and corrosive gases, making them susceptible to oxidation and carburisation.

Stainless steels with high chromium content, such as 310 and 316 grades, are often used in furnace tubes because of their excellent resistance to these conditions.

Quench water systems used to cool the process gases in an ethylene cracker also require materials that can withstand the highly corrosive environment. Stainless steels such as duplex and super duplex grades are often used in these systems because of their superior resistance to corrosion.

Finally, cracking coils are the heart of the ethylene cracker, and they are subjected to high temperatures and stresses during operation. Stainless steels with high nickel content, such as Inconel and Hastelloy, are often used in these coils because of their excellent high-temperature strength and resistance to corrosion and cracking.

About INEOS

INEOS is a global chemical company making the raw materials and energy used for everyday life. It comprise 36 businesses with 194 sites in 29 countries throughout the world.