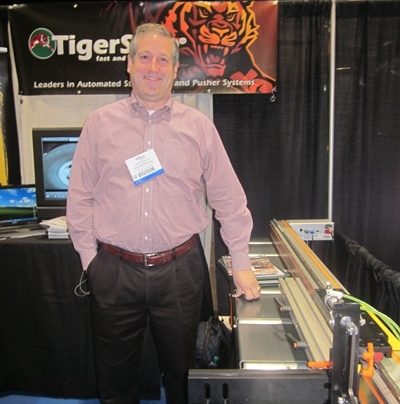

TigerStop’s new Vice President of Sales and Service, Jack Ragan, spoke with Stainless Steel World Americas about his new role, the idea behind the TigerStop, and their new feature, the TigerGripper.

Can you tell me a bit about TigerStop?

What is the TigerStop?

The TigerStop is a beam with a belt that runs inside, with a positioner, a controller, the electronics and the motor. Instead of measuring the parts, and adjusting the position to stop manually, the operator who’s running the bandsaw for example, can just go to the controller, type in what he wants and this unit will ensure that the material is cut accurately. You can also take a long piece of material, say 10m long or longer, that you need to make 6 cuts of 500ml, and 10 cuts of 1m or whatever it may be, and program it, so as it makes those cuts, the positioner moves farther and farther from the machine, and when it is completed, it retracts back and starts the process over again. The TigerStop is our basic machine, and we’ve expanded that to our TigerRack which is the next step up. Now we also have a new feature, our TigerGripper; this operates to grab pipe or tube and move that frontwards and backwards into any of the machines I described. We build the machine based on the application, factoring in material type, weight, length and the specific machine it will be linked to. Our machines might be as small as 6 to 8ft or it could be 100ft or more long. For us, it doesn’t matter what material you’re working with, our product can be used on anything and that’s really where we fit in. We’re adding this device onto dozens and dozens of different types of machines.

Are you looking to target a certain market?

We target every market, but we’re really putting a lot of emphasis on the metal market as a whole. There is a lot of new development with our metal products, but we also focus on job shops, window and doors for commercial applications, storefronts etc.

What does being the Vice President of Sales and Service involve?

We have three regional sales managers in the U.S. and Canadian market; I work with them to develop our plan for our distribution channels, how we are going to market, and negotiating with our customers. On the service side, I’m responsible for managing the service technicians and making sure we’re delivering the proper service to our customers. What’s nice about TigerStop is that we are a relatively small company; we have the two owners of the company, we have our engineering department, R & D department, production and sales all out of one office. So there is a lot of interaction and collaboration between engineering and sales, service and production etc. We really try and stay involved with what we think the market needs.

What attracted you to this particular position?

I was in the machinery business for about 18 years; I worked for another manufacturer on the wood side. TigerStop offers American-made products that are innovative, it’s a real leader in our market, and it presented a new opportunity for me. I was a regional sales manager, a road warrior for all those years, and I was given an opportunity to move into management and become more involved in the day in and day out business. I also got to know the owners of the company over the last 7 or 8 years because they live in Portland as well. I had a really great feeling about the product, their commitment to innovation and their commitment to service.

What do you particularly enjoy about your work?

I think the best part is working with our customers to develop solutions to their headaches. Every customer is different, and every application and issue is different, which makes it interesting. We’re really trying to focus on main manufacturing, reducing waste, reducing waste labor, delivering on time and helping our customers be innovative and stay competitive. As an American-made product, we really care about manufacturing being kept in the United States, that expands to Canada as well as they are a very important partner to us, we have a lot of distributors and customers in Canada. Keeping the manufacturing of our products local is important because if we are supporting manufacturers then we are supporting ourselves; that’s something that from the top of the company down is really near and dear to our hearts.

You have a large customer base in Canada, where are the rest of your clients located?

I would say most of our customer base is in the U.S. followed by Canada, but right now we’re exporting products to China, New Zealand, Australia, Mexico, and the Caribbean. Our sister factory in the Netherlands is catering to all of Western Europe, expanding into Russia, Eastern Europe as well.