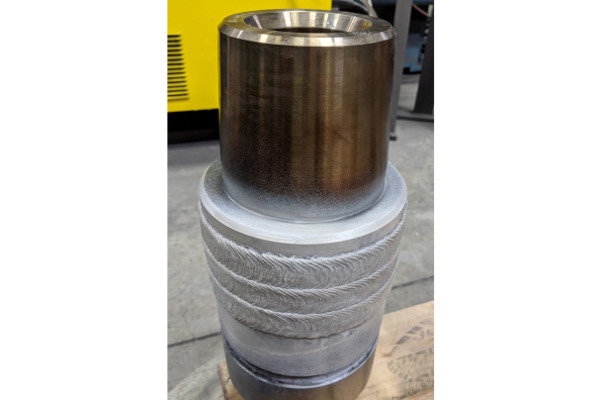

Stoody®, an ESAB brand, announced that Stoody HB-64 cored wire has been awarded Fearnley Procter NS-1 Level 2 certification for oil field hardbanding application and reapplication. Stoody HB-64 (60 to 64 Rockwell C hardness) is a tool steel alloy enhanced with niobium carbide for superior performance and crack-free harbanding.

Its specially formulated wear-resistant alloy composition produces a uniform distribution of small primary metal carbides in a martensitic matrix. Stoody HB-64 provides a weld deposit with a low coefficient of friction to reduce tool joint and casing wear. It shows excellent abrasion resistance under hardbanding conditions. Stoody HB-64 is approved under NS-1 for new hardbanding applications as well as for reapplication onto itself.

Stoody HB-64 cored wire is available to any customer worldwide and is sold in a 33-lb. (15-kg) wire basket or a 50-lb. (22.7-kg) moisture protected Poly Pak, both in 1/16-in. (1.6 mm) diameter.

The Fearnley Procter NS-1 accreditation program provides oilfield equipment and service companies with an industry-recognized approval program that supplements the requirements of American Petroleum Institute (API) standards and demonstrates superior quality management and performance to offshore and onshore operators.