Maritime and offshore industry spare parts will now be delivered more efficiently through new technology. Saving cost and time, the use of additive manufacturing or 3D printing brings a whole new way of ensuring operations keep momentum up and waiting times at a minimum.

Text & images by Pelagus 3D

thyssenkrupp and Wilhelmsen have launched a joint venture company, Pelagus 3D, into global maritime and offshore services market.

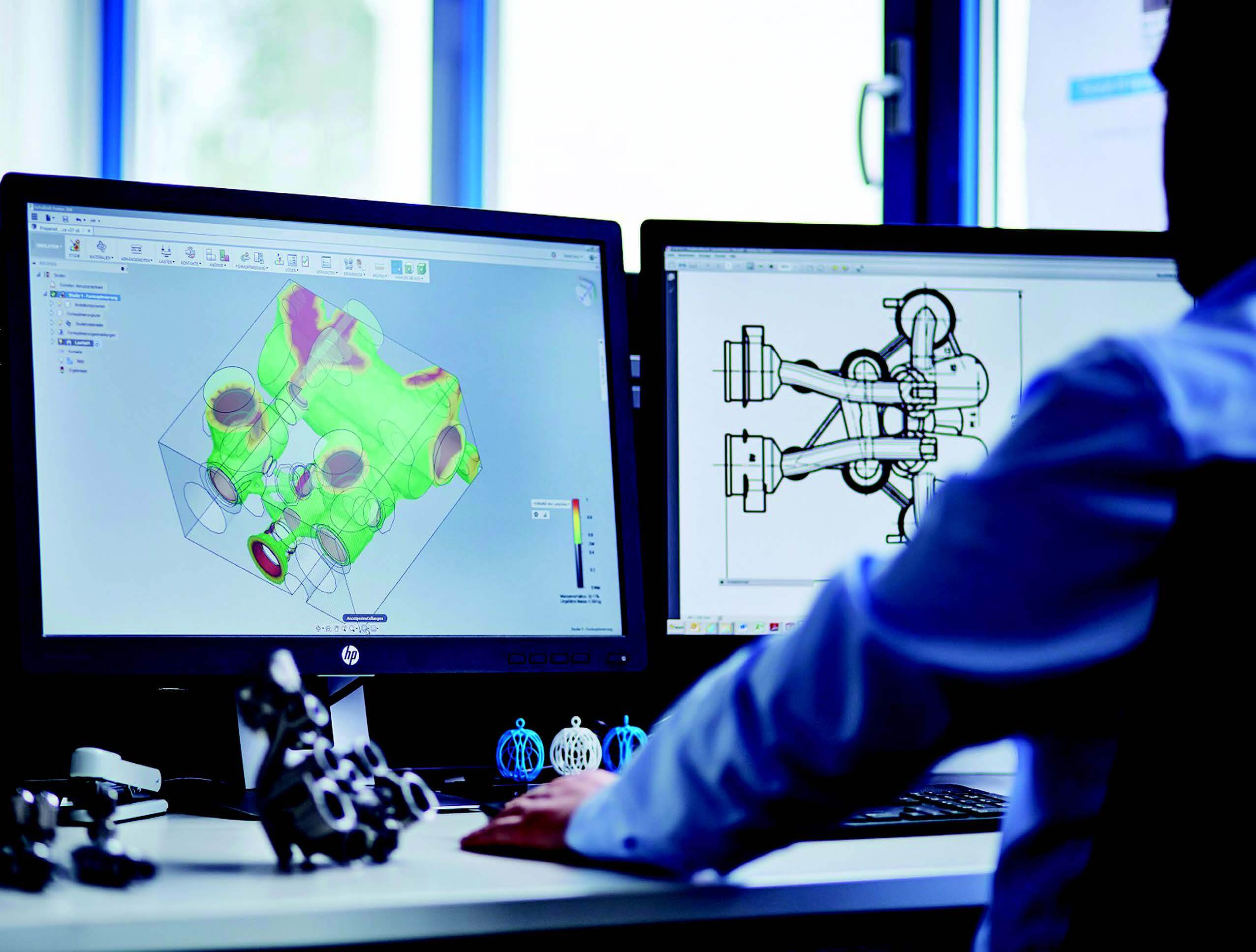

Pelagus 3D envisions to be the largest one-stop, on-demand digital manufacturing partner for the maritime and offshore industries. It uses Additive Manufacturing (AM) to deliver maritime spare parts more efficiently in terms of time and cost, allowing customers to ensure their vessels’ seaworthiness and keep their operations moving on schedule. The company produces AM parts in a wide range of materials, including nickel alloys, titanium, steel, cobalt chrome, copper, refractory metals and aluminium.

Strong industry owners

The new company brings with it the storied history and capabilities of its founders. thyssenkrupp contributes its technological expertise in additive manufacturing as well as capabilities from its own Tech Centers in Singapore and Germany to supply 3D metal products for application in shipping and other industries. thyssenkrupp Materials Services, the company’s materials distribution and service provider, further adds deep knowledge in the development of digital supply chain solutions and platforms.

Wilhelmsen brings its in-depth maritime expertise and direct ongoing experience in understanding the needs of vessel fleet managers, supporting the delivery of a wide portfolio of maritime products and services for more than half of the global merchant fleet.

Highly secure platform

Pelagus 3D hosts a highly secure digital platform that serves as the main connection between customers such as vessel managers and Original Equipment Manufacturers (OEMs). As a one-stop platform for maritime and offshore spare parts, Pelagus 3D has access to the different printing technologies used by its network of partners around the world, allowing Pelagus 3D to respond to requests to print any material. Bringing together highly specialised engineering capabilities as well as a strong maritime and offshore network, Pelagus 3D elevates this digital storefront for customers, ensuring that this ecosystem can deliver their needs more cost efficiently and in a timely manner.

thyssenkrupp and Wilhelmsen will have equal ownership of Pelagus, with both companies having 50% stake in the newly formed company. Its Board of Directors consists of industry leaders who bring invaluable skills and experience to aid the company in navigating challenges and opportunities ahead.

Pivotal industry entry

The debut of Pelagus 3D will help usher in the acceleration of the adoption of AM technologies, which will guide further growth for the industry.

“Beyond addressing perennial pain points in the maritime and offshore sectors such as obsolescence and long lead-times for mission-critical parts with on-demand production, Pelagus 3D is well positioned to address similar needs in other industry sectors, improving customer experience with added supply chain resilience, lowering material waste and inventory cost, contributing to environmental and sustainability goals,” added Dr Ho, Chief Executive Officer, National Additive Manufacturing Innovation Cluster (NAMIC).

The entry of Pelagus 3D also underscores the positive steps the maritime industry has been making towards digital transformation. Singapore, for example, leverages technology to enhance the sector’s operations such as establishing a digital clearing process and port systems.

“In the maritime sector, AM can help unlock tremendous efficiency potentials with its fast and low-volume high-value fabrication capability of equipment component parts on-demand. This agility ensures responsive support to meet the needs of ships and ports for urgent and critical spares. MPA welcomes the establishment of Pelagus 3D in Singapore and the business opportunities it will bring along, including new and exciting jobs.”, said Kenneth Lim, Assistant Chief Executive (Industry & Transformation), Maritime and Port Authority of Singapore.

About this Tech Article

This tech article appeared in Stainless Steel World, December 2023 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format) – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.