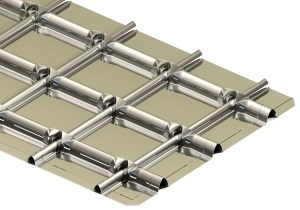

The Polaris icebreaking LNG carrier features three electrically driven ABB Azipod propulsion units, each of which has a four-bladed stainless steel propeller with removable blades

Article by Mr James Chater for Stainless Steel World

Article by Mr James Chater for Stainless Steel World

____

Introduction

One symptom of a healthy industry is how quickly innovation is occurring. By this criterion, LNG looks fit as a fiddle: capacity expansion and innovation both at sea and in material specification indicate that the industryis still growing. Natural gas will play an important role in transitioning from the fossil fuel age to one dominated by renewables. The broadening of the Panama Canal and the opening up of the Arctic region will speed up deliveries, lower prices (at least in the short term) and further globalize the natural gas market.

Markets

Apart from gas-fired power stations, which have been taking an increasing share of the power generation mix since the 1990s, LNG is penetrating new markets. One of these is steel making. Up to now steelmakers have used coke, a type of treated coal, to fuel the reducing process. Now they are looking at natural gas as an alternative. In 2017, China’s Fujian opted to use LNG instead of coal to produce its steel. Some experts predict that in ten years coke will become obsolete, as new technology becomes available to make steel using gas.

Transport is another growth opportunity for LNG. On land, LNG is being increasingly used instead of diesel to power heavy vehicles like trucks or buses. Companies such as Clean Energy are hard at work creating the required infrastructure, especially fuelling stations. For instance, it recently started to collaborate with Total on a scheme to provide leased LNG-fuelled vehicles. And last year an LNG-fuelled truck carrying LNG fuel loaded a trailerat Gate Terminal in Rotterdam.

At sea, LNG-fuelled vessels are now a well established sector. MSC Cruises has ordered its fifth Meraviglia class liquefied natural gas (LNG)-fuelled cruise ship at the STX France shipyard. It will be equipped with dual-fuel engines (diesel/LNG) and also feature a wastewater treatment system. Triestebased Ficantieri will build two new LNGpowered ships for TUI Cruises. Norway’s Vard shipyard will see the construction of the world’s first electric hybrid cruise ice-breaker with LNG propulsion, for which GTT will supply the LNG tanks.

Transport is another growth opportunity for LNG. On land, LNG is being increasingly used instead of diesel to power heavy vehicles like trucks or buses. Companies such as Clean Energy are hard at work creating the required infrastructure, especially fuelling stations. For instance, it recently started to collaborate with Total on a scheme to provide leased LNG-fuelled vehicles. And last year an LNG-fuelled truck carrying LNG fuel loaded a trailerat Gate Terminal in Rotterdam.

At sea, LNG-fuelled vessels are now a well established sector. MSC Cruises has ordered its fifth Meraviglia class liquefied natural gas (LNG)-fuelled cruise ship at the STX France shipyard. It will be equipped with dual-fuel engines (diesel/LNG) and also feature a wastewater treatment system. Triestebased Ficantieri will build two new LNGpowered ships for TUI Cruises. Norway’s Vard shipyard will see the construction of the world’s first electric hybrid cruise ice-breaker with LNG propulsion, for which GTT will supply the LNG tanks.

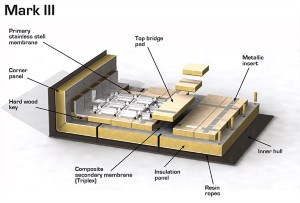

LNG bunkering vessels

Bunkering or fuelling is now a growing application for ships, whether LNG-fuelled or not. Of the four ways of supplying a vessel with fuel – tankto-vessel, truck-to-vessel, vessel-to-vessel and portable tank transfer, vessel-to-vessel (aka ship-to-ship, STS) is now the fastest growing. This rapidly evolving sector was relatively unknown before 2017, but in that year three purpose-built LNGBVs (LNG bunkering vessel) were deployed. By February 2018 five more had entered service and ten more were on order, and several more will be completed in 2019 and 2020. STS transfer allows significantly quicker and more efficient transfer compared with landbased systems, especially considering the size of modern LNG carriers. Several of these ships use GTT’s Mark II membrane design. The largest LNGBV yet ordered is the 18,600 m3 fueller ordered by Total Marine Fuels Global Solutions (TMFGS) for the French operator CMA CGM. Shell is supporting the orders for two vessels, one of which will supply LNG for cruise ships touring Florida and the Caribbean. Japan’s Kawasaki is capitalizing on its experience with coastguard vehicles to build the country’s first bunker vessel.

LNG carriers

Orders for new carriers continue apace. In October BP ordered six new vessels fitted with a reliquefaction plant allowing evaporated gas to be returned to the tanks as LNG. HHI is building four carriers for Capital Gas Carrier, owned by Greek ship owner Evangelos Marinakis.

A special type of carrier being developed is the ice-breaking LNG carrier. The first of this type is Polaris, built by Arctech Helsinki Shipyard and completed in 2016. It runs on lowsulphur diesel and LNG as fuel to reduce emissions. The ship is also equipped to perform response operations, emergency towing and rescue operations all year round.

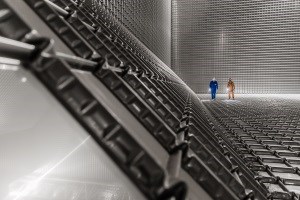

In March 2017 the Russians unveiled the first of 15 LNG ice-breakers for its Yamal project inside the Arctic Circle. The first was christened “Christophe de Margerie” after the late CEO of Total, who died in a plane crash in Moscow in 2014. (Total is co-owner of the project, along with CNCP and the majority shareholder, Novatek.) Built by DSME using an Aker design, the carriers will transport LNG to the European and Asia-Pacific markets. The engines run on LNG and light or heavy fuel oil. The hull is designed to withstand severe ice conditions and is made of E-grade hightensile special steel. Both the Finnish and the Russian vessel use a new propulsion system, the ABB Azipod units, which make the ship easier to maneuver in the ice. Each unit is equipped with a four-blade stainless steel propeller with removable blades. These new types of carrier will make it easier to transport LNG through the Arctic regions. Russia especially will benefit from easier and quicker access to European and Asian-Pacific markets.

Export

Another factor that will ease trading conditions for the LNG sector is the decision by the Panama Canal Authority to remove restrictions on the transport of LNG through the canal. From 1 October 2018 LNG vessels will be able to transit the locks by night, as other types of vessel already do. It will also be possible, for the first time, for two LNG vessels to transit the canal in two different directions on the same day. These measures will greatly aid the US export effort, which will be further boosted by the EU’s desire, expressed by Jean-Claude Juncker, to increase imports from the USA. The USA’s exports are still relatively low (see table) but are increasing rapidly. In March 2018 train 4 of Cheniere’s Sabine Pass liquefaction plant is expected to enter service. Australia has also seen a meteoric rise in its LNG export activities. It currently exports 44.3mn tonnes per year, but this is set to increase sharply in line with Asian demand. The country currently has seven operating LNG developments, with three more under construction, as well as other projects being considered. In October 2017 Chevron’s Wheatstone project shipped its first cargo, and in June 2018 Wheatstone train 2 was started up. On 27 July 2018 the Ichtys project came on line, though full-scale production will take another two years.

Elsewhere in the world, exports are on the rise in Africa and in parts of Asia. In July 2018 Nigeria LNG awarded train 7 of its Bonny Island project to the B7 JV and SCD JV consortia. In April Golar entered into a preliminary agreement to build an FLNG unit to support BP’s offshore operations in Mauritania and Senegal. In the same month Andarko announced it will proceed with a project in Mozambique. Also off Mozambique, Eni’s Coral South project will gain an FLNG built by SOFEC, with a turret mooring system to be supplied by Keppel.

In Papua New Guinea, Exxon Mobil will expand its operations after learning that its P’nyang field is much larger than previously thought. Port Moresby will acquire three more trains, doubling its capacity. In Malaysia, Sapura Energy E&P and its partners Petronas Carigali Sdn Bhd and Sarawak Shell Berhad have made the final decision to develop the Gorek, Larak, and Bakong fields, which will supply gas to the Petronas MLNG complex in Bintulu.

Elsewhere in the world, exports are on the rise in Africa and in parts of Asia. In July 2018 Nigeria LNG awarded train 7 of its Bonny Island project to the B7 JV and SCD JV consortia. In April Golar entered into a preliminary agreement to build an FLNG unit to support BP’s offshore operations in Mauritania and Senegal. In the same month Andarko announced it will proceed with a project in Mozambique. Also off Mozambique, Eni’s Coral South project will gain an FLNG built by SOFEC, with a turret mooring system to be supplied by Keppel.

In Papua New Guinea, Exxon Mobil will expand its operations after learning that its P’nyang field is much larger than previously thought. Port Moresby will acquire three more trains, doubling its capacity. In Malaysia, Sapura Energy E&P and its partners Petronas Carigali Sdn Bhd and Sarawak Shell Berhad have made the final decision to develop the Gorek, Larak, and Bakong fields, which will supply gas to the Petronas MLNG complex in Bintulu.

Import

On the receiving end, facilities for regasification include fixed, on-land facilities and an increasing share of floating regasification and storage units (FRSUs). In Asia the potential for LNG regasification is huge. A newly completed Sinopec-owned terminal at Tianjin, China, has just started importing from Australia. Exxon Mobil is planning Pakistan’s third receiving terminal. Indonesia is planning an import terminal at Bantaeng together with a combined-cycle power plant, and an FSRU is being planned by a JV consisting of Exmar and Humpuss Intermoda Transportasi. In Bangladesh, Summit LNG terminal will build a FSRU at Moheskhali. Japan’s Osaka Gas hopes to build a string of terminals in countries like Indonesia, the Philippines, and Thailand.

Materials

LNG liquefaction, transportation, storage, and regasification are essentiallycryogenic processes normally requiring austenitic stainless steel or nickel steelalloy to safeguard against embrittlement caused by low temperatures and degradation due to wide temperature fluctuations. Types 304(L), 316 (L), Invar® (36% nickel steel), 9% nickel steel, and (more recently) 7% nickel steel are all grades being commonly applied.

To these we must now add a high manganese steel developed by POSCO. As tough as 9% Ni steel, this alloy is designed for use in the cargo tanks, fuel tanks and piping systems of LNG carriers and LNG-fuelled ships. As well as having high tensile strength and elongation and a small thermal expansion coefficient, the alloy contains no nickel, so provides a welcome alternative in cases where nickel availability is limited. POSCO has said that the product is 20-30% cheaper than Ni alloy steel, stainless steel or aluminium alloy. The new material was used in the construction of a dualfuel bulk carrier, the Green Iris, which entered service in February 2018 and is operated by Ilshin Shipping. Mn steel is used in the IMO type-C LNG fuel pressure tank, which has a capacity of 500 cubic metres and located on the aft mooring deck. This ship is used to transfer limestone between two harbours in South Korea, but its acceptance internationally is only a matter of time after it received ASTM approval in May 2017.

To these we must now add a high manganese steel developed by POSCO. As tough as 9% Ni steel, this alloy is designed for use in the cargo tanks, fuel tanks and piping systems of LNG carriers and LNG-fuelled ships. As well as having high tensile strength and elongation and a small thermal expansion coefficient, the alloy contains no nickel, so provides a welcome alternative in cases where nickel availability is limited. POSCO has said that the product is 20-30% cheaper than Ni alloy steel, stainless steel or aluminium alloy. The new material was used in the construction of a dualfuel bulk carrier, the Green Iris, which entered service in February 2018 and is operated by Ilshin Shipping. Mn steel is used in the IMO type-C LNG fuel pressure tank, which has a capacity of 500 cubic metres and located on the aft mooring deck. This ship is used to transfer limestone between two harbours in South Korea, but its acceptance internationally is only a matter of time after it received ASTM approval in May 2017.

References

(1) https://www.energydigital.com/top10/top-10-largest-exporters-liquidnatural-gas, dated 19 April 2018.

Did you know?

– Last year, a Russian ice-breaking LNG carrier, the Christophe de Margerie, sailed across the Arctic from Norway to South Korea in 19 days, about 30% quicker than the regular route through the Suez Canal.

– Australia, the world’s second-largest LNG exporter, faces an energy shortage! LNG export has been promoted so massively that some parts of the country are running short of gas. An import terminal is therefore planned at Port Kembla on the east coast, and Venice Energy is to submit proposals for floating regasification unit Port Adelaide in the south