Researchers at Oak Ridge National Laboratory (ORNL), Tennessee, USA, and the US National Energy Technology Laboratory (NETL), have developed and additively manufactured a light, crack-free alloy capable of operating at temperatures above 1,316°C (2,400°F) without melting.

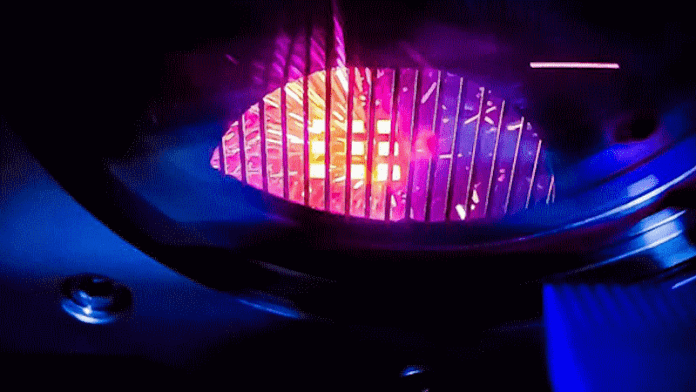

The alloy combines seven elements in a niobium-rich, complex concentrated alloy whose melting point is at least 48% higher than the nickel and cobalt superalloys previously developed by ORNL. Researchers fine-tuned the electron beam melting process to additively manufacture test parts from the novel alloy.

The new alloy’s light weight and ability to withstand such high temperatures could enable additively manufactured turbine blades to better handle extreme temperatures, reducing the carbon footprint of gas turbine engines like those found in airplanes.