The US Navy Small Business Innovation Research (SBIR) has awarded QuesTek Innovations a contract for the development of a digital toolkit that predicts the life of components affected by corrosion, pitting, and fatigue.

By Joanne McIntyre

The contract was awarded to US company QuesTek, a pioneer in Integrated Computational Materials Engineering (ICME) which leverages technologies to reduce the materials development time and cost, while increasing the performance of novel materials. This award underscores both the critical importance of addressing corrosion fatigue in naval aerospace systems and the company’s long-standing leadership in solving complex materials challenges with physics-based design approaches.

Predicting corrosion accurately

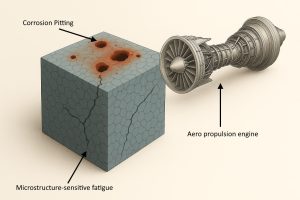

Corrosion fatigue is one of the most persistent and costly degradation mechanisms in defence and commercial aerospace. For the US Navy, corrosion alone contributes to an estimated USD3 to USD4 billion in annual sustainment costs, while fatigue accounts for more than half of aircraft component failures. When these two mechanisms act together, they create a destructive feedback loop – where corrosion accelerates fatigue crack initiation and growth, and cyclic loading destabilises protective films, deepening corrosion damage.

Despite its widespread impact, corrosion fatigue remains difficult to predict accurately. Traditional empirical models, based on historical testing, struggle to account for the wide variability in materials, loading conditions, environments, and manufacturing processes. The result is often costly overdesign, excessive inspection requirements, and the risk of unexpected failures.

Despite its widespread impact, corrosion fatigue remains difficult to predict accurately. Traditional empirical models, based on historical testing, struggle to account for the wide variability in materials, loading conditions, environments, and manufacturing processes. The result is often costly overdesign, excessive inspection requirements, and the risk of unexpected failures.

QuesTek is addressing this challenge with its Materials by Design® methodology, which applies the principles of Integrated Computational Materials Engineering (ICME). The physics-based, multiscale modelling approach links processing, structure, properties, and performance to enable accurate, mechanism-informed predictions. As the company has worked with the Department of Defence, Department of Energy, and other federal agencies for twenty-five years, it has a good understanding of the demanding environments and performance expectations of mission-critical systems and has worked to deliver materials and design solutions that meet or exceed them.

Mechanistic & microstructure sensitive

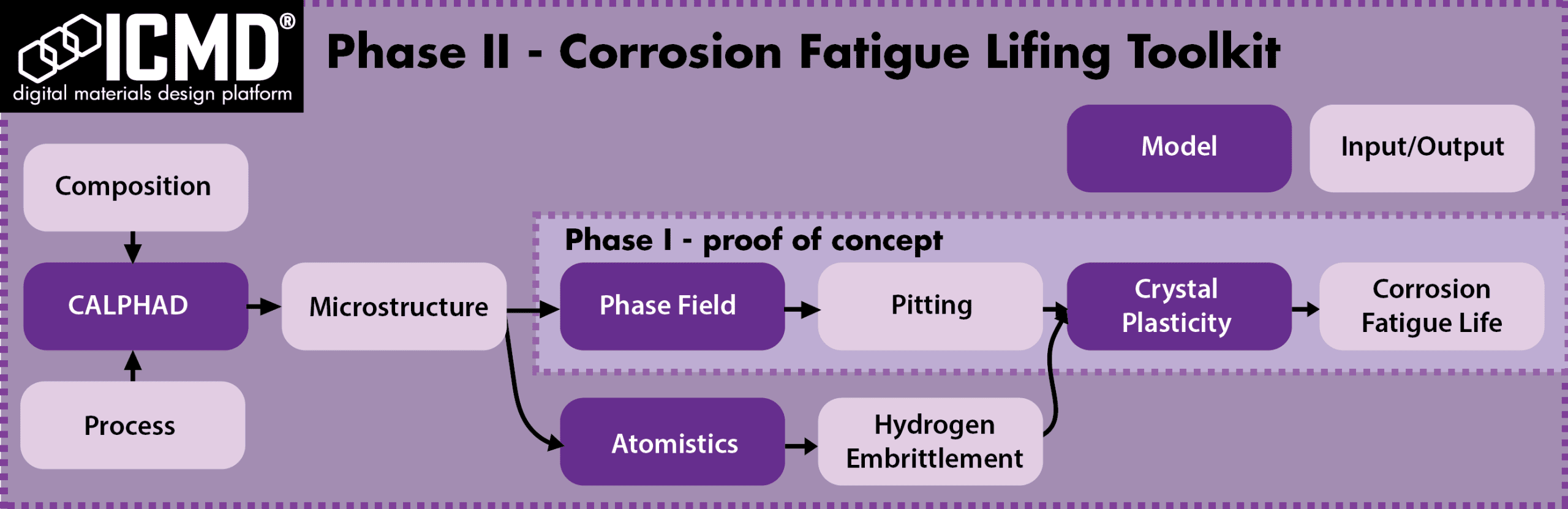

For this SBIR project, the company is developing a mechanistic, microstructure-sensitive corrosion fatigue lifing toolkit that integrates several state-of-the-art modelling methods, including:

- CALPHAD modelling for microstructure and phase prediction

- Phase field modelling for corrosion and pitting behaviour

- Atomistic modelling to capture hydrogen embrittlement and stress corrosion cracking

- Crystal plasticity finite element modelling (CPFEM) for fatigue response prediction based on microstructure

Accelerating innovation

QuesTek is partnering with Prof. Zachary Harris of the University of Pittsburgh on this initiative. Prof. Harris is a leading researcher in the fatigue and fracture behaviour of structural materials exposed to aggressive environments. His laboratory will lead the experimental component of the project, including material procurement, high-resolution microstructural characterisation, mechanical testing, and fractographic evaluation. These validation datasets will directly inform and calibrate the predictive models within the platform.

The benefits of this framework extend well beyond defence. Corrosion fatigue is a universal issue across aerospace, automotive, energy, and heavy industrial sectors. By expanding its ICMD® platform to account for corrosion, pitting, and hydrogen effects, QuesTek aims to empower commercial OEMs and suppliers to optimise durability, reduce costs, and accelerate innovation.

About this Tech Article

Appearing in the August 2025 issue of Stainless Steel World Magazine, this technical article is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new technical articles with our Stainless Steel community. Join us and let’s share your technical articles on Stainless Steel World online and in print.