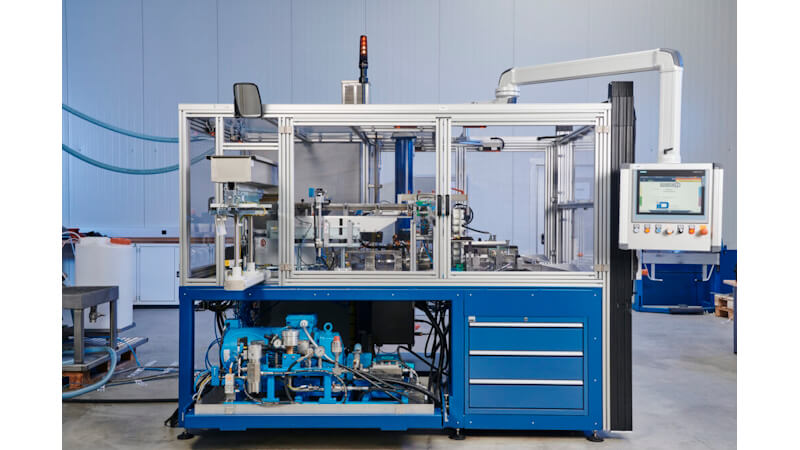

Schoeller, the manufacturer of longitudinally welded and redrawn stainless steel tubes, has successfully commissioned a new fully automated coiled tubing cleaning system together with its subsidiary, ID Ingenieure & Dienstleistungen GmbH.

With the new installation, the internal cleaning of coiled tubing is now fully automated and taken to a new level of efficiency. The process reliably removes lubricants from the drawing process on the inner surface of the tubes, combining chemical high-pressure cleaning with mechanical support through special cleaning elements. A digital production system automatically selects and parametrizes the appropriate cleaning programs based on tube dimensions, controlled via scanned barcodes and database queries. This ensures reproducible results, reduces manual work, and increases process reliability.

The development brings together Schoeller’s decades of experience in stainless steel tube manufacturing with the engineering and production expertise of ID.