Okuma’s high-performance solutions take the cutting performance of its powerful machines to a new level and enable complete machine processes with advanced technologies.

Turn-Cut makes it possible to map a turning process onto machining centers or multitasking machines.

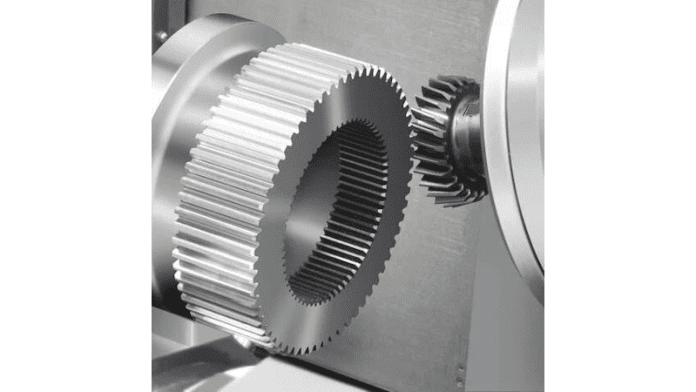

Okuma’s Gear Machining Package is a hardware and software add-on for turning and milling centers that simplifies gear programming and cutting by selecting the tool type, workpiece data and machining parameters. Multiple spindles are automatically synchronized, reducing machining times. Both hobbing and skiving processes are supported.

The Hyper-Surface feature is not only important for tool and die construction. It detects changes in programmed shapes and ensures a consistent feed rate. This improves surface quality and reduces machining time.

When machining demanding and difficult-to-cut materials, such as Inconel, Dynamic Tool Load Control is an advantage. The application measures the concentricity and position of each cutting edge of an insert cutter and adjusts the feed rate for each cutting edge separately. This method loads the cutting edges evenly and compensates for concentricity problems. This ensures consistent and reliable machining, extends tool life, reduces downtime and lowers production costs.