Outokumpu, a pioneer in sustainable stainless steel, and ON2Quest, an innovator in the field of industrial gas purification and generation, are piloting a cutting-edge gas recovery system that will enable the recovery of hydrogen from their production processes. This collaboration aims to enhance sustainable operational efficiency by integrating hydrogen recovery into the stainless steel production cycle at Outokumpu’s production plant in Krefeld, Germany.

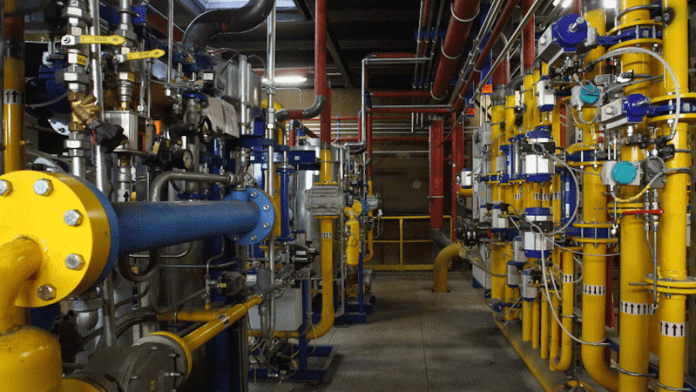

The gas recovery system is designed and engineered according to the requirements of Outokumpu to recover hydrogen, where the gas will undergo a rigorous cleaning and compression process to ensure that it will be suitable for use again. The purified hydrogen will then be blended with natural gas, creating a hybrid fuel that will be used to power the burners. This innovative approach not only reduces waste and optimises resource utilisation but also supports their ecological commitment by lowering carbon emissions associated with the production processes.