Continuum Powders has announced the commercial availability of two new copper-nickel alloy powders, OptiPowder C715 and OptiPowder C964, engineered for exceptional corrosion resistance, thermal and electrical conductivity, and mechanical stability in harsh operating environments. Produced through Continuum’s proprietary Greyhound Melt-to-Powder (M2P) process, both alloys are manufactured using certified reclaimed feedstock to deliver high-performance powder solutions with significantly reduced environmental impact.

Developed for demanding marine, energy, and industrial applications, the new CuNi powders provide outstanding resistance to seawater corrosion, stress-corrosion cracking, and high-velocity erosion. Their balanced compositions and stable mechanical behaviour across broad temperature ranges make them well suited for LPBF, EPBF, binder jetting, HIP, and DED platforms, as well as thermal spray and other advanced manufacturing processes.

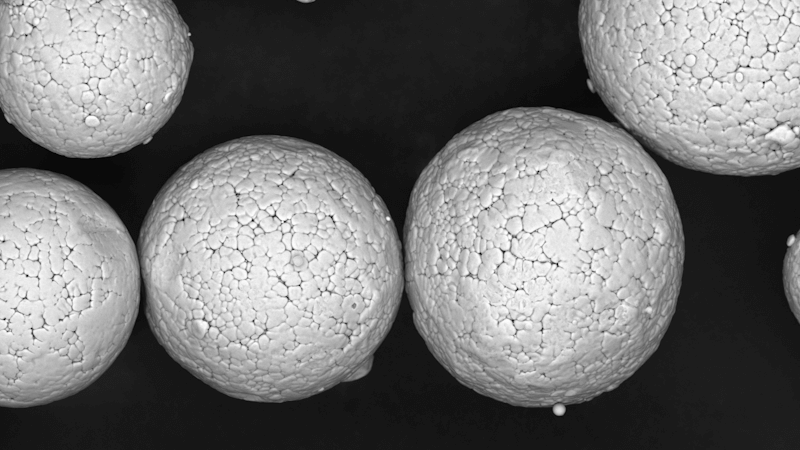

OptiPowder C715 and OptiPowder C964 are produced using Continuum’s M2P atomization technology, which transforms reclaimed aerospace-grade metal into high-purity, spherical powder with consistent flowability and morphology.

By manufacturing these alloys from reclaimed materials and maintaining purity through strict analytical and process controls, Continuum helps manufacturers reduce material waste, strengthen supply chain resilience, and advance measurable sustainability outcomes in metal additive manufacturing.