When considering painting stainless steel, the initial question arises: why paint it in the first place?

Text by ASSDA

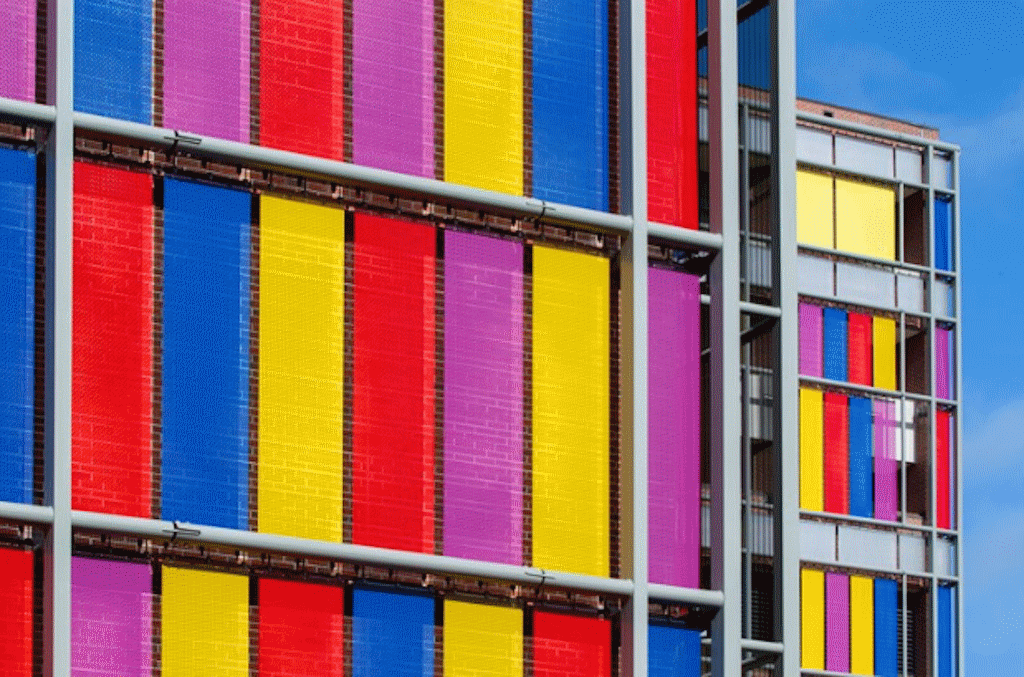

If the design choice is simply about colour or aesthetic purposes and the product form has a smooth surface (i.e., sheet or round products), using factory-supplied coloured stock attached to fasteners might be the preferable option. This construction method is commonly used for non-contact areas such as walls or facades, as exemplified in ASSDA FAQ 12: Coloured and patterned stainless steel.

Similarly, in new constructions, there are often reflectance limits to consider. While highly polished stainless steels offer extreme reflectivity, embossed surfaces, like the panels seen on the Petronas Towers in Kuala Lumpur, Malaysia, provide a bright appearance with lower reflectivity.

Clean profiled surface needed

However, if adding colour is necessary for an existing structure, painting stainless steel is feasible but requires certain precautions. Unlike carbon or galvanised steel, a primer undercoat will not form a chemical bond with the stainless steel surface, necessitating a clean and profiled surface to provide a mechanical key for adhesion. Profiling by chemical etching is possible, but safety concerns make using pickling acids impractical. A relatively mild etch profile can be achieved using oxalic acid, but the most common method of profiling involves abrasion either by blasting or using abrasive belts with aluminium oxide grit, which MUST be free of carbon steel. Garnet is used for blast profiling of carbon steel, but it is not recommended for stainless steel because of potential contamination from this natural mineral.

Before abrasive profiling, the surface must be free of grease and dirt, and any heat tint from welding or thermal cutting must be removed by pickling or abrasion. Due to surface tension, liquid coatings tend to draw back from sharp edges. This requires rounded edges as specified for painted carbon steel (refer to AS/NZS 2312.1 Protection of steel against atmospheric corrosion by the use of protective coatings: Section 3.4). In addition, if thin lacquers are used for an aggressive environment to reduce maintenance cleaning compared to a bare stainless surface, then a spider web of filiform corrosion can creep from sharp cut edges along the stainless-lacquer interface.

For small projects, it is not uncommon to use abrasive belts, with typically 80 grit size. If blasting is possible, it should provide a profile of 30 to 50 µm Ra for an inert primer, typically a two pack epoxy, with thickness at least three times the profile to ensure peak coverage and a similar thickness top coating of a UV-resistant formulation for exterior applications.

Choose coatings carefully

The coatings must contain less than 50 ppm of available chloride. It is critical that the primer is inert, as zinc-based primer systems will galvanically react with the stainless steel and degrade the coating. Other inhibitors may add expense without enhancing corrosion resistance for the stainless steel. These stainless profiles are much greater than the 0.5 µm Ra value for uncoated stainless steel because the surface profile for painting is about the adhesion of an aesthetic/protective coating rather than avoiding corrosion of a bare stainless steel.

With the right process, the successful application of paint on stainless steel will deliver both aesthetic appeal and enduring protection against corrosion, ensuring longevity and visual appeal of the structure.

Republished with the kind permission of the Australian Stainless Steel Development Association (ASSDA), a non-profit industry group that has been developing a strong and vibrant stainless steel industry in Australia since 1992. For information, visit www.assda.asn.au

About this Tech Article

Appearing in the September 2024 issue of Stainless Steel World Magazine, this technical article is just one of many insightful articles we publish. Subscribe today to receive 10 issues a year, available monthly in print and digital formats. – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new technical articles with our Stainless Steel community. Join us and let’s share your technical articles on Stainless Steel World online and in print.