They say luck makes giants, but Sun Mark Stainless believes that it’s simply the name given to relentless willpower. What began as a single dream has now grown into a company where three generations work together, each bringing their own expertise, insight, and passion to the table.

The founders’ determination laid the foundation, the next generation expanded capabilities, and today’s leadership drives innovation while staying true to the values that built the company.

By Joanne McIntyre, Stainless Steel World

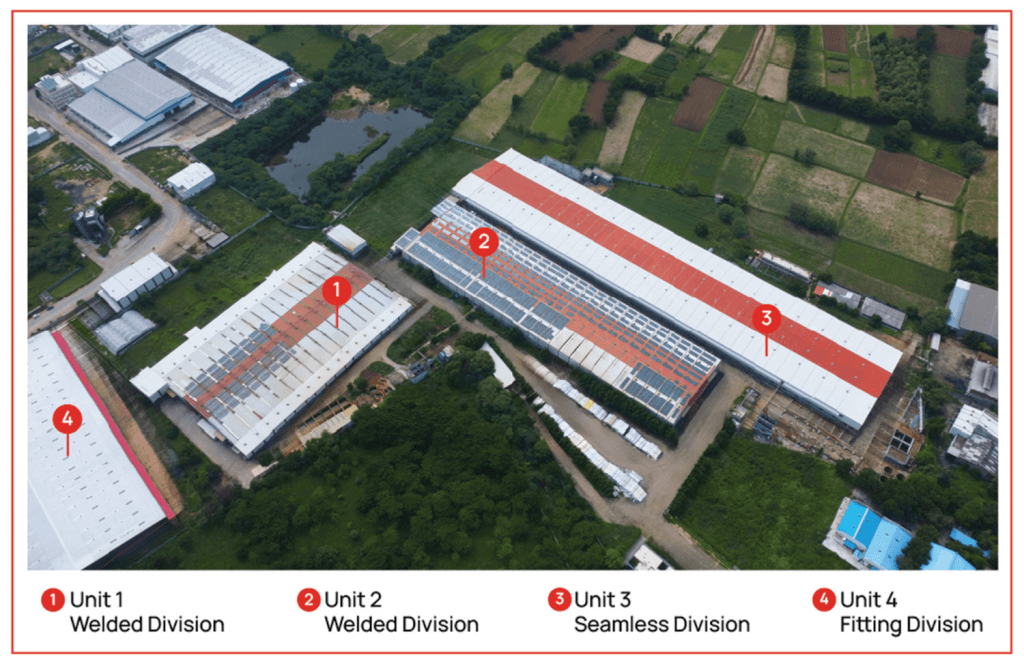

Situated in Ahmedabad, Gujarat, India, Sun Mark Stainless operates across four manufacturing units spread over 100 acres of high-tech facilities. Together, these units employ around 1,500 people and have an annual installed production capacity of 43,500 MT of stainless steel welded pipes & tubes, 24,000 MT of stainless steel seamless pipes & tubes, 3,000 MT of LSAW pipes, cold-rolling of stainless steel coils & precision foils, and butt-weld fittings.

Each facility is outfitted with cutting-edge machinery and automated systems, ensuring unmatched precision, efficiency, and consistency at every stage of production.

Building a dream

“My father had a dream to build something truly big,” explains Mr. Pratik Shah, Managing Director of Sun Mark Stainless. No investors. No strategic partners. Just pure willpower. For that dream, his mother gave him everything she had, all her savings. That kind of faith, that kind of love changes everything.”

“My father had a dream to build something truly big,” explains Mr. Pratik Shah, Managing Director of Sun Mark Stainless. No investors. No strategic partners. Just pure willpower. For that dream, his mother gave him everything she had, all her savings. That kind of faith, that kind of love changes everything.”

“With that strength, he founded the Sunrise Group over 45 years ago. Sun Mark Stainless, established in 2015, is the latest chapter of that vision.”

“We’ve scaled up, yes. But at the core, nothing has changed. That same willpower flows through generations, and our singular focus remains the same: engineering by heart, and piping ahead with purpose.”

“As a family-owned business, key decisions can be made rapidly, and this truly helps both our company and our customers to thrive in the dynamic stainless steel business. When a quick decision needs to be made, we immediately think of the consequences for both ourselves and our clients to ensure it’s a win-win for everyone. This is a fast, flexible way business model with a short command chain.”

Powerhouse of stainless steel

Sun Mark Stainless sources only the finest raw materials, and every stage from initial processing to final packaging is controlled in-house. This ensures that every Sun Mark Stainless product meets the highest international standards of quality and reliability. Generations of expertise, vision, and relentless willpower converge here to deliver products trusted by clients across India and in over 32 countries worldwide.

“A good reputation takes years of hard work to build, but only one bad decision to lose,” stress Mr Shah. “Our legacy and reputation have been earned over time and are our true essence and wealth. That solid reputation in the market, with customers, end users and all who use our products, is the foundation on which our business is built. “

Stainless steel seamless tubes

| Specifications | ASTM, ASME, DIN EN, JIS (JAPAN), NF (AFNOR), ASME / ASTM, A312, Equivalent to EN & DIN Standards |

| O.D. | 12.70 mm to 101.60 mm |

| OD in Inch | 1/2″ to 4″ |

| Thickness | 0.80 mm to 3 mm |

| Length | Up to 12 meters in straight length. U bend tubes up to 24 meters |

| Process Features | Solution Annealed – Pickled & Passivated, Bright Annealed |

| Surface Finish | Pickled, Bright Annealed |

| Grade | 304 / 304L / 316 / 316L / 316Ti / 317 / 321 / DUPLEX |

Stainless steel seamless pipes

| Specifications | ASTM, ASME, DIN EN, JIS (JAPAN), NF (AFNOR), ASME / ASTM A312, Equivalent to EN & DIN Standards |

| O.D. | 13.72 mm to 219.08 mm |

| OD in Inch | 1/4″ NB to 8″ NB |

| Thickness | 1.24 mm to 8.18 mm SCH 5S / SCH 10S / SCH 40S / SCH 80S |

| Length | Up to 12 meters |

| Process Features | Solution Annealed – Pickled & Passivated |

| Surface Finish | Pickled |

| Grade | 304 / 304L / 316 / 316L / 316Ti / 317 / 321 / DUPLEX |

Seamless demand

The global stainless steel seamless pipes market is on a strong growth trajectory, valued at USD 5.81 billion in 2024 and projected to reach USD 9.00 billion by 2033, growing at a CAGR of 5.0% (Business Research Insights).

“As a leading stainless steel company, expansion is our responsibility,” says Mr. Aaditya Shah, Executive Director of Sun Mark Stainless. “We don’t just respond to demand, we anticipate it. Planning ahead has allowed us to evolve from a strategic vision into one of India’s largest manufacturers of stainless steel pipes and tubes.”

Gold Trophy

In July 2025, Sun Mark Stainless was awarded the Gold Trophy for the Highest Exports of Stainless Steel Pipes and Tubes from India by the Engineering Export Promotion Council of India (EEPC).

“The award, presented by the Government of India, recognizes our performance in the stainless steel welded product category,” explained Mr. Shah. “We are proud to be the highest-volume exporter in this category, in terms of both revenue and volume. This achievement reflects the dedication of our team and validates the way we serve our customers. We strongly believe in building long-term relationships with our clients, a principle that remains at the heart of our ongoing success.”

Scaling seamlessly: new factory, new products

While Sun Mark Stainless is already India’s largest producer of welded and seamless pipes, it has embarked on a massive expansion program to increase production capacity. In June 2025, Sun Mark Stainless launched a state-of-the-art Seamless Division, with an installed capacity of 2,000 metric tons per month for manufacturing stainless steel seamless pipes and tubes. The division combines advanced technology with craftsmanship.

Every stage of production, hot piercing, cold drawing, and solution annealing, is carried out in-house, ensuring complete control over quality. Each pipe and tube is made from premium-grade stainless steel and undergoes rigorous destructive and non-destructive testing to guarantee durability, safety, and long-term reliability, even in the most demanding industrial applications. With exports accounting for a significant portion of Sunmark’s business, the company welcomes collaboration with reputable partners abroad. “We have a very successful global strategy of working with master distributors. We respect the market dynamics in each region and ensure that we don’t disturb that,” explains Mr Shah.

Seamless industries

With this expansion, Sun Mark Stainless continues to be a leader in the industry, delivering products that meet global standards while anticipating the evolving needs of clients worldwide. Its seamless pipes and tubes cater to a wide range of industries, including oil and gas, petrochemicals, power generation, chemical processing, pharmaceuticals, and infrastructure projects.

By delivering products that meet exacting standards, Sun Mark Stainless ensures clients across these critical sectors can rely on consistent performance and safety in even the most demanding environments.

Engineered by Heart

Sun Mark Stainless believes that profit, purpose, and people can go hand in hand.

As Mr Ruchit Shah, Director, says, “We don’t have to choose between the three; they belong together.”

Building on this, Mr Jignesh Shah, Joint Managing Director, adds, “For a company to grow, it must expand its product portfolio. For a company to scale, it must adapt a positive workplace environment for its people.”

At the core of Sun Mark Stainless is a philosophy of “Engineered by Heart.” The company invests as much in the quality and well-being of its workforce as it does in the excellence of its products. By prioritising people, nurturing talent, and ensuring a safe and supportive work environment, the company has created a culture where innovation, productivity, and loyalty flourish together.

Progress driven by tech

In the stainless steel industry, test certificates are lifeline documents. Recognising their critical role, Sun Mark Stainless has added a new dimension. By digitising the process, the company has enabled its customers to track their test certificates online, anytime and anywhere. For customers, it means freedom from paperwork, instant access during audits, and a seamless flow of transparency; for their customers, it offers the power to independently verify quality, strengthening confidence in projects and reputations alike. In a sector built on durability, Sun Mark Stainless has shown that the foundation of strength lies in trust made accessible.

Progress driven by tech

In the stainless steel industry, test certificates are lifeline documents. Recognising their critical role, Sun Mark Stainless has added a new dimension. By digitising the process, the company has enabled its customers to track their test certificates online, anytime and anywhere. For customers, it means freedom from paperwork, instant access during audits, and a seamless flow of transparency; for their customers, it offers the power to independently verify quality, strengthening confidence in projects and reputations alike. In a sector built on durability, Sun Mark Stainless has shown that the foundation of strength lies in trust made accessible.

Scaling responsibly

The company has invested in multiple initiatives to minimise its ecological footprint while maintaining world-class production standards. These include the installation of rooftop solar panels and a 40-megawatt on-ground captive solar park, which supply clean, renewable energy and significantly reduce reliance on conventional power sources. The in-house greenhouse enhances sustainability by supporting eco-friendly practices and optimising resource efficiency.

A cornerstone of Sun Mark’s environmental commitment is its Effluent Treatment Plant (ETP). Every drop of industrial wastewater is treated and reused, ensuring zero discharge into the environment.

As Mr Mahendra Shah, Chairman of Sunrise Group, emphasises, “At Sun Mark Stainless, we are committed to leaving no impact behind. Zero discharge is a responsibility we uphold in every process we run and in every decision we make.”

The company aims to achieve net-zero carbon emissions by 2030, with its renewable capacity ultimately supplying 100% of its electricity needs. All company vehicles, from forklifts to trucks that transport finished products to the shipping port, are being gradually replaced with electric vehicles. “While that process will take up to two years, by the end of 2025, we will have replaced all vehicles used by staff with EVs. They will be able to drive to work, charge their cars here, and return home powered by our solar and wind energy.” By integrating these sustainable practices with advanced production capabilities, Sun Mark Stainless has created a model of safe, responsible, and future-ready manufacturing. This approach reflects the company’s dedication to people, the planet, and performance, proving that environmental stewardship and industrial excellence can go hand in hand.

A rare combination perfected

In today’s fast-moving world, balancing quality with on-time delivery is no easy feat, but Sun Mark Stainless has mastered it. Every step of production is carefully overseen. Skilled teams use advanced tools to check material purity and integrity, catching potential issues before products leave the floor. Finished items are systematically organised and colour-coded, making large orders easy to manage and ensuring flawless, on-time delivery every time.

About this Featured Story

Appearing in the November 2025 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.