Huzhou Jiuli Yongxing High Performance Metals Co., Ltd. (hereinafter Jiuli Yongxing) focuses on building relationships with global clients by offering them more than just products. They create added value with tailor-made material solutions featuring excellent service and quick response times. The company is particularly adept at meeting the extreme requirements found in critical conditions in a wide range of applications.

By the Stainless Steel World Editorial Team

Added value

Mr Li Zhengzhou, President of Huzhou Jiuli Yongxing High Performance Metals Co., Ltd. (Jiuli Yongxing) started the interview by stating: “At Jiuli Yongxing, we’re not only focused on supplying products to our customers; we are creating added value. When they place an order, our expertise ensures customers not only receive the product they need today, but also one that is fit for the future with the correct material and mechanical properties to guarantee the material performs successfully in their application. We can achieve this due to our extensive R&D capacity, combined with the capability of our facilities, which produce high-purity materials with excellent microstructure. Whether customers need materials for high- or low-temperature applications, high strength or superior corrosion resistance, we can create more value for them through careful material selection.”

Mr Zhengzhou explains that the company’s early involvement and technical communication with customers create significant added value.

“A lot of companies struggle to find the right person to provide expertise when it comes to material grade selection at the equipment design stage. Designing at that level needs to be done very early on in the planning process, so Jiuli Yongxing focuses on early involvement, which potentially saves the customer a lot of money later. In addition, the team provides a lot of technical communication with customers.

Jiuli Yongxing has a great deal of technical experience and is capable of communicating with customers at a deeply technical level to develop a better understanding of their needs.”

Case study: Quick response for critical requirements

A Middle Eastern oil and gas project faced urgent demand for a high-specification variety of N06625 material in small quantities and with a short delivery time. Under the premise of ensuring quality, Jiuli Yongxing leveraged the advantages of various smelting equipment and radial forging machines to customise a process plan and production for the customer. Jiuli Yongxing quickly organised the raw material smelting, forging/rolling, heat treatment, and other processes and successfully delivered within the specified delivery time, passing the customer’s quality inspection at one time. Ultimately, Jiuli Yongxing helped the customer save time and earned their praise.

From kilograms to hundreds of tons

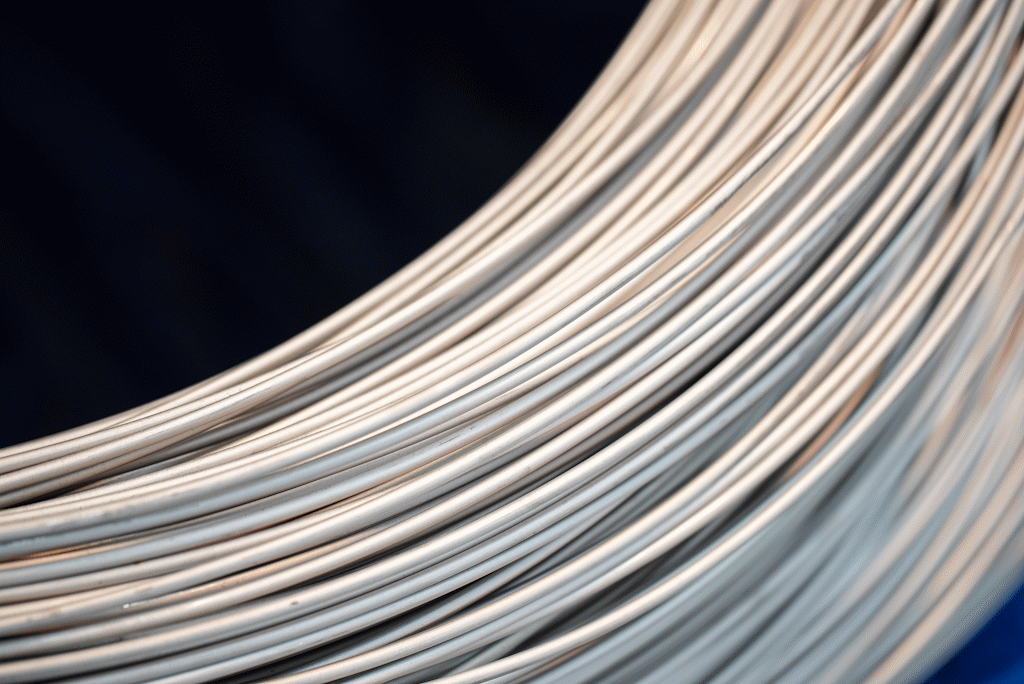

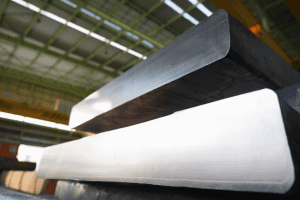

Jiuli Yongxing has vacuum melting and remelting equipment with various capacities, which can meet customer demands ranging from a few kilograms to hundreds of kilograms to hundreds of tons. The company can provide products such as high-temperature alloys, corrosion-resistant alloys, high-strength steels, and special stainless steels in various forms, including round/square bars, slabs, and wire rods, suitable for different working conditions. Jiuli Yongxing is also able to conduct small-batch research and development or trial production according to customer needs. Additionally, the company is in the process of setting up inventory warehouses close to global customer markets to address urgent customer needs quickly.

In contrast to many renowned manufacturers, Jiuli Yongxing has a very rapid decision-making process, which, combined with the team’s many years of experience, allows it to operate very efficiently for customers. They can rapidly get the response and materials they need.

Featured products

- Ultra-pure stainless steel: the content can be controlled to O ≤ 5 ppm, S ≤ 5 ppm; inclusions can be controlled with the size limited to ≤ 4 μm.

- N06625 materials exhibit both exceptionally superior corrosion resistance and high yield strength.

- N07718 alloy products meet or exceed standards such as ASTM & API & AMS Spec. In terms of microstructure, they can be supplied in conventional, fine-grained, ultrafine-grained, and other microstructural states according to the technical requirements of users.

High-performance materials

As a joint-venture subsidiary of Zhejiang Jiuli Hi-Tech Metals, Jiuli Yongxing has a solid foundation in providing high-performance materials to clients’ various demands.

Zhejiang Jiuli Hi-Tech Metals Co. is a professional pipe manufacturer with 37 years of development that exports products worldwide. It underpins Jiuli Yongxing with talent support, shared research and experimental resources, and the continuous pursuit of quality control, which is embedded in the company’s DNA.

The material properties of Jiuli Yongxing’s stainless steel grades offer significant advantages for customers, including ultra-high purity, high strength, excellent corrosion resistance, and superior high-temperature resistance, among others. The company’s manufacturing processes employ state-of-the-art technologies and equipment. Combined with their extensive experience, this allows them to provide customers with superior materials of better quality, purity, and microstructure.

Extensive material database

The Jiuli Yongxing team welcomes unusual requirements. With its steel laboratory accredited by internationally recognised organisations such as NADCAP, TUV, CNAS, etc., the company is equipped with a metallographic and microanalysis lab, a mechanical property testing lab, a chemical analysis testing lab, and a corrosion performance testing lab with hundreds of large and medium-sized devices. All of its materials undergo extensive testing, and after 37 years of accumulated research and development by its parent company, Zhejiang Jiuli Hi-Tech Metals Co., Jiuli Yongxing has built a powerful material database. The team can provide answers and solutions to any of the clients’ material-related issues.

Overcoming future challenges

With a strong R&D team, advanced research facilities, and extensive materials data accumulation, Jiuli Yongxing aims to recommend and select materials in accordance with customers’ needs, provide different quantities of production prototypes and conduct experimental verification based on customers’ designs, and work together to address the challenges posed by future new materials.

Case study: ITER

Jiuli Youngxing is committed to providing high-performance super stainless steel materials for the International Thermonuclear Experimental Reactor (ITER) program. Since 2014, leveraging the demand for tube products from its parent company, Zhejiang Jiuli Hi-Tech Metals Co.,Ltd, Jiuli Yongxing has independently carried out smelting and production with full-process quality control, supplying raw materials in stable batches every year.

Materials for an evolving world

Most of Jiuli Yongxing’s business is energy related. “Societal advancements, such as a desire for higher standards of living, are increasing the demand for safe, abundant, affordable and reliable energy,” explains Mr Zhengzhou.

“This is especially true for electricity, whether it is sourced from oil & gas, thermal plants, or renewables such as solar, geothermal, and wind. These sectors demand reliable, high-performance materials. We specialise in producing materials ideally suited to operating at higher temperatures while providing improved strength and critical corrosion resistance. Our core strength lies in our ability to manufacture these materials reliably.” Looking to the future, the Jiuli Yongxing team is also focusing on the aerospace market. It is pursuing qualifications and certifications related to the aerospace industry and has already obtained AS9100D certification.

While this is a new direction, aerospace raw material products are closely linked to demand for tubes from its parent company Zhejiang Jiuli, which means it can rapidly develop and supply products to meet the needs of aerospace customers. For example, Jiuli Yongxing is already in deep cooperation with major international aerospace clients regarding the supply of N07718 bars. In addition, Zhejiang Jiuli manufactures and supplies seamless pipes to international aerospace customers, with the raw material billets for these pipes being fully developed and produced by Jiuli Yongxing.

Strong global reputation

The company’s global client base recognises Jiuli Yongxing as a responsible company. Jiuli Yongxing also equates its customer’s success to their own success. The brand is reliable, responsible, and backed up by the experience and know-how to identify and deliver benefits to global customers.

Mr Zhengzhou adds: “We have the financial capability and the integrated capacity to produce various grades of material in a wide range of sizes and product forms. This means we can effectively operate as a one-stop solution for our customers. This can be explained as:

- Supply Assurance: In the global high-performance materials sector, our downstream customers, including equipment manufacturers, research institutions, and inventory distributors, often face challenges regarding the timely procurement of raw materials. The presence of Jiuli Yongxing provides customers with an additional choice, enabling us to respond to their material needs quickly.

- Joint R&D: We are positioned upstream in the entire metal material supply chain. With the continuous advancement of technology, the products of downstream customers are constantly evolving. Going back to the source, this undoubtedly involves the continuous optimisation and innovation of high-performance materials. We are capable of conducting synchronised R&D with our customers.

- Provide more cost-effective materials: Exceptional material products should be widely popularised and applied globally. Different countries have varying economic indicators, and in

the materials field, the same product may be used in different geographical locations. In addition to quality suitability being the primary factor, controlling material costs is also an important consideration. Jiuli Yongxing’s independent full-process production enables the company to offer more precise, customised material solutions based on the varying usage conditions due to geographical differences for different countries. This allows for controllable quality and cost management, ultimately reducing costs for customers right from the material source.”

“We strive to achieve continuous improvements in our production processes. Customers have an increasing need for higher quality and better delivery times, and this motivates us to improve continuously. Over the past thirty years, we’ve proven to be a very supportive brand for our customers, no matter where they are.”

Jiuli Yongxing’s sustainability achievements

EcoVadis Silver Medal: In recognition of its outstanding performance, Jiuli Yongxing was awarded the EcoVadis Silver Medal rating in December 2024, placing it in the top 15% of all companies participating in the rating globally. EcoVadis evaluates companies based on their performance in four core areas: environment, labour and human rights, business ethics, and sustainable procurement. Jiuli Yongxing’s achievement of the Silver Medal demonstrates its excellence in fulfilling social responsibilities and promoting sustainable development.

EcoVadis Silver Medal: In recognition of its outstanding performance, Jiuli Yongxing was awarded the EcoVadis Silver Medal rating in December 2024, placing it in the top 15% of all companies participating in the rating globally. EcoVadis evaluates companies based on their performance in four core areas: environment, labour and human rights, business ethics, and sustainable procurement. Jiuli Yongxing’s achievement of the Silver Medal demonstrates its excellence in fulfilling social responsibilities and promoting sustainable development.

Awarded Four-Star Green Factory title: Jiuli Yongxing has demonstrated outstanding performance in green and low-carbon production. As a company firmly committed to the concept of green sustainable development, Jiuli Yongxing not only adheres to measures such as low-carbon and carbon-reduction production but also actively promotes the achievement of carbon neutrality by 2050. These efforts reflect Jiuli Yongxing’s deep understanding and proactive actions towards environmental protection and social responsibility.

About this Featured Story

Appearing in the February 2025 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.