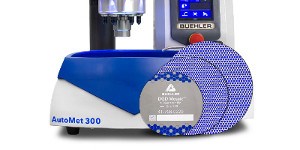

At Control 2019, Buehler ITW Test & Measurement, a leading manufacturer of instruments, consumables, and accessories for metallography and materials analysis, will be presenting its new Mosaic Diamond Grinding Discs (DGD). The fifth line of DGDs in Buehler’s grinding consumable offering, Mosaic grinding discs are designed to provide high material removal rates in sample preparation and are especially suited for demanding laboratories working with medium to hard alloys, and materials that are difficult to grind.

The new Mosaic diamond grinding discs are available with a magnetic backing and come in 8″, 10″ or 12″ disc diameters and in 120, 220, 320, 400 and 1000 grit sizes. Typical applications include the efficient grinding of steel, sintered carbides, thermal spray coatings, and other hard materials.

The new Mosaic Diamond Grinding Discs significantly reduce the time required for sample preparation in many industries. In the automotive sector, for example, Mosaic DGDs are used to grind hard and heat-treated steel and other alloys; in the aerospace sector, to grind superalloys and thermal spray coatings; or in tool-making, to grind samples made from cemented carbide.