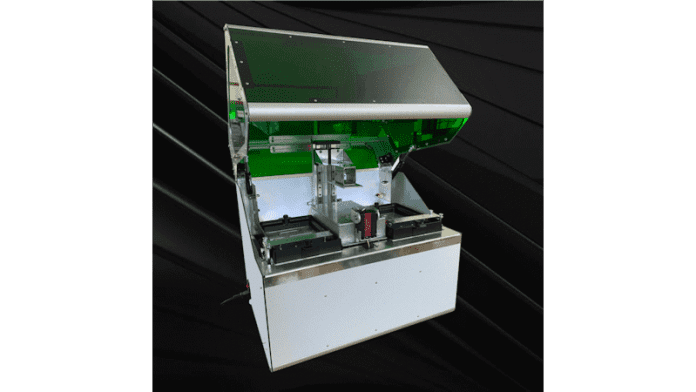

MAASS, a new stereolithography technology developer, has launched its inaugural system, the Shimmy MMSLA (Multi-Material Stereolithography) 3D printer – marking the team’s transition from internal development to a commercial product.

MMSLA introduces several technological innovations that address long-standing challenges in AM, including a dual-vat system enabling simultaneous printing of two distinct materials; resolution capabilities ranging from 0.5 to 50 microns; an integrated cleaning system that prevents cross-contamination between materials; support for high-conductivity and dissolvable support materials; and a build volume of 78 mm x 51 mm x 141 mm optimized for R&D applications.

The system’s capabilities make it particularly valuable for several emerging applications, including 3D printed electronics with 2-mil (50 microns) conductive traces; complex non-planar circuit designs; dissolvable support structures for ultra-high-quality surface finishes; research and development of smart materials; and rapid prototyping of multi-functional devices.

MAASS’s technology platform is designed to scale for future manufacturing applications. The company’s roadmap includes developing higher-throughput systems based on the same core technology for mass production of multi-material parts.