Until recently, precise imaging methods to aid in the selection of inert gas parameters during welding were used exclusively in academic research. Wolfram Industrie has managed to bridge the gulf between academia and weld shops to optimise TIG welding processes for industrial applications.

By Matthias Schaffitz, Application Engineer at Wolfram Industrie

Downstream inspection and rework account for about 50% of the TIG welding cost on average. With stricter quality standards, the proportion of these work steps quickly increases to two-thirds of the production process because tighter inspection cycles and more elaborate repair welding may be required. The effort can be considerably reduced through the selection of the inert gas parameters. However, these factors can usually be evaluated only based on their effects. A correction is possible at best for the next workpiece and may necessitate changes to other process factors.

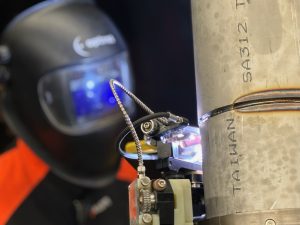

Streak methods can help determine the inert gas parameters in a timely manner. However, precise imaging methods have been used exclusively in academic research to date. Their transfer to industrial practice was hardly feasible. Wolfram Industrie has built a bridge across this seemingly insurmountable chasm between industry and research. Through a combination of streak methods and sensor measurements, Wolfram Industrie’s Swiss welding laboratory now offers development services and consulting to optimise the TIG welding process especially for industrial applications.

Avoiding weld defects

If the electrode oxidises, for instance, because the inert gas flow setting is too low, the component oxidises as well. TIG welding takes place in a closed system with interactions between individual components: the tungsten electrode, welding seam and inert gas. This is associated with some challenges. Depending on the field of application, a porous or otherwise defective welding seam on a component, for example, can have fatal consequences. Furthermore, the welding process – joining the components – often occurs relatively late in the value chain. Quality defects that occur at this late stage can, therefore, painfully slow down production as a whole.

Inert gas protection is, however, an influencing variable that cannot be determined intuitively.

Recommendations are usually general in nature and can deviate considerably from the configurations actually required in a specific application. Difficulties such as electrode wear, ignition problems or material defects are often caused by an excessive gas flow that is highly turbulent or by an insufficient flow rate that, in turn, makes the inert gas protection more susceptible to air turbulences and draughts in the workplace. Thus an unsuitable configuration of the inert gas supply quickly turns the TIG welding process into a costly undertaking.

Costly rework and lost production

Rework to correct quality defects that occur in the welding process is one of the biggest cost factors. This includes repair welding to remove peripheral oxidation and thus improve the surface condition. Non-destructive material testing is also performed, for example, testing the porosity of the welding seam in the microscopic range. While oxidation is caused by its namesake oxygen, porosity in the metal is often due to nitrogen or hydrogen. Both can usually be traced back to improperly configured inert gas protection and be eliminated by a process improvement.

Machine availability is also becoming more important with the rising automation level in production. Sophisticated and costly welding cells, orbital systems and automation, in general, require a high rate of capacity utilisation to be economically viable. That being said, the tungsten electrode that is used can throw a monkey wrench in the works. Turbulent gas flows cause even high-grade electrodes to oxidise. This not only affects the quality of the welding seam but significantly increases the production costs as well. Incorrectly adjusted or non-optimised gas volumes and times, therefore, lead to the frequent replacement of worn parts and associated plant shut-downs, significantly limiting productivity.

Yet significant improvements can be achieved even with small adjustments.

More is not always better

Consumption of the inert gas itself is the third cost factor. The assumption that “more is better” adds no value in gas-shielded welding. Quite to the contrary: it has been observed in practice that an excessive gas flow is the root cause of numerous problems. Aside from improving the weld quality, reducing unnecessary gas consumption has a direct impact on production costs.

Significant added costs accumulate quickly, especially when using mixed gases with a high proportion of helium. Up to several hundred euros per production day can be saved by specifically optimising the gas supply for the respective application.

Measuring methods do exist to tailor the shielding gas to specific conditions. However, these are used almost exclusively in academic research today. For industry, this means that the effects of individual parameters can only be determined in practice by observing the respective, usually negative effects. As a complicating factor, the gas itself cannot be seen with the naked eye. Discolouration and wear of the tungsten electrode are the welder’s first indications that the shielding gas flow is improperly adjusted. The more problematic quality defects on the work piece itself, such as porosity, are generally only detected during in-process or downstream volumetric material testing. This means that optimising the parameters can at best affect the next work piece – provided it does not require entirely different process conditions.

New link between academics and industry

Wolfram Industrie is operating a welding laboratory at its site in Switzerland to eliminate the costly trial and error principle. In this laboratory, welding experts can exactly replicate, measure and optimise the environmental conditions for any TIG welding application. To accomplish this, two approaches from scientific research have been adapted for industrial applications. Streak methods – imaging methods from the fluid engineering field – are one approach and can represent the gas and heat flows during active arcing at high resolutions. Sensor measurements are the second approach used at Wolfram Industrie to record, for example, the dynamic pressure, speed and chemical composition of the inert gas. In conjunction with precise position data, the protective gas can thus be measured three-dimensionally and optimised for the specific industrial application under consideration of all environmental conditions and influencing variables.

About Wolfram Industrie

The company was founded in Berlin in 1911 as Wolfram Drahtfabrik GmbH for the manufacturing and processing of tungsten and molybdenum. The company relocated its headquarters to Nußdorf im Chiemgau in 2023 as part of a modernisation and expansion of its production capacities and now has 130 employees. In 2018, the company opened its location in Switzerland. For more information, visit wolfram-industrie.de

About this Tech Article

Appearing in the December 2024 issue of Stainless Steel World Magazine, this technical article is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new technical articles with our Stainless Steel community. Join us and let’s share your technical articles on Stainless Steel World online and in print.