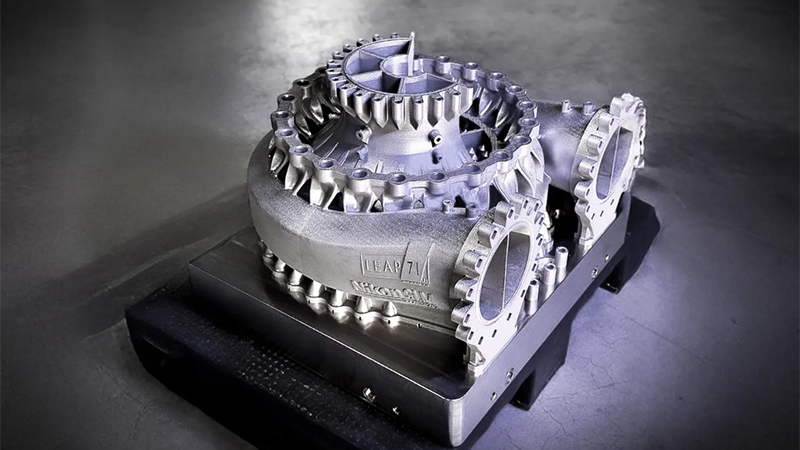

LEAP 71 has announced the successful production of a 2000 kN (2 Meganewton) full-flow staged combustion rocket engine injector head with German/Japanese industrial 3D printing pioneer Nikon SLM Solutions.

The component is a critical element of the LEAP 71 XRB-2E6 methane/liquid oxygen rocket engine. At 600 mm in diameter, the object is one of the major and most complex 3D-printed spacecraft parts ever produced. It was generated entirely by LEAP 71’s Noyron Large Computational Engineering Model, a physics-driven software system described as “the first AI that builds machines,” operating entirely without human intervention.

Nikon SLM Solutions printed the part from Inconel 718, an aerospace-grade nickel alloy specially designed to withstand the enormous heat loads and pressures of a full-flow staged combustion (FFSC) engine cycle.

At 2 Meganewton, the XRB-2E6 targets a similar thrust level to the engines currently powering the world’s latest generation of heavy-lift launchers. The company aims for practical testing of the XRB-2E6 in Q4 2027. As part of the aggressive schedule, LEAP 71 is forging partnerships for early validation of the industrial processes needed to reliably manufacture the engine, using some of the major metal 3D printers in the world.