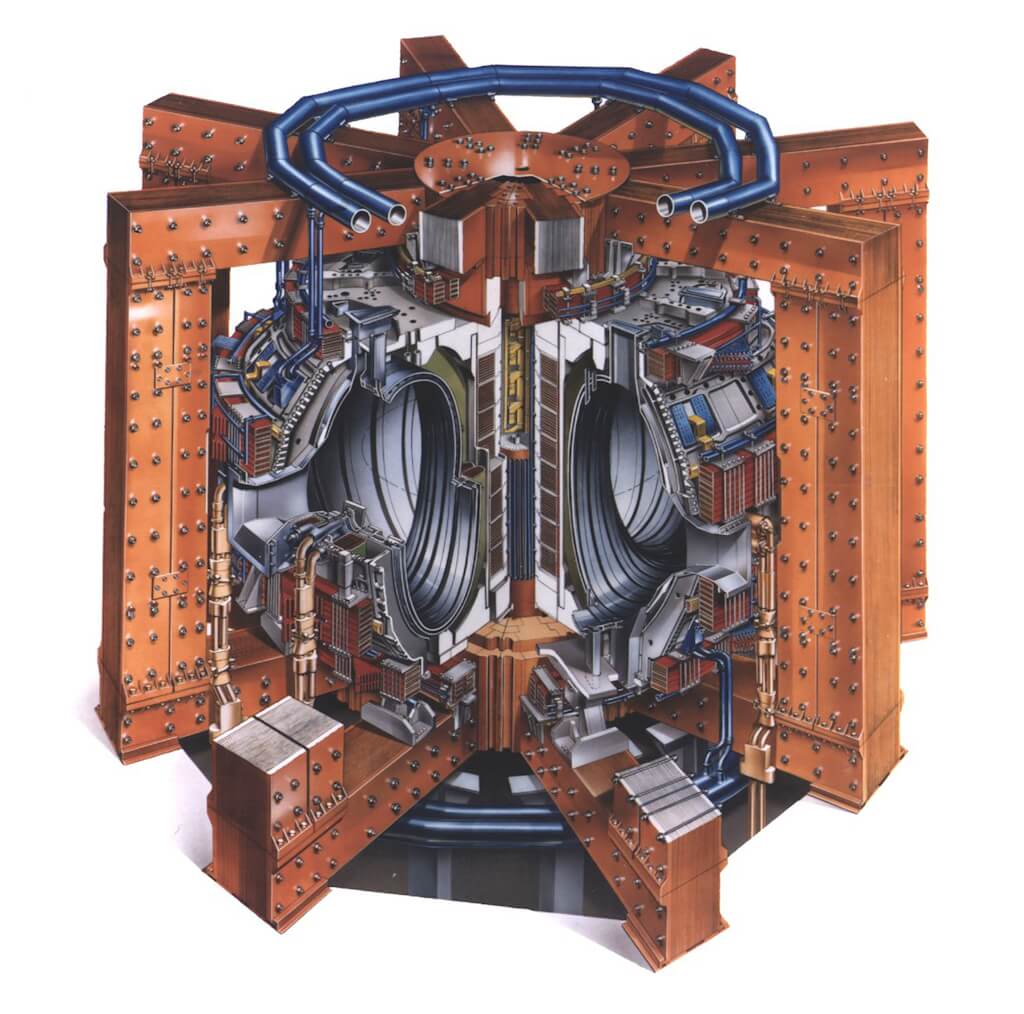

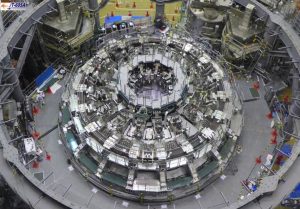

The interior of the JET reactor. Image © United Kingdom Atomic Energy Authority

Fusion is the same process that powers the sun and stars. It is environmentally friendly, safe, and capable of sustaining the planet for thousands of years. Currently, ninety nuclear fusion reactors are operating worldwide, and scientists across the globe are racing to achieve sustainable, commercial-level fusion energy.

By Joanne McIntyre, Stainless Steel World

Fusion works by fusing two light elements together, creating a new element with an aggregate mass slightly less than the combined mass of the original two elements. This tiny difference in mass drives a tremendous release of energy. Fusion does not generate long-lived nuclear waste, emit greenhouse gases, or pose a meltdown risk, and uses abundant, non-radioactive fuel. Yet successfully turning the theory into commercial reality has proven time-consuming and expensive. The idea has been around since the late 1950s, but it has moved forward dramatically in recent years to meet the growing demand for environmentally sustainable forms of energy. The successful implementation of commercial fusion power generation would give the world a seismic final push to meet the United Nations’ 2050 climate goals if implemented broadly and quickly. This would allow fusion to become the greenest, cleanest, and most affordable energy source for the planet.

Tokamaks, stellarators, accelerators

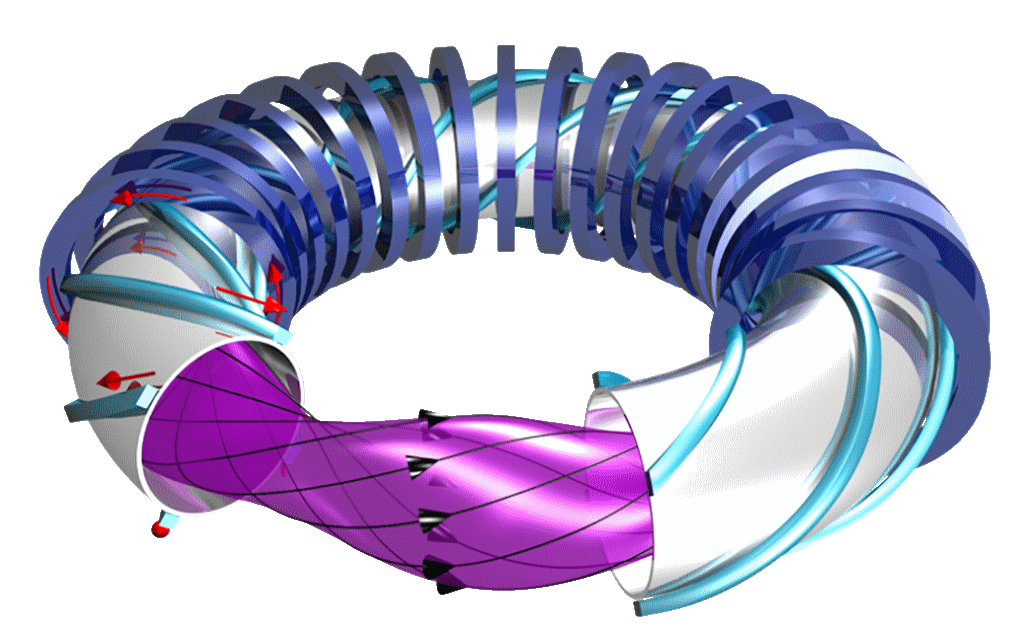

The most common fusion reactors are tokamaks and stellarators, which use strong magnets in the reactors to keep the ions confined. Currently, these are the most promising concepts for future fusion energy plants. Tokamaks are doughnut-shaped toroidal chambers with magnetic coils; twisting the magnets can also produce the helical shape without the need for a transformer — this kind of configuration is called a stellarator. As stellarator configurations are challenging to build, most fusion experiments today are tokamaks.

Both reactor types make use of the fact that charged particles react to magnetic forces. Strong magnets in the reactors keep the ions confined. Electrons are also bound by the reactors’ forces and play a role in the surroundings. The magnetic forces constantly spin the particles around their doughnut-shaped reactor chambers to prevent them from escaping the plasma.

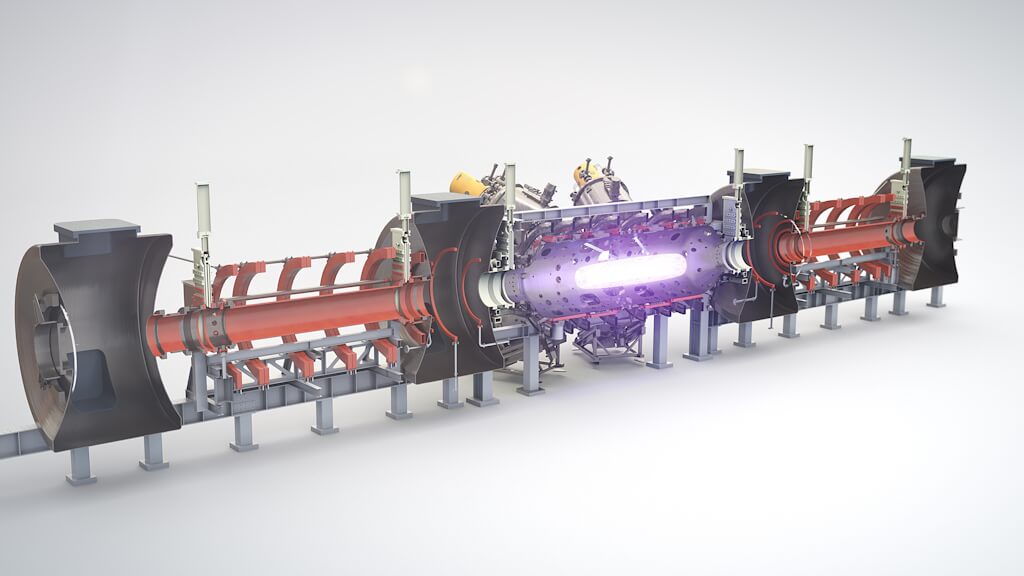

US company TAE has developed accelerator technology for its unique fusion reactor design.

On the grid by 2035?

In its Global Fusion Industry Report 2023, the Fusion Industry Association (FIA), which represents private companies pursuing fusion technology, stated that 25 companies think the first fusion plant will deliver electricity to the grid before 2035. Multiple companies are building “proof of concept” machines that will prove fusion as a viable energy source. A fusion industry will be important whenever it comes, but the sooner it happens, the sooner it can address the world’s energy challenges. FIA reports that the fusion industry has now attracted over USD 6 billion in investment, with 27 companies reporting significant increases in their funding levels last year.

Increased government involvement

Perhaps even more critical than the volume of money going into fusion is that the last year has seen policies, procedures, and public interest that will allow fusion to grow and mature rapidly, the FIA report states. Significant new public-private partnership programs were launched in several key nations in 2023, with eighteen companies reporting they were involved (or would soon be) in a public-private partnership with the government. Around the world, these programs are diverse in their aims and funding levels, but there is a clear trend towards government interest in fusion. The United States, Japan, and Germany made announcements in early 2023 about new programs to support fusion commercialisation, in addition to the already robust support in the United Kingdom.

In the number of private fusion companies, the US remains dominant, with 25 companies and the bulk of investment, but there has been important growth in countries like Japan, China, Australia, New Zealand, Germany, and Israel, while the UK and Canada have serious advanced contenders. Likewise, a regulatory framework for fusion – separate from nuclear fission regulation – is moving forward as well, with the UK being the first-mover, followed by a decision by the US Nuclear Regulatory Commission in April 2023. This regulatory certainty will de-risk fusion and could unlock further private investment.

Following are some examples of major fusion projects around the globe.

Stainless steel & fusion

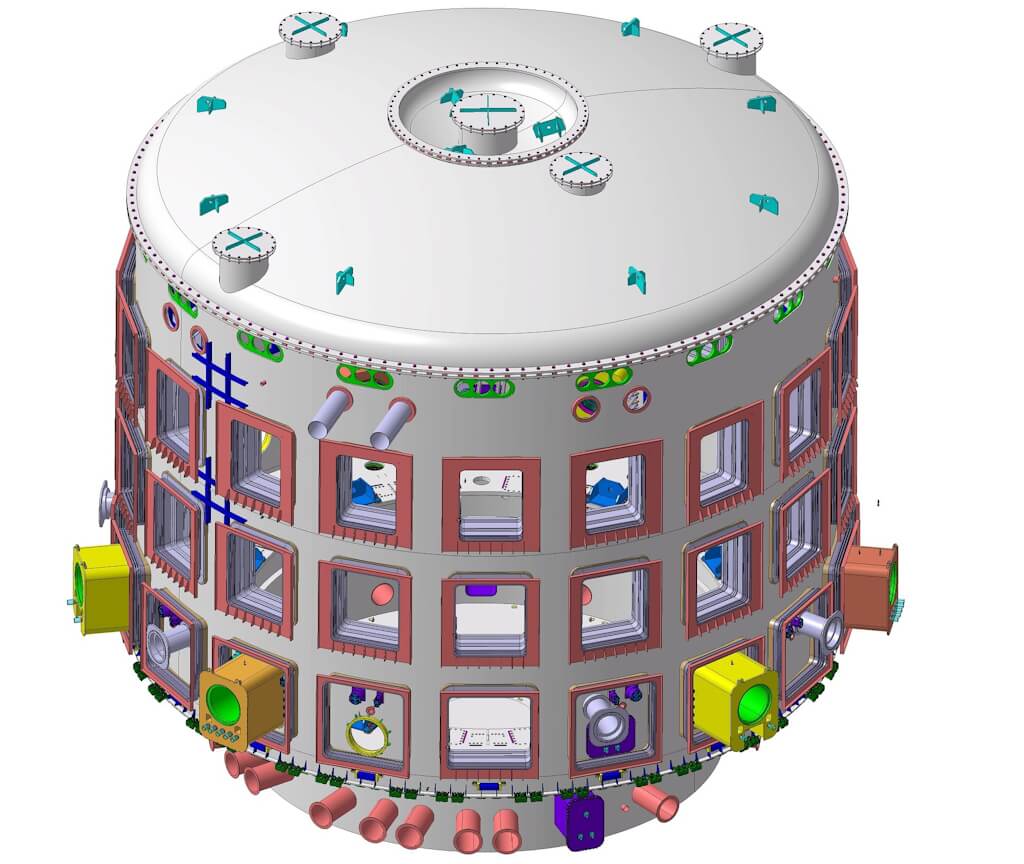

Fusion is important to the stainless steel industry because it requires vast amounts of high-quality materials. Examples from the ITER project include:

- The ITER cryostat—the largest stainless steel high-vacuum pressure chamber ever built (16,000 m³)—provides the high vacuum, ultra-cool environment for the ITER vacuum vessel and the superconducting magnets. Nearly 30 metres wide and high, the cryostat weighs 3,850 tonnes.

- ITERs vacuum vessels required over 1,000 steel forgings weighing up to 10 metric tons. These were made from 316 LN, an ITER-grade of stainless steel with low carbon and high nitrogen content.

- 40 blanket modules covering the inner walls of the vacuum vessel are made from beryllium, high-strength copper and stainless steel. The 40 mm-thick shielding plates made out of borated stainless steel 304B7 with about 2% boron content are used for neutron shielding.

- A 10 km network of seamless stainless pipes connects powerful vacuum pumps to the vacuum vessel, cryostat, and neutral beam injector.

- The Hot Cell Complex provides a secure environment for the processing, repair or refurbishment, testing, and disposal of ITER components that have become activated by neutron exposure. Around 30,000 m³ of the ‘red zone’ area within the Hot Cell Facility will be lined with stainless steel.

Mighty ITER

Currently under construction, the ITER Tokamak will be the largest ever built. It is a combined effort from 35 member countries involving thousands of scientists. The estimated EUR22 billion cost is covered by the seven ITER Members: China, the European Union (through Euratom), India, Japan, Korea, Russia and the United States. Components are manufactured all over the world, ensuring each member nation benefits from the process, then shipped to the site in Saint-Paul-lez-Durance, France, for assembly in the vast stainless steel clad assembly hall.

ITER will have a plasma volume of 830 cubic metres, a massive increase on the maximum plasma volume in tokamaks operating today of 100 cubic metres reached in both Europe’s JET and Japan’s JT-60. This huge plasma volume will enable it to produce a “burning plasma” in which the majority of the heating needed to sustain the fusion reaction is produced by the alpha particles generated during the fusion process itself. The production and control of such a self-heated plasma has been the goal of magnetic fusion research for more than 50 years.

The ITER machine will weigh 23,000 tonnes. The vacuum vessel alone, with its ports, blanket and divertor, weighs 8,000 tonnes. Inside the ITER Tokamak, temperatures will reach 150 million°C – ten times the temperature at the core of our sun.

The ITER Organization is now overseeing the integration and assembly of components delivered to the ITER site by the seven ITER Members. This includes the assembly of the ITER Tokamak, with its estimated one million components, and the parallel installation and integration of plant systems such as radio frequency heating, fuel cycle, cryogenic, cooling water, vacuum, control, and high voltage electrical.

JET’s tritium experiments

In February, the UK’s Joint European Torus (JET), one of the world’s largest and most powerful fusion machines, demonstrated the ability to reliably generate fusion energy whilst simultaneously setting a world-record in energy output. In JET’s final deuterium-tritium experiments (DTE3), high fusion power was consistently produced for 5 seconds, resulting in a ground-breaking record of 69 megajoules using a mere 0.2 milligrams of fuel.

JET is a tokamak, a design which uses powerful magnetic fields to confine a plasma in the shape of a doughnut. Most approaches to creating commercial fusion favour the use of two hydrogen variants – deuterium and tritium. When deuterium and tritium fuse together they produce helium and vast amounts of energy.

Dr Fernanda Rimini, JET Senior Exploitation Manager, said: “We can reliably create fusion plasmas using the same fuel mixture to be used by commercial fusion energy powerplants, showcasing the advanced expertise developed over time.”

TAE Technologies

Based in Southern California, TAE Technologies is one of the leading global fusion companies. With declared funding of over USD 1.2 billion, it is also one of the best-funded. The company is pioneering a visionary approach to fusion energy, combining advanced accelerator and plasma physics using non-radioactive, abundant boron as a fuel.

TAE says that its approach represents the fastest, most practical, and economically competitive solution to bring abundant carbon-free energy to the grid.

TAE’s fifth-generation reactor, Norman, was unveiled in 2017 and was designed to keep plasma stable at 30 million degrees Celsius. Norman uses a linear field-reverse configuration combined with intense neutral beam injection to sustain the plasma. Hydrogen gas is heated to form two smoke rings of plasma, which are supersonically slammed together. The rings merge in the middle, forming a spinning plasma held together by strong, self-created magnetic fields. Neutral beams are used to stabilise the plasma and achieve longer, higher temperature field reversed configurations.

In 2022, after Norman achieved temperatures greater than 75 million degrees Celsius and demonstrated real-time control of plasma in this state-of-the-art fusion research reactor, TAE Technologies announced that it had secured strategic and institutional investments to fund the construction of its next research reactor, Copernicus.

The Copernicus reactor is being built in a 100,000-square-foot facility in Irvine, California. By 2026, it should demonstrate the viability of achieving net energy generation with TAE’s advanced beam-driven field-reversed configuration (FRC)—the penultimate step on TAE’s path to commercialising clean fusion power.

About this Featured Story

Appearing in the August 2024 issue of Stainless Steel World Magazine, this Featured Story is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.