By Patrik Kolmodin, Product Line Manager Agitators, Sulzer

PhosAgro is the biggest manufacturer of phosphate-based fertilizers in Europe.

The largest site is the chemical cluster in Cherepovets, Russia, where sulphuric acid is produced locally from elementary sulphur.

Two new sulphur melters were added to the PhosAgro plant during a recent expansion project. It was essential to use agitators to manage heat transfer in the melters to ensure the plant’s capacity.

The challenge

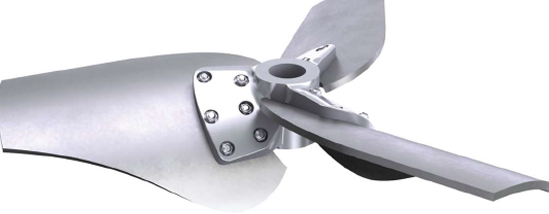

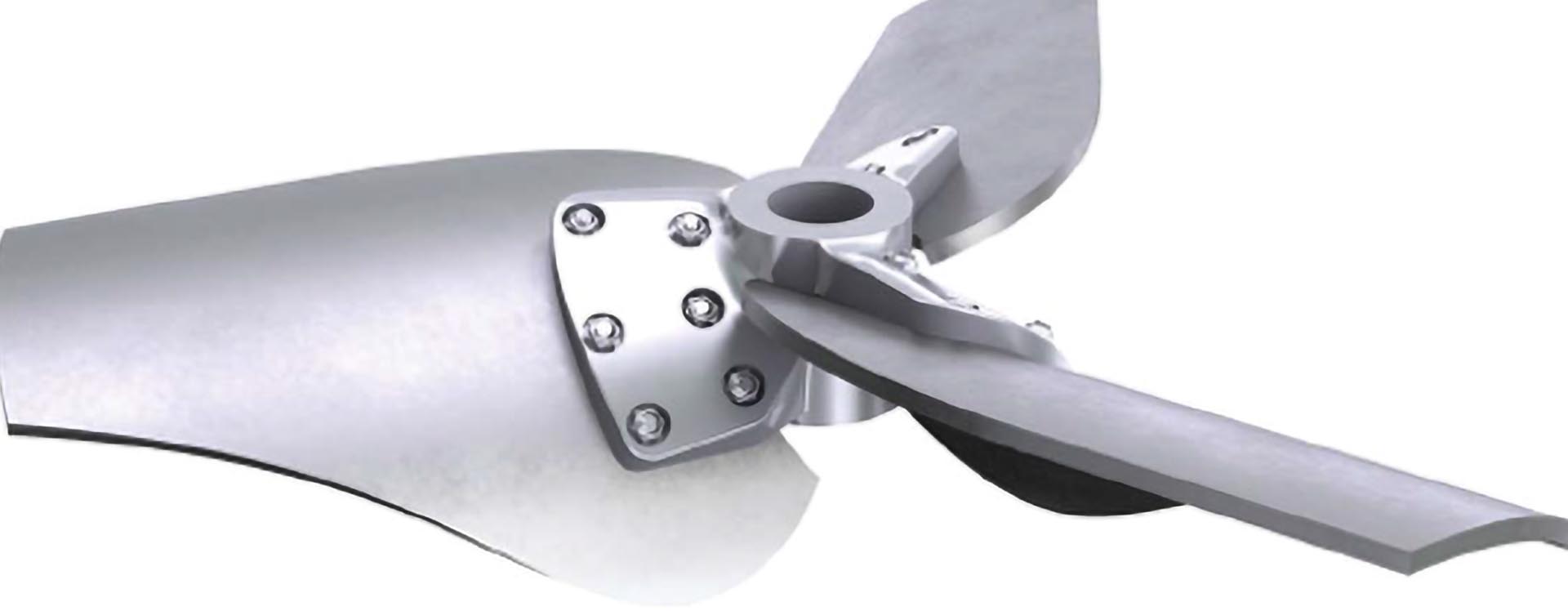

Both melters were designed with six steam heating coils, and heat transfer was essential to achieve the required melting capacity. The design temperature for the melted sulphur was 130°C. A proposed agitator had a 200 kW motor with three impellers, where the lower one was a pitch blade turbine.

The main challenges were:

■ High heat transfer requirement

■ Heavy-duty application

■ Corrosive environment in the gas phase

■ Large ambient temperature range between -47°C and +40°C