The metal industry, especially the steel industry, faces challenges regarding delivery time, production costs and product quality driven by high requirements from, e.g. the automotive industry. One measure to address these challenges is production automation with a comprehensive understanding of material behaviour under certain control actions in the rolling production lines of long products.

Johann Peters, LAP GmbH Laser Applikationen, Germany

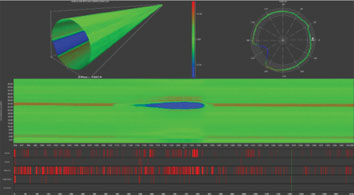

Contactless inline measuring systems play a key role in production optimization. Laser-based systems are the solution for sound information about the product geometry and its surface condition with high accuracy. The detection of deviations of profile and surface, as well as the analysis of its source regarding the caliber is crucial for taking the right control actions in the rolling line. Smart evaluation and data processing allow real time detection of product parameters and the supply of significant details for the process control system and the operator, respectively.