ABB has successfully installed ABB Ability™ Asset Vista Conditioning Monitoring for metals at the CELSA III MBM mill in Barcelona, to help improve equipment reliability, prevent unplanned downtime, optimize maintenance and increase overall plant efficiency and productivity.

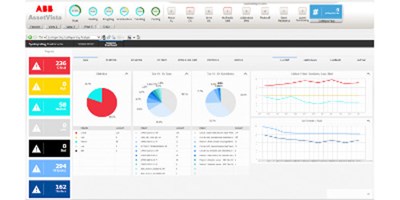

The ABB Ability™-based application monitors the health of a variety of production assets, including automation, instrumentation, electrical, mechanical and/or process equipment. It offers CELSA a complete overview of its production assets’ health, avoiding unnecessary maintenance, reducing exposure to hazardous areas and speeding repairs.

ABB Ability™ Asset Vista Conditioning Monitoring for metals will initially collect real-time data on the condition of common equipment across CELSA’s bar mill including hydraulic units, lubrication devices, motors, drives, and sensors. In the future, it can be scaled up to assess and evaluate the health of more complex, specialized assets and components to cater to changing business demands.

The solution offers operations, automation and maintenance engineers an in-depth overview of the performance of plant equipment and systems.