The goal of the NEWMAN project (Nickel frEe poWders for high-perforMAnce compoNents) is to drastically reduce the amount of nickel in the metal sintering contest. The project, supported by EIT RawMaterials, is demonstrating the actual impact of nickel-free powders for the production of high-performance components, in particular looking to three relevant aspects: economic validation, mechanical performance validation, environmental validation. These three validation actions are carried out simultaneously, and the results are continuously shared among partners, thus creating powerful synergies to maximize the nickel-free powders’ performance. Such demonstration is done thanks to two industrial end-users, Centro Ricerche Fiat (CRF) and VICIVISION.

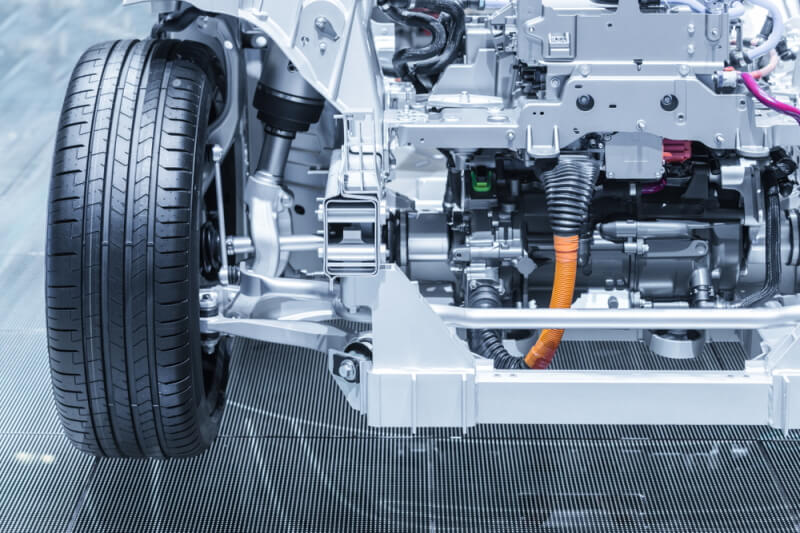

CRF is testing the new nickel-free process (NFP) developed within the NEWMAN project (Astaloy 85Mo) for the manufacturing of shifter shaft sleeves of an automotive gearbox.

VICIVISION is substituting the pinion of the upper tailstock group of its quality inspection machines. The re-design phase of this component aimed to define a new geometry able to meet the requirement imposed by Powder Metallurgy technology. It optimizes the assembly operations and increases the reliability of the new component, thus offering VICI’s customers a more reliable solution while considerably reducing its cost (approx. 80%).