Additive manufacturing using a laser-based directed energy deposition process.

This year we are proud to present a series on additive manufacturing which has been written exclusively for Stainless Steel World by additive manufacturing expert Dr Todd Palmer from Pennsylvania State University. In this first article, Dr Palmer provides an introduction to the subject.

By T.A. Palmer (a,b, a) Department of Materials Science and Engineering and (b) Department of Engineering Science and Mechanics, The Pennsylvania State University, USA

The use of additively manufactured austenitic, duplex, and precipitation hardenable martensitic grade stainless steels in critical applications is limited by large uncertainties in material properties and performance. This uncertainty can be traced to complex and unique microstructures driven by processing conditions significantly different than those used to produce their wrought counterparts. Accelerating the implementation of additively manufactured stainless steels will require the development of science-based specifications and standards supported by fundamental physical metallurgy, powder processing, and welding science.

What is additive manufacturing?

Additive Manufacturing (AM) or 3D printing encompasses a range of processes focused on the layer-by-layer fabrication of complex geometries not possible through traditional subtractive machining processes. It has been widely touted as being the “next Industrial Revolution”[1] and “…poised to transform the industrial economy”[2] by prognosticators and technology evangelists. Even though it is widely hailed as a new and revolutionary technology, AM has slowly developed over the past 40 years for a range of materials systems. Stainless steels have been a major player in this evolving story and will continue to be. Before addressing this important alloy system, however, a brief exploration of the history and underlying characteristics of AM processing is required.

For plastic and polymer materials, most of the machines and processes that are currently available grew from early work in the 1970s and 1980s on rapid prototyping. These processes were primarily directed at accelerating the design process and form the basis of what the public primarily views as 3D printing. Soon after the introduction of these plastic and polymer systems, the development of AM processing of metals began and has evolved over the past three decades, with a number of fusion and solid-state processes emerging. However, they were much slower to develop, since they are much more directed at the fabrication of in-service components and are subject to more stringent performance requirements. Even though these AM processes are considered to be innovative, there are many similarities to other common manufacturing and material processing routes and there is much to be learned from these other fields. Fusionbased AM processes, for example, were originally adapted from welding, cladding, and surfacing, and they encompass the range of currently available directed energy deposition (DED) and powder bed fusion (PBF) processes. Solid-state processes, on the other hand, are more similar to traditional powder metallurgy and metal injection molding processes, in which the primary densification of the metal powder feedstocks is achieved through the use of polymer binders followed by high-temperature sintering processes. There are advantages to both processing routes, but most of the attention from researchers, academia, and many industrial segments has gone to the fusion-based processes.

Properties of feedstocks

While increased design freedom is very attractive and one of the more widely touted advantages of AM, an increased level of complexity in the material processing conditions results. Much of this emphasis has been on the role of changes in processing parameters, but the properties of the feedstock materials also play a large role in determining final properties. For PBF and most laser-based DED AM processes, the feedstocks are spherical pre-alloyed gas atomized powders on the order of 15 to 150 μm in diameter. It is also common to mix different feedstock powders to create custom materials or to vary the material composition during processing to fabricate high-performance, functionallygraded materials (FGM). In addition to the use of powder feedstocks, there is a growing use of wire feedstocks in wire arc additive manufacturing (WAAM) processes. In most cases, these wires are standard welding wires and utilize familiar compositions and product forms. The resulting component fabrication and material properties thus closely resemble large welded structures. Differences in the starting material feedstock composition and form, combined with the thermal histories experienced by the materials, set AM processing routes apart from more familiar wrought and cast ones. By starting with the alloy composition in this form, the processing of the material and the fabrication of the final component geometry are combined into a single step. Depending on the selection of the energy source (i.e. arcs, lasers, and electron beams), a range of different thermal histories characterized by a rapid series of repeated heating, melting, solidification, and cooling cycles produce a range of solidification structures that then go through a series of solid-state phase transformations to form the unique microstructures[5,6]. After processing, the resulting as-deposited components typically contain processing-related defects arising from lack of fusion between passes, keyhole collapse, and gas porosity. Because porosity can be a major failure propagation mechanism, as-fabricated additive manufactured components may require hot isostatic pressing to close pores for fatiguesensitive components. Wrought materials, on the other hand, undergo a complex and highly controlled series of thermomechanical processing steps to achieve consistent and uniform microstructures. Such stark differences in processing routes and microstructure inevitably lead to high levels of uncertainty in material properties. This uncertainty is at the core of many challenges facing the additive manufacturing field. Even with the efforts directed at defining the process-structureproperty relationships for AM fabricated materials, significant challenges still exist in matching the repeatable properties and performance obtained through traditional material processing routes. If the promise of AM is to be realized, even with such widely used materials as stainless steels, issues with materials need to be addressed.

Material challenges in additive manufacturing

AM processing technologies are increasingly viewed as an attractive option to move beyond prototyping and into larger-scale manufacturing and repair. Even though the applications for these AM processing technologies are expanding, there are fundamental limitations, particularly with respect to materials, that are hindering their more widespread use. It is widely accepted in fusion-based AM processes that in order for materials to be AM processed, they must be easily weldable. For welding researchers and engineers, this terminology is primarily directed at the susceptibility of the alloy to suffer solidification and solid-state cracking. Aside from the recognized high levels of property uncertainty, the availability of the alloys in the proper feedstock forms and the ability of the alloy system to be easily processed in the fusion-based techniques are also prominent concerns.

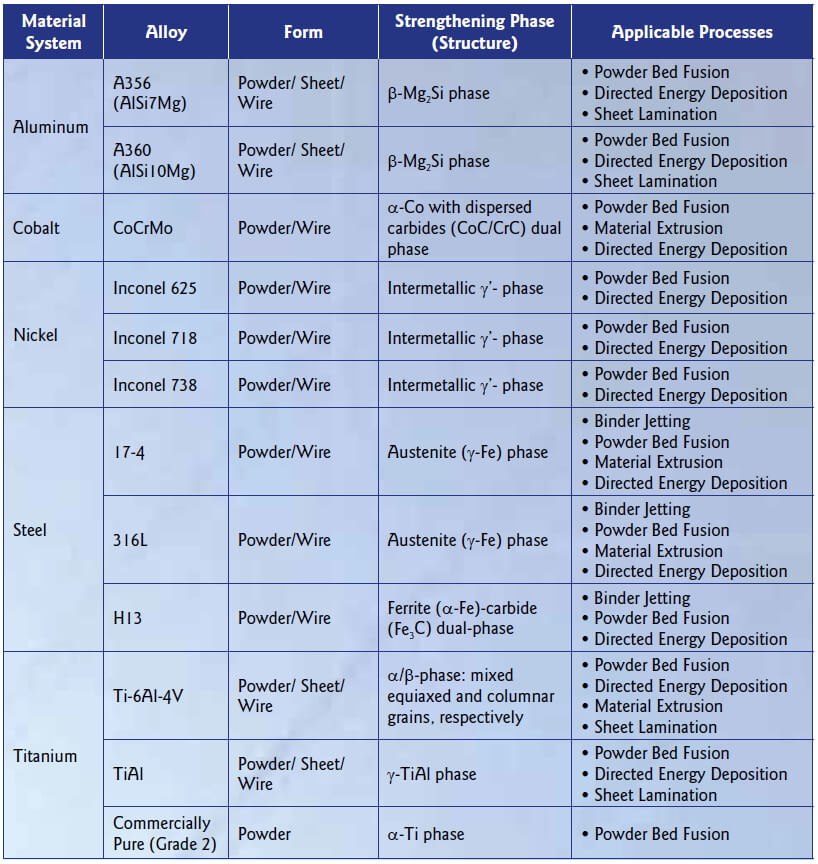

The number of alloys currently used for AM processing is limited by the availability of suitable metal powder feedstocks and the limitations on compositions to improve. For example, Table 1 provides a summary of common alloy systems used in AM processing.

This short list, while not comprehensive, easily covers the vast majority of alloys currently used in AM processing and almost exclusively contains alloys developed decades ago for wrought processing. Since these materials were originally designed for conventional processing routes, the significant differences in the thermal histories prevalent in AM processing produce unique structures and properties. Powder feedstocks introduce other complexities to the process through the introduction of minor alloying elements and changes in beam-material interactions. Recent work has shown that changes in composition, even within the specified composition ranges in austenitic stainless steels, martensitic precipitation hardened (PH) stainless steels, and solid solution strengthened nickel base alloys, impact the resulting microstructure and mechanical properties[5-7]. In the case of AM fabricated Inconel® 625, measured strength levels can differ by nearly 25% with small changes in the Fe, Si, and Ti compositions[5,6]. As a result, an in-depth understanding of the interdependent process-structureproperty (PSP) relationships between alloying elements, even minor ones which might have unknown effects on solidification and important solid state phase transformations, is critical. For example, the strength and heat treatment response of 17-4 PH grade stainless steel are significantly affected by the presence of different nitrogen levels, with high nitrogen levels leading to the presence of large amounts of retained austenite[7,8].

The complex interactions between multiple alloying elements make use of modern integrated design approaches essential to model these interactions across a range of processing conditions, and to identify modifications in materials, processes, and part designs needed to optimize performance.

Why are stainless steels popular in additive manufacturing?

Given their wide availability and generally good weldability, it is not surprising that austenitic, duplex, and martensitic PH grade stainless steels have been a popular alloy for both fusion and solid-state AM processing. They generally display low levels of common AM process-related defects, such as keyhole collapse and gas-induced porosity, across the different grades when processed using both fusion and solid state AM processing routes. In general, the properties of the AM fabricated materials fall in line with those expected for cast and wrought materials. However, the fusion-based AM processing routes are introducing additional complexity and resulting in unique behaviors and microstructures which vary across the different grades.

Since the various grades of stainless steels are designed for different applications and characterized by different compositions and processing routes in the wrought condition, it is not unexpected that AM processes will affect them in different ways.

As observed in fusion welding and other manufacturing processes, the microstructural and mechanical properties of AM components are influenced, in part, by the processing parameters that control temperatures, thermal gradient profiles, and cooling rates. For example, changing from a PBF to a DED process will result in significantly different microstructures and properties.

Over the next several issues, the AM processing of austenitic, duplex, and martensitic PH grades will be explored in more detail. As these grades have been further explored in the academic and technical literature, many of the differences between the materials in the wrought and AM conditions are being identified but not always adequately analyzed. In each grade, the properties of the feedstock materials, including the particle characteristics and compositions, are being shown to impact the resulting microstructure and properties of the as-deposited materials. These processing variables can also produce different structures and properties in feedstock materials with slightly different compositions, which in turn impact the physical properties of the alloy. When combined, the number of variables affecting the material properties and ultimately performance can become rather large, making it beneficial to explore specific alloys in each stainless steel grade individually.

References

[1] https://www.industrialheating. com/articles/94571-additivemanufacturing- the-next-industrial-revolution, accessed December 19, 2019.

[2] https://www.mckinsey.com/ business-functions/operations/ourinsights/ additive-manufacturinga- long-term-game-changer-formanufacturers, accessed December 19, 2019.

[3] T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson- Heid, A. De, W. Zhang, Additive manufacturing of metallic components – Process, structure and properties, Prog. Mater. Sci. 92 (2018) 112–224. doi:10.1016/j. pmatsci.2017.10.001.

[4] W.J. Sames, F.A. List, S. Pannala, R.R. Dehoff, S.S. Babu, The metallurgy and processing science of metal additive manufacturing, Int. Mater. Rev. (2016). doi:10.1080/09506608. 2015.1116649.

[5] Z.R. Khayat, T.A. Palmer, Impact of iron composition on the properties of an additively manufactured solid solution strengthened nickel base alloy, Mater. Sci. Eng. A. 718 (2018) 123–134. doi:10.1016/j. msea.2018.01.112.

[6] J.S. Zuback, P. Moradifar, Z. Khayat, N. Alem, T.A. Palmer, Impact of chemical composition on precipitate morphology in an additively manufactured nickel base superalloy, J. Alloys Compd. 798 (2019) 446–457. doi:10.1016/j. jallcom.2019.05.230.

[7] S.D. Meredith, J.S. Zuback, J.S. Keist, T.A. Palmer, Impact of composition on the heat treatment response of additively manufactured 17–4 PH grade stainless steel, Mater. Sci. Eng. A. 738 (2018) 44–56. doi:10.1016/j.msea.2018.09.066.

[8] D.J. Shaffer, A.E. Wilson-Heid, J.S. Keist, A.M. Beese, and T.A. Palmer, “Impact of Retained Austenite on the Aging Response of Additively Manufactured 17-4 PH Grade Stainless Steel”, Materials Science and Engineering A, 817, 2021, 141363. doi.org/10.1016/j.msea.2021.141363.