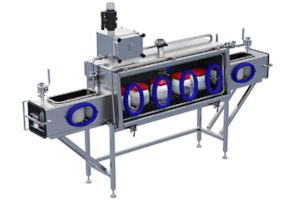

Custom Powder Systems has introduced the Metal Powder Packaging System, designed to address the specific challenges of dispensing and packaging large quantities of metal powders. With its advanced features, it aims to improve packing efficiency in the Additive Manufacturing industry.

The design prioritises safety by incorporating a vacuum exhaust filtering system to maintain a clean and controlled environment during the packaging process. A lift-up gull wing door design provides easy access. Moreover, in-and out-feed airlocks actively prevent cross-contamination, whilst a manually controlled inert environment helps to preserve product quality.

The Metal Powder Packaging System offers the following features as upgrades: 316L stainless steel construction; automated lidding systems, bottle filling and bottle indexing; bottle clamp for securing lid; bottle labelling systems; custom sizes; drum dispensing through floor; fugitive dust collection systems; humidity monitoring; IBC charging system; internal accessory ports (for additional equipment); O2 monitoring; PLC environmental controls; polished welds; and UL certified panel.