Photos: City of Melbourne

Street furniture defines a city’s urban landscape, and stainless steel is becoming a material of choice for its long-term cost benefits in addition to its sleek designs, durability, and visual appeal.

In Australia, the City of Melbourne has led the way in sustainable materials selection, undertaking a life cycle costing comparison study over a 25-year term between carbon steel and stainless steel for use in its public street furniture.

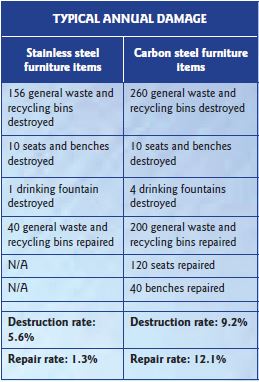

The products studied and manufactured included 1200 general waste bins, 500 recycling bins, 800 seats, 400 benches and 80 drinking fountains. Two broad costing components were considered:

- The initial (procurement) cost of the different products in the two materials.

- The ongoing maintenance costs, including costs associated with the following:

- Items physically destroyed when in situ and in service.

- Repairable damage to items when in situ and in service, e.g., graffiti.

- Any required repairs due to natural corrosion and degradation.

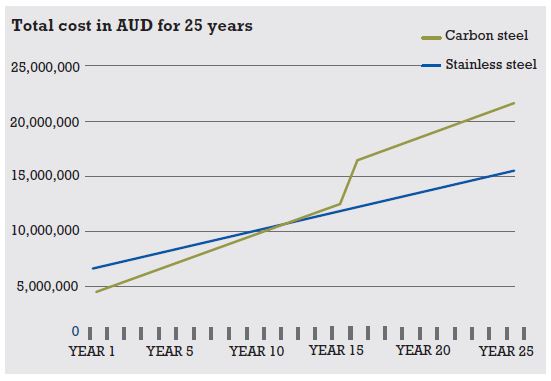

The total cost of products made from carbon steel was AUD 21.1 million:

- AUD 4 million in procurement costs.

- AUD 4 million in early replacement (re-procurement) costs.

- AUD 600,000 in maintenance costs (i.e., graffiti removal and re-coating of surfaces) per year.

The total cost of products made from stainless steel was AUD 14.8 million:

- AUD 6.2 million in procurement costs.

- AUD 400,000 in maintenance costs per year.

Choose stainless steel

Stainless steel street furniture products realised a financial saving of AUD 6.2 million over a 25-year term or AUD 250,000 per year when compared with carbon steel. The stainless steel products are expected to last much longer than 25 years, delivering further cost savings for the City of Melbourne. While there may be a higher capital cost initially, the benefits of using stainless steel are unmatched in its material performance and reduction in ongoing maintenance and life-cycle costs.

This article was adapted and originally published by World Stainless: www.worldstainless.org. Kindly republished with permission of the Australian Stainless Steel Development Association (ASSDA), a non-profit industry group that has been developing a strong and vibrant stainless steel industry in Australia since 1992. For information, visit www.assda.asn.au

About this Featured Story

This Featured Story appeared in Stainless Steel World June 2023 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.