AWMA Water Control Solutions designed and constructed one of the world’s largest fish-friendly water extraction systems, using nickel-containing stainless steel.

Text by Lissel Pilcher, ASSDA

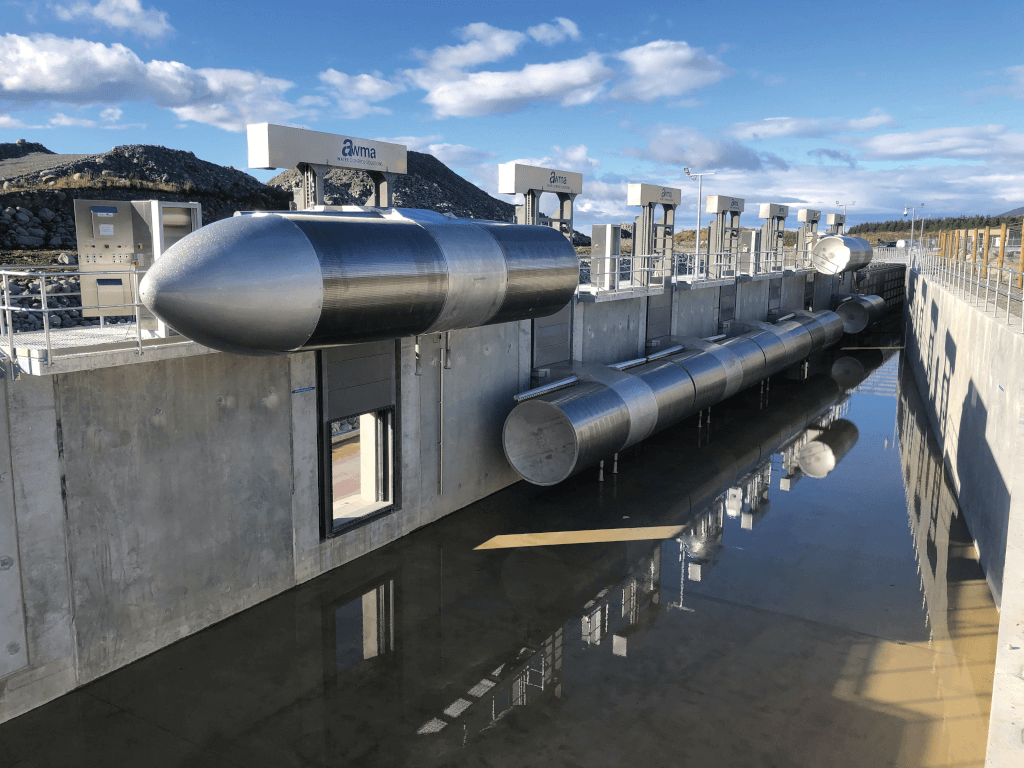

The Rangitata Diversion Race (RDR), completed in 2022, plays a crucial role in extracting water from the Rangitata River in New Zealand’s South Island, serving irrigation, stock water, and hydropower generation needs year-round. However, the environmental impact on native fish populations was a concern that instigated the development of an innovative new screening solution.

To address this challenge, an environmentally sustainable diversion system was designed and fabricated from nickel-containing Types 304 (UNS S30400) and 316 (S31600) stainless steels. This screening solution delivers the required flows while ensuring the safe passage of sporting fish, such as salmon and trout, as well as various endangered native fish species back into the river system.

Stainless screening system

Comprehensive research led to the selection of a physical, self-cleaning, wedge wire screening system, proven through decades of successful performance. This effective solution featured a stainless steel screening structure that was not only self-cleaning and fish-friendly but also delivered reliable water flows with a low whole-of-life cost.

The project required seven T-Screens (a total of 14 cylinder screens), a Flat Panel Screen, and a LayFlat Gate, all fabricated using stainless steel.

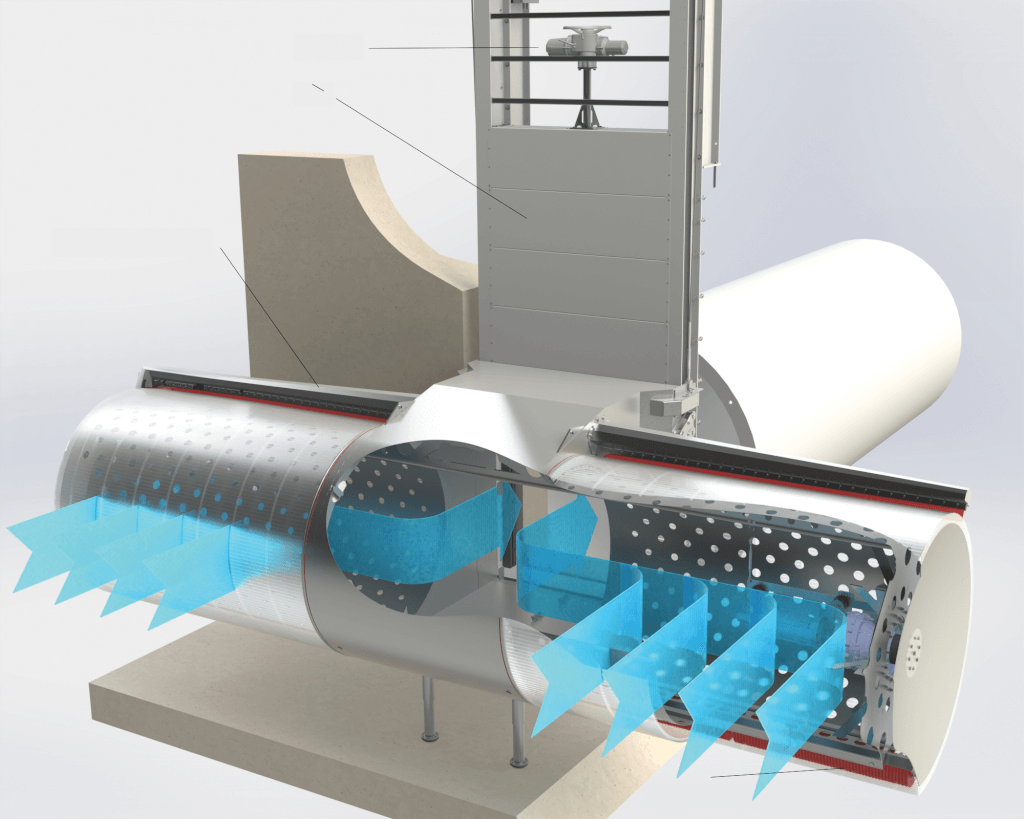

Three main design characteristics prioritised for the fish protection screens were aperture size, approach velocity, and self-cleaning functionality. The aperture size of the screens was tailored to meet the specific aquatic life present, considering fish species and breeding patterns. Low approach velocities prevent entrainment and impingement of debris and fish through low, even flow distribution across the entire screen area.

The screens, fabricated from stainless steel wedge wire, include a self-cleaning capability that incorporates internal and external brush cleaning mechanisms to efficiently remove debris and algae while maintaining fish protection and optimal flow.

The 14 cylinder screens were fabricated from Type 304 stainless steel wedge wire screen mediums, measuring 2.1 m in diameter and 3.0 m in length.

The seven, 8.75 m high retrieval systems were each fitted with headstocks consisting of Type 304 stainless steel headstock covers to protect the Type 316 stainless steel drive shafts that were 100 mm in diameter. 140 m of Type 316 stainless steel wire rope cables, complete with stainless turnbuckles and fittings were required for the purposes of lowering and raising the intake screens. The 8-tonne stainless steel flat panel screen measured 30 m x 3.5 m (105 m2).

Approximately 1.8 tonnes of stainless steel was used to fabricate the LayFlat Water Control Gate utilised at the end of the bypass channel as a fish-friendly, overshot gate for water regulation and control.

Prior to installation, a pickling surface treatment was performed on all stainless steel components.

Durability, performance, longevity

In total, over 55 tonnes of stainless steel were used for the manufacture of the screening system. Stainless steel has ensured the durability, performance, and longevity of the water extraction facility with a 50+ year asset life expectancy in fresh water. The combination of high-quality stainless steel materials and innovative infrastructure design has resulted in an environmental solution that delivers high-quality water output, reduced energy consumption, and reliable flow delivery while ensuring native fish protection.

Abridged from an article featured in Australian Stainless Magazine Issue 78.

About ASSDA

The Australian Stainless Steel Development Association (ASSDA) was established in 1992 with the aim of harnessing and addressing the industry’s growth in Australia. By promoting, educating,

and training industry professionals, contributing to standards development, and providing technical expertise and fabricator accreditation, ASSDA actively fosters the understanding and use of stainless steel. For information see www.assda.asn.au

About this Tech Article

Appearing in the February 2025 issue of Stainless Steel World Magazine, this technical article is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.