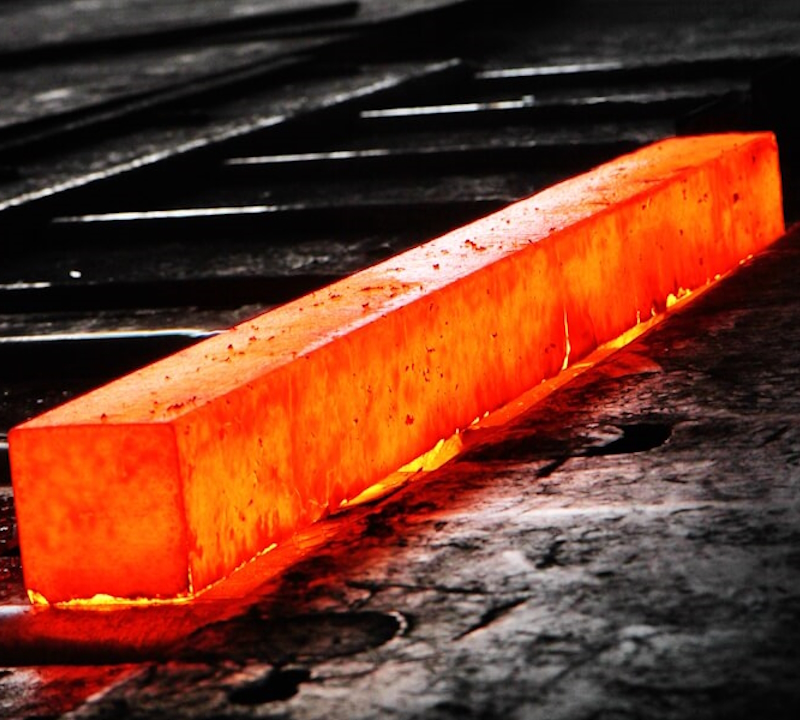

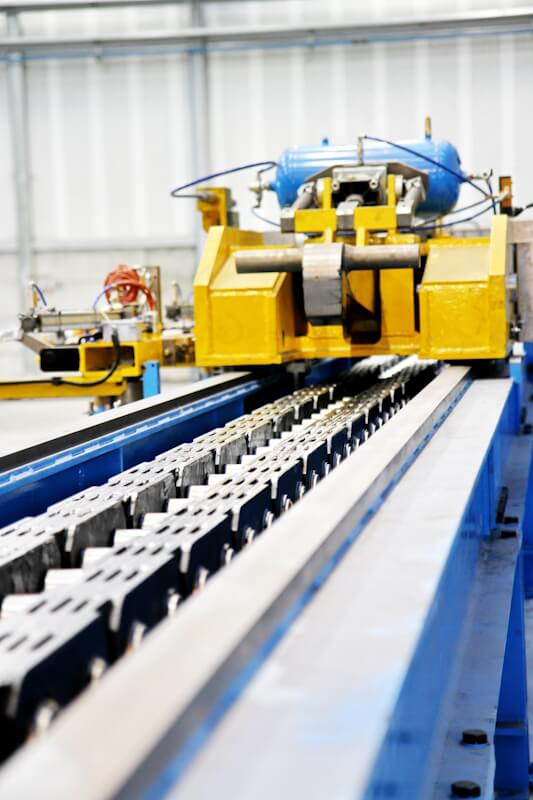

Production in Vieira de Leiria, Portugal. Photos: Böllinghaus Steel GmbH

In its 135-year history, Böllinghaus Steel GmbH has established itself as a leading supplier in the stainless steel industry. Through an exceptional combination of an extensive product portfolio, fast delivery, high flexibility and an uncompromising quality philosophy, the company has consolidated its position as a reliable partner for a wide range of industries. Today, under the management of Hartwig and Nina Härtel, the managing partners in the fourth and fifth generation, Böllinghaus Steel not only stands for quality, but also for innovation and sustainable growth. In an in-depth interview with Nina Härtel, the new CEO Jürgen Alex and CSO Philip Torger, we gained a deep insight into the company’s history, strategy and vision for the future.

By Sonja Wingels, Stainless Steel World

A success story with an unusual beginning The history of Böllinghaus Steel (formerly Remscheider Walz- und Hammerwerke Böllinghaus GmbH & Co. KG) began in 1889 with an unusual bet. Master butcher Herrmann Diederich Böllinghaus proclaimed that he was going to build a rolling mill in Remscheid, even though he had no experience in steel production. Fortunately, he was able to count on the support of his brother-in-law Johann Ludwig Härtel, who had the necessary expertise. This bet marked the beginning of a long success story that was to make the company a global player in the stainless steel industry.

Core business and strategic expansion

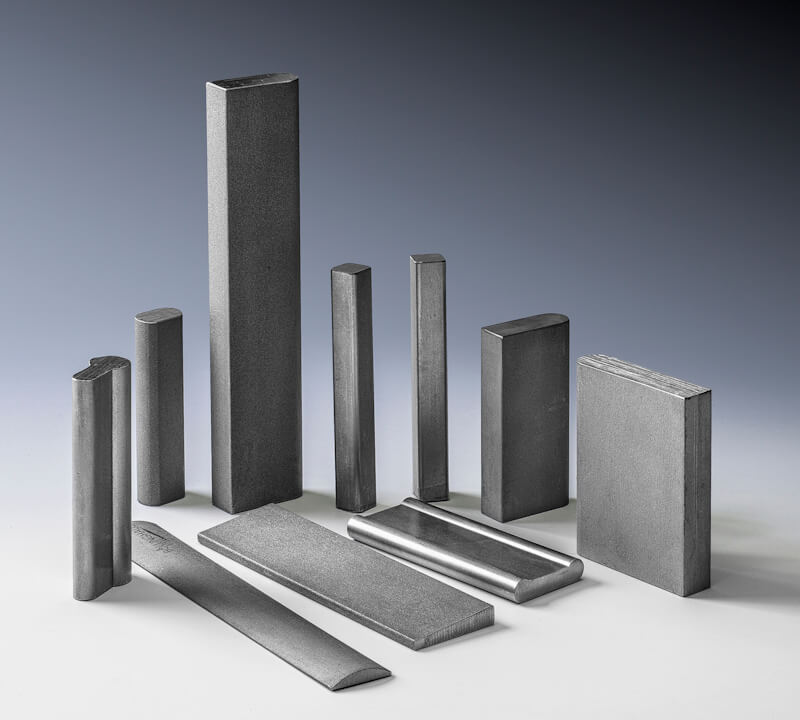

Böllinghaus Steel’s core business is the production of hot-rolled and cold-drawn stainless steel profiles, such as flat bars, hexagonal bars and square bars, which are used in numerous industries, including medical technology, aerospace and the oil and gas industry.

“Our large product range is due to the close proximity to the final dimensions of our profiles, which results in many individual, customer-specific solutions,” explains Jürgen Alex, the member of the management team responsible for sales and production. “This precise production saves our customers considerable amounts of material and processing time, which is both economical and saves resources.”

A significant turning point in the history of Böllinghaus Steel occurred in the mid-1990s when Hartwig Härtel decided to acquire the rolling mill in Vieira de Leiria, Portugal. This strategic decision proved to be extremely far-sighted, as the Portuguese site now forms the backbone of the company’s operational activities. The decision to operate production in Portugal and to continue investing there was supported by the good framework conditions and the logistical links to international steel markets.

“The proximity to deep-sea ports and a good road network is crucial for our ability to deliver, especially to the important American markets,” explains Philip Torger, Chief Sales Officer at Böllinghaus Steel. This infrastructure enables Böllinghaus Steel to respond flexibly to customer inquiries and adapt to the requirements of a wide range of industries.

Focus on growth and technical innovations

Böllinghaus Steel is currently in a phase of dynamic growth and technological renewal. As part of a multi-year investment program, the company is implementing projects in new rolling technology, new heat treatment technology, automation and further processing. These measures will enable the company to further expand its product range and open up new markets. “We have a clear strategic direction: we want to grow, and in various dimensions,” emphasizes Jürgen Alex. “More materials, larger dimensions, extended heat treatment and deeper processing – we will be investing in all of these areas in the coming years.”

One particularly demanding market in which Böllinghaus Steel has successfully gained a foothold is the aerospace industry. “The aerospace industry places very high demands on materials, processes and management systems. We have already successfully completed the necessary certifications and thus managed to enter this demanding market,” explains Jürgen Alex. “With its tight specifications and strict regulatory requirements, this market offers a good environment that opens up long-term growth opportunities for us.”

In addition to aerospace, Böllinghaus Steel is also focusing on forward-looking applications such as water extraction and the hydrogen industry. “Hydrogen is experiencing strong growth as an environmentally friendly energy source. Technical solutions are required for storage, transportation and regulated use, and this will also increase the demand for stainless steel solutions,” Jürgen Alex continues. Böllinghaus Steel is actively involved in the development of primary materials for stainless steel components for these growing industries.

Sustainability and social responsibility

As a family business that is aware of its social responsibility, Böllinghaus Steel focuses on sustainability in all areas of the company. “Sustainability decisions must also be made at management level,” emphasizes Jürgen Alex. An important part of the company’s sustainability strategy is to reduce its CO2 footprint.

“The main amount of CO2 in our products is produced during the manufacture of our raw materials. We are pursuing a clear strategy: ‘The greener the electricity, the greener our product’. This means that we buy from steelworks that produce their stainless steel from sorted scrap and preferably melted down using renewable energy.”

Böllinghaus Steel continuously invests in technologies to reduce its own emissions. One example of this is the decision to design burner systems in such a way that they can be operated with an admixture of hydrogen in future. “This is a step towards low-carbon production and shows that we are prepared to invest in innovative and forward-looking technologies in order to achieve our sustainability goals,” explains Jürgen Alex.

Sustainability is also actively practiced at employee level. In Portugal, employees have set up a composting station to recycle leftover food from the canteen. Additionally, the paper consumption has been reduced by 30 percent thanks to optimized processes. “Through close collaboration, intensive analysis and discussions with customers and suppliers, we were also able to significantly reduce packaging material,” reports Nina Härtel proudly.

The vision: shaping the future with stainless steel solutions

Böllinghaus Steel has a clear vision and mission that firmly anchors the company in the stainless steel industry. Three years ago, the company began working with its employees to define a common direction to ensure that everyone is pursuing the same goal. The vision is: “Böllinghaus Steel – Your partner for shaping the future with stainless steel solutions.” “The motto deliberately plays with the idea that the company not only shapes stainless steel products, but also shapes the future,” says Nina Härtel. The mission, which has been pursued since the company was founded in 1889, emphasizes the pursuit of innovative and sustainable products in order to offer customers real added value. This goes hand in hand with the goal of being both a reliable partner and a good employer.

Böllinghaus Steel’s success is largely based on a qualified and motivated team. The values that characterize the company are team orientation, creativity, innovation, flexibility, solution orientation, responsibility and solidarity. These values are reflected in the way Böllinghaus Steel conducts its business and interacts with its customers, suppliers and employees. As a family business, Böllinghaus Steel attaches great importance to treating each other with respect and appreciation, both within the company and towards customers and suppliers. These principles are not just guidelines, but a living reality that make Böllinghaus Steel successful in a highly competitive market.

A strong corporate culture and employee satisfaction

Böllinghaus Steel attaches great importance to a family-like corporate culture in which the appreciation of employees takes center stage.

“Böllinghaus lives this family corporate culture. That’s why it’s important to us to give something back to our employees. Not only through financial benefits such as a company retirement plan, but also through gestures of appreciation such as the annual Christmas party or birthday presents,” emphasizes Nina Härtel. Flexible working hours and continuous training are further measures that contribute to high employee satisfaction.

In Portugal, where Böllinghaus Steel is the largest employer in the region, the promotion of young talent plays a central role. “There are few steel-specific training opportunities there. That is why we invest in the qualification of talented people from our own ranks,” explains Torger. Cooperation with universities and educational institutions is essential in order to secure the next generation of skilled workers.

The company also offers dual study programs and internships in Germany to get young people interested in Böllinghaus Steel.

Böllinghaus Steel in the European stainless steel market: between opportunities and challenges

Böllinghaus Steel has established itself as a major player in the European stainless steel market and contributes to strengthening the steel industry with its production facilities in Portugal and the use of predominantly European raw materials. The company offers a broad and specialized product portfolio, making it an important supplier of high-quality stainless steel profiles. However, despite this strong position, Böllinghaus Steel faces considerable challenges. The European stainless steel market is increasingly burdened by cheap imports from Asia. These imports come from countries where production costs are significantly lower due to cheaper raw materials, lower electricity prices, less stringent environmental regulations and government support. Jürgen Alex explains: “These unequal competitive conditions make it difficult for European companies to remain competitive.” The high energy costs in Europe, exacerbated by the war in Ukraine, pose a massive challenge for the production of electrical steel in particular, as electricity is the biggest cost driver here alongside alloying costs.

These market distortions are leading to increased dependence on imports, as production outages and capacity bottlenecks in Europe are unable to meet demand. “The more imports overstocking the market, the more prices come under pressure, which further weakens domestic production. We are therefore consciously focusing on primary materials from Europe to counteract this trend,” emphasizes Jürgen Alex.

Philip Torger, CSO at Böllinghaus Steel, adds: “The current market conditions are made even more difficult by the fact that the European Union has not introduced sufficient regulatory mechanisms to protect domestic producers. We have to constantly adapt and play to our strengths to survive in this difficult environment, but we would also like to see more support and political protection.”

Despite these adverse circumstances, Böllinghaus Steel has shown itself to be resilient and adaptable. “For me, true success does not lie in individual achievements, but in the ability to demonstrate resilience over more than a century and to constantly realign ourselves,” explains Nina Härtel. “In an industry that is characterized by constant ups and downs, we have shown that we are able to stay on course and maintain our partnerships even in difficult times. This loyalty and the partnership-based relationship with customers, suppliers and employees have enabled us enabled us to overcome challenging times and to look optimistic about the future. Our previous generations, in particular my father Hartwig Härtel, have significantly shaped this foundation.”

Facts and figures:

| Founded: | 1889 |

| Management: | Hartwig and Nina Härtel and Jürgen Alex |

| Headquarters: | Hilden, Germany |

| Production site: | Vieira de Leiria, Portugal |

| Sales offices: | Chicago, USA and Milan, Italy |

| Employees: | around 300 worldwide |

| Products: | Stainless steel profiles (hot-rolled flat steel and square steel and cold-drawn flat, square and hexagonal steel) and special profiles |

| Contact: | +49 2103 88 010 – 0 info@boellinghaus-steel.com |

About this Featured Story

Appearing in the October 2024 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.