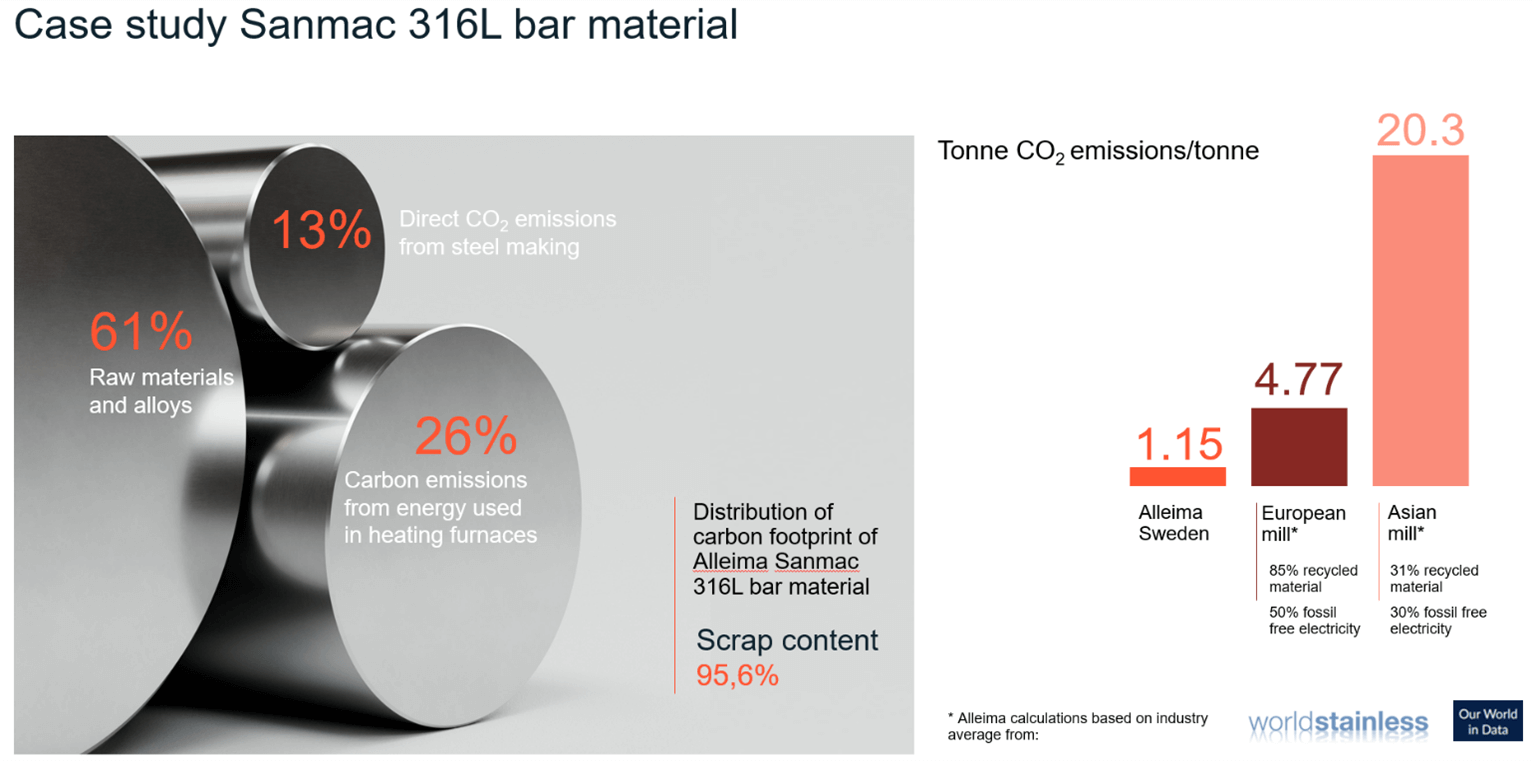

It is essential to know the percentage of recycled materials in an alloy to accurately calculate the LCA. Photo ©Alleima

Many companies within the metals industry are setting targets to reduce their carbon footprint in a necessary step to address the ongoing increase in carbon emissions each year. Since the beginning of 2024, Alleima has provided third-party verified carbon footprint data for its products, enabling customers to calculate the total carbon footprint of their products or systems. While other companies have also started doing this, it remains challenging to compare LCA data between different material producers.

By Marcus Hillbom, Business Development Manager, Alleima

For Alleima, the journey of mapping our carbon footprint at the product level began three years ago, in response to increasing customer questions. We quickly understood it was important to share this data with customers, as they had also signed up for decarbonisation initiatives.

We employed an LCA specialist tasked with collecting carbon footprint data, starting with our raw material producers and continuing downstream through the steel mill, hot-rolling mill, and further downstream processes. We contracted the Swedish Environmental Research Institute to support the LCA model and make informed decisions, such as cut-off points. This independent institute, funded by the Swedish government, has experience working with LCA since the 1990s in various industries.

Once our LCA specialist had worked through the data and began presenting the results, I was very excited. The first number I received was for a 316L bar: at 1.15 t CO2e/ton. As a Business Development Manager with an engineering background, I wanted to determine whether this was a good result. Upon comparing the number to available data, I observed a significant disparity between different material producers, even for similar products. Why was this the case? I began to investigate, and after reading through the standards, mapping the main influencing factors of carbon emissions, and more, I started to get a clearer picture.

Standards open to interpretation

The LCA standards we use – the ISO 14067 family – are the best framework available today for calculating the carbon footprint. However, standards are very general and not adapted to the steel industry. Additionally, the standards allow for individual interpretations, such as determining what constitutes a large or small emission, and when to establish cut-offs for carbon emissions. Giving the same task of calculating a product to ten LCA specialists will most likely give as many results.

That’s why it’s so important to have the guidance of a non-biased LCA expert in the process of setting up production routes and verifying the results. Alleima’s ambition is to be as transparent as possible and to present the LCA data with the highest accuracy.

In our industry, there is a lot of talk about green steel, but it is more of a concept than a tangible reality. There are no emission limits set for what can be defined as green or low-carbon emission steel. Therefore, many companies claim to be producing green steel based solely on their own definition.

At Alleima, we refrain from using the term’ green steel’ until we have a clear definition, to avoid misleading our customers. However, we do LCA calculations for our products to give our customers the chance to determine if we are green or not by their definition. The calculation of carbon emissions can vary even when the same LCA standards are used, depending on the Scopes included. Calculations made by Alleima show that Scope 3 is the main component of all emissions when producing stainless steel. Depending on the grade, Scope 3 emissions represent 60-90% of the total carbon footprint. So, to only calculate Scopes 1 and 2 and then claim to be a green steel producer is not a serious approach.

Defining green steel

The issue of comparing different material producers and defining green steel is recognised by ISO committees and organisations such as the IEA. Implementing new regulatory standards typically takes several years to finalise and publish. In the meantime, we have two options to consider.

Either the industry must start self-regulating to reach a consensus on how to calculate and report the carbon footprint of products, or alternatively, we need to educate consumers on how to make informed self-assessments of which products are better than others in terms of emissions to avoid misguided decisions.

I believe that one does not exclude the other, and knowledge needs to be shared throughout the supply chain so that we do not make misguided decisions. What the industry needs is something similar to WLTP (Worldwide Harmonised Light Vehicles Test, Procedure). Before this was established, all auto manufacturers had their own standards for calculating fuel consumption, which made it difficult to compare different cars. This is where we stand in terms of carbon emission calculation and reporting in the stainless-steel industry. To make stainless steel, you need two key ingredients: raw materials and energy. Manufacturers may choose to include recycled material or to extract the alloys from a mine. Typically, a melt consists of a combination, and this makes a tremendous difference to the carbon footprint. The main part of a product’s carbon footprint originates from the virgin alloys extracted from mines, which can be as great as 90% of the total carbon footprint of the materials.

The source of the raw materials also makes a significant difference. The term ‘responsible sourcing’ is increasingly used when purchasing raw materials, meaning sourcing raw materials with the lowest verified carbon footprint possible. For example, Nickel Pig Iron is not acceptable at Alleima due to the high carbon emissions associated with its production.

Access to fossil-free energy varies by country and region, which in turn influences the carbon intensity of the energy produced. Today, Sweden produces 98% fossil-free energy, with the majority coming from hydro, nuclear and wind energy. At the Alleima site in Sandviken, Sweden, we use electricity generated from 100% fossil-free sources. However, in countries like Germany, the energy mix remains heavily dependent on fossil sources (50%), whereas in Asia, the fossil dependency can reach as high as 90%. Even if electric arc furnaces (EAFs) are used the process cannot be considered green if fossil fuel-based sources, such as a coal-fired power plant, are used.

How Alleima calculate Sanmac 316L stainless steel bar

- Including scope 1,2,3.

- Following ISO 14067 and the ISO 14040/14044 family.

- All scopes (1,2,3 upstream) included, cradle to gate.

- Including production yield losses.

- No calculations using mass balance allocation.

- 3rd party reviewed by LCA expert (Swedish research and environmental institute). ― Accuracy of LCA compared to total carbon footprint of 93%.

- Cut off below 7% of total carbon footprint.

- No carbon offsetting (wind farms, planting trees, etc.)

- Result 1,15 tCO2e/ton material.

Example: Sanmac 316L using minimum requirements, offsetting and mass balance allocations:

- Following ISO 14067 and the ISO 14040/14044 family.

- All scopes (1,2,3 upstream) included, cradle to gate.

- Not Including production yield losses (calculate as co-product).

- Calculations using mass balance allocation. (bio-gas instead of LNG).

- Not 3rd party reviewed, (not a shall criteria if following ISO 14067).

- Accuracy of LCA compared to total carbon footprint of 80%.

- Using the highest possible cut off allowed of 20%.

- Carbon offsetting of 10%.

- Result 0,65 tCO2e/ton material

Figure 2. Alleima’s approach to carbon footprint calculation and reporting

Case study: Sanmac 316L

Let’s use the calculations of Sanmac 316L as a case study to illustrate how calculation results can differ due to a different mix of raw materials and energy. The average recycled material content in Alleima Sanmac 316L is 95.6%, an industry-leading number. The 4.4% of virgin alloys added provides 61% of the product’s total carbon footprint. When comparing with other regions, the energy mix and supply of recycled materials differ, having a significant impact on the total carbon footprint. The comparison is an example of using industry-average data, but it clearly demonstrates the importance of using clean energy and a high degree of recycled materials when melting stainless steel.

Back to the calculating and reporting. As stated, there are several ways to calculate and report the carbon footprint, and it is possible to set your own standard, depending on your company’s philosophy. At Alleima, we strive to be as transparent and accurate as possible in our LCA data, setting an industry benchmark for calculation and reporting. Even if the LCA standards for calculation allow room for interpretation, we let our LCA expert independently determine what should be reported. Figure 2 shows how calculations can be performed to yield different results. On the left is how Alleima performs its calculations, following the LCA standards, as this is the best framework available. It includes all scopes, including upstream Scope 3. As yield losses from all operations (depending on grade and product) can be 10-30%, it is important to include them for an accurate assessment. Alleima does not use mass balance allocation, a method that allocates all low fossil energy sources to a single specific product. One example could be heating furnaces. If a company uses 10% biogas and 90% LNG, using mass balance allocation, it could calculate much lower emissions for 10% of its products. But the remaining 90% will have much higher emissions. While this is not a recommended method by the standards, it is allowed. At Alleima, we don’t believe this is the right way forward, as it does not prioritise reducing the total emissions of operations, nor does it provide full transparency into a company’s sustainability efforts. Even if the standards allow a maximum 20% cut-off of the calculated values, Alleima reports a much lower value, in this case, 7%. We believe that a high degree of accuracy is essential, as it gives our customers greater confidence in the data. Finally, Alleima does not engage in carbon offsetting, such as building wind farms or planting trees to offset the negative impact of carbon emissions. This is because carbon offsetting does not address the main issue of lowering carbon emissions in the company’s operations. On the right side of Figure 2 is a calculation example of the same product, using the standards to report the lowest result possible while still being compliant.

This case study illustrates that, depending on one’s intentions, different outcomes can be achieved. Therefore, it is essential to inquire about the calculations used to make a self-assessment. To achieve this, you could ask the questions:

- What is the content of recycled raw material used in the melting process? A number above 80% is good.

- Are production yield losses accounted for in the calculations?

- What is the energy mix of fossil versus non-fossil electricity used?90% of fossil-free sources or more is a good value.

- Are all Scopes (1, 2, 3 upstream) included in the calculations?

- Have mass balance calculations been applied? If yes, then you can expect the actual emissions to be higher.

- Have the following standards been applied when calculating the LCA; ISO 14067 and the ISO 14040/14044 family?

- Is the result verified by a 3rd party, and do you recognise them?

The standards for calculating and reporting carbon emissions for stainless steel materials are not yet fully standardised. Alleima supports efforts to promote transparency and accuracy in carbon emissions, as well as initiatives to establish standards that enable customers to compare and choose materials with the lowest carbon footprint. We, as an industry, need to make it easy for our customers, and be more transparent. Alleima hopes that this method of calculation and reporting will set the benchmark for the industry moving forward, until updated standards are implemented.

About Author

About Author

Marcus Hillbom is the Business Development Manager at Alleima, where he leads a team of specialists in the fields of Life Cycle Assessment and Technical Marketing.

Marcus has more than twenty-five years of experience in the metal cutting and stainless steel industry, and has been with Alleima for over two decades.

About this Featured Story

Appearing in the August 2025 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.

About Author

About Author