The supply chain crisis has made it difficult for the aerospace industry to get their hands on investment cast parts. 3DEO offers an alternative.

Text and images by 3DEO

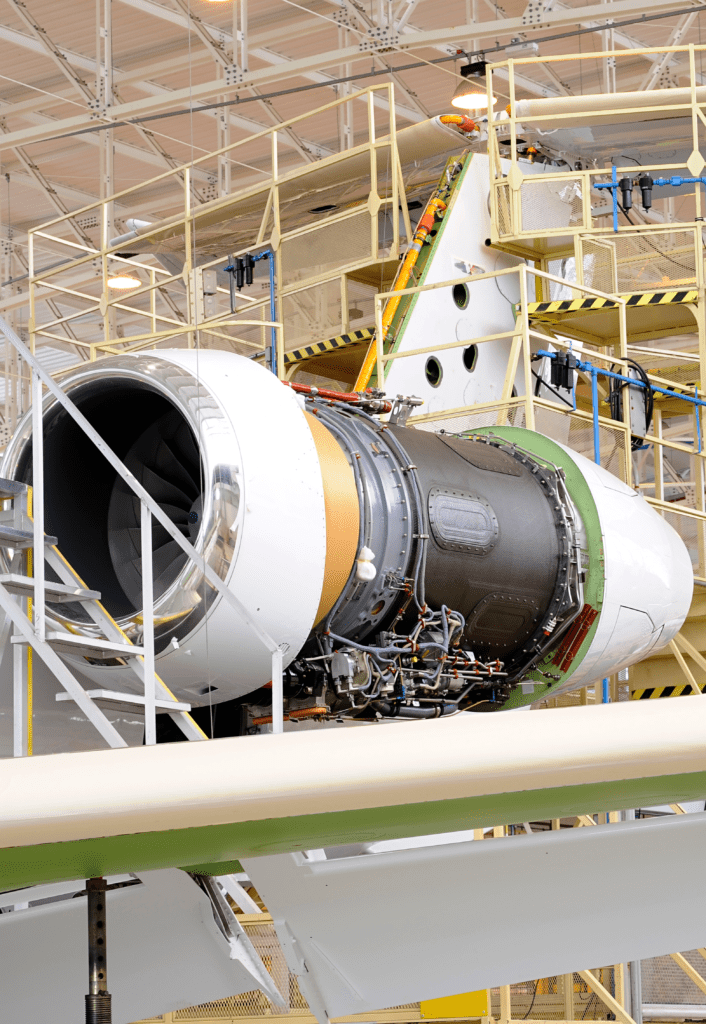

As those who use investment cast parts in their products for the aerospace industry know, casting has always presented challenges: dimensional variation, post processing steps, non-destructive testing requirements, and uncertainty in material properties. For many, the final straw was the recent supply chain crisis that brought casting-centric production lines to a halt.

When it comes to casting, the selection of high-quality domestic providers is shrinking as experts with relevant expertise retire. Meanwhile, supply chains continue to struggle due a variety of causes. This is forcing many in the aerospace industry to take steps to address the uncertainty and significant delays they’re experiencing with cast parts: it’s making it difficult to keep promises to customers.

Even when parts are delivered on time, the value is just not as compelling as it used to be due to rising adjacent costs. When considering the total cost of the manufacturing process— including the aforementioned required secondary operations, carrying costs and delays from overseas suppliers, NDT fallout due to poor quality, necessary rework, and line downtime—then casting is not the great deal the piece price quote alone would lead you to believe. Poor quality poses downstream uncertainty and reputational risk for your company, and many are finding that cast parts end up costing much more than they bargained (and budgeted) for.

Throughout the COVID-19 pandemic, 3DEO has heard from multiple customers about their intensifying challenges with investment casting, and they’ve learned a great deal about where they are able to help their customers. This article highlights a few components they’ve produced hand-in-hand with their aerospace customers to get parts flying off their lines again.

Note: This case study is based on a US-based Tier 2 aerospace supplier’s success in migrating from a legacy investment cast supply chain to 3DEO’s metal 3D printing services.

The challenge

The challenges associated with this component are a combination of failings of the supply chain and fundamental limitations of the investment casting process.

The customer, an aerospace tier 2 supplier, was unable to deliver subassemblies to their customer because their supplier was months behind schedule. The casting supplier saw this order as a relatively small proportion of their revenue for difficult-to-produce parts, and consequently had deprioritized them. The tier 2 supplier could not get commitments from their supplier to tighten delivery timelines, let alone ship parts.

Ultimately, the final customer, the aircraft manufacturer, was left in a challenging position sitting on over USD 12 million of incomplete product, awaiting subassemblies from the tier 2 supplier. In addition to suppliers missing delivery timelines, a systemic challenge for this aerospace company was the poor quality of the investment cast parts themselves. According to this customer, the cast parts they receive from their vendors struggle with porosity.

This problem is not predictable—until the parts are radiographically or ultrasonically inspected, there’s no way to ensure casting quality. For instance, this manufacturer received a shipment of castings which nearly all failed NDT inspection, requiring rework. It was a lucky close call that they could even rework the components, as they previously had a failed run in 2019 that had to be scrapped entirely.

“We sectioned the samples you’ve provided and reviewed them side-by-side with the cast version of the same part; the castings look like Swiss cheese by comparison,” stated the Engineering Manager of the aerospace customer.

While it would take time to execute, as a result of all these headaches, the Director of Engineering for the product group that they had been working with actively worked to migrate parts away from casting to more reliable and timely firms that are using technologies that produce higher performing, more predictable parts. They tapped 3DEO to be just such a supplier.

The solution

3DEO was able to help this customer solve its challenges with this part and get their subassemblies back in production—which was the beginning of a true partnership. This customer leveraged 3DEO’s resources in a way that created long-term competitive advantage for the aerospace company, as they continue to bring additional components to be adapted from investment casting to additive manufacturing at scale. But what got the ball rolling?

To get started, 3DEO’s applications engineering team met with the customer’s engineering and procurement teams to fully understand the application in question and ensure 3DEO can deliver a working solution.

To get started, 3DEO’s applications engineering team met with the customer’s engineering and procurement teams to fully understand the application in question and ensure 3DEO can deliver a working solution.

After reviewing the drawings and CAD designs, 3DEO immediately went to work on the first articles. Using its proprietary technology, they optimized the customer’s design for additive manufacturing in an effort to deliver a part closer to the final shape and eliminate post processing.

First articles were delivered in two weeks. One of the main advantages is that the sample parts are made on the same printers that produce production parts. As a result, any testing done on first articles remains valid for initial production runs. This dramatically accelerates launch cycles for new components.

Quality testing revealed that the material properties, dimensional tolerances, and surface finish were superior to investment casting. Given the situation with the complete lack of parts from the investment casting supplier, the aerospace customer was able to seamlessly transition production to 3DEO.

About 3DEO

3DEO is a manufacturer of 3D-printed precision metal components made with its patented metal 3D printing technology: Intelligent Layering®. They created the Manufacturing Cloud™, an end-to-end manufacturing platform built to scale 3DEO’s proprietary metal 3D printers into mass production through software, 3D printing, robotics, automation, augmented reality, and materials innovation. 3DEO is ISO 9001:2015 certified.

About this Featured Story

This Featured Story appeared in Stainless Steel World May 2023 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.