Hybrid CNC Parts has expanded its advanced manufacturing capabilities with the acquisition of two additional Phillips Additive Hybrid Laser-Wire systems, powered by Haas and Meltio. This investment triples the company’s hybrid manufacturing capacity, providing customers with increased flexibility, redundancy, and throughput for precision metal additive and subtractive manufacturing within a single facility.

The new systems enhance the company’s support for industries such as aerospace, defense, and advanced R&D—sectors that require rapid prototyping, component repair, and small-batch production of complex metal parts. These applications often involve high-performance materials such as nickel- and cobalt-based superalloys, including Inconel® and Stellite®, as well as various tool steels.

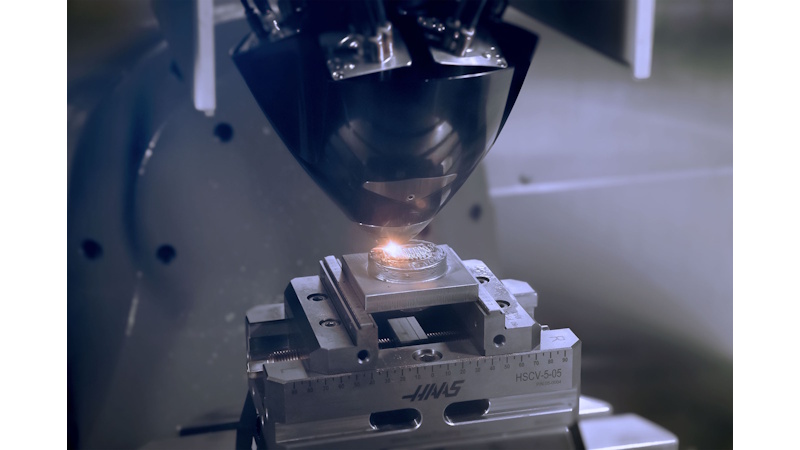

With the addition of the two Phillips Additive Hybrid systems, Hybrid CNC Parts now operates three Laser-Wire Hybrid units. The fleet showcases Meltio’s IR laser additive technology integrated into two Haas VF-5 machines and a UMC-750, increasing production capacity, improving system redundancy, reducing downtime, and enabling parallel manufacturing and development workflows.