As a responsible and respected steel distribution organisation, the team at Independent Tool Consultants Limited T/A INTOCO specialises in supplying high-quality raw and pre-machined materials. For over half a century, the UK company has built a solid reputation based on quality, supply accuracy, traceability to mill source, and rapid delivery. Stainless Steel World spoke to Managing Director Tony Preece to learn more about the business philosophy that has carried Intoco to the top of the industry.

By Joanne McIntyre, Stainless Steel World

From its headquarters in Cheltenham, UK, INTOCO ships specialist steels and alloys around the globe. Tony Preece explained that the company’s specialised shipping department ensures products are delivered on time and in perfect condition, protected in top-quality packaging. “Post-Brexit, we swiftly adapted to any logistical challenges, working closely with our customers to meet their needs with minimal disruption. For instance, our products reach customers in mainland Europe within 7-8 working days, a testament to the unwavering dedication of our logistics team.”

Specialised materials

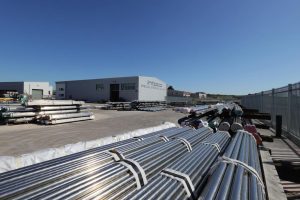

As one of the largest independent stockists and distributors of specialised materials in the UK, INTOCO prides itself on providing consistently reliable and rapid service to it valued customers, having fourteen saws with the capability of working ‘lights out’. Catering to industries that require the utmost quality and dependability, such as oil and gas, INTOCO supplies high-end alloys designed for the most demanding applications and have the ability to release material with full certification to OEM specifications. With over fifty years of experience, INTOCO’s efficient operations and well-organised factories reflect a deep commitment to quality control and customer satisfaction, ensuring every process meets the highest standards. Tony emphasises that the cornerstone of INTOCO’s ongoing success is its very high stocking levels. The stainless steels and nickel alloys it supplies range in size from 6.4mm to 710mm in diameter.

“Our motto is: ‘If you don’t have it, you can’t sell it’, and this has stood us in good stead over the decades,” he explains. “Our warehouses are fully stocked with around GBP 15 million pounds worth of stock, translating to around 2,400 tonnes of specialist alloys. As each order is processed, replacement stock is immediately ordered. INTOCO’s ongoing orders with steel mills with lead times of up to a year account for an extra 30% of stock incoming at any time. While markets may fluctuate, our customers know they can trust us to deliver what they need, when they need it.”

Active in demanding sectors

INTOCO primarily supplies steel to the oil and gas industry, with significant demand also coming from the food industry. “Our high-end alloys are integral to many demanding sectors, often utilised for critical parts and components. Our stainless steel customer base encompasses applications in the petrochemical, valve engineering, sub-sea, wind energy, and pharmaceutical industries.”

Quality Management System

James Whitehouse was bought into the business in 2021. Initially taken on as a Quality & Technical consultant, he is now employed by INTOCO

to represent the company as their Technical Manager of Special Steels & Alloys. His main aims are:

- To add value to the existing supply chain by reviewing & updating existing company purchasing documents to ensure the latest relevant international and customer specifications have been applied,

- To aid in the process of developing potential new supply chains, creating new internal purchasing documents following direct consultation with approved external providers,

- To add value to existing stock by applying additional release to customer specifications where suitable, on a case-by-case basis following enquiry submissions from the INTOCO Sales team.

James has also been given the further responsibility of maintaining the company’s Quality Management System, following on from his experience as a current ISO & AS series lead auditor.

A word from James: “INTOCO has been highly supportive in furthering my career in quality, technical and auditing aspects. I wholeheartedly welcome queries from our customer base and potential customers who have technical queries, or need advice regarding specification clarification in relation to special steels and alloys.”

“In addition, we at INTOCO are more than happy to accommodate customer audits, where customers may want to learn more about the company in finer detail than what is supplied on a supplier questionnaire.”

“If you need to get in touch regarding technical special steels and alloy queries, or if you have queries regarding our quality management system, please let me know.”

Hand-picked steel manufacturers

Head of sales and purchasing, Nigel Johnson explains “With an unwavering focus on steel quality, INTOCO collaborates with a carefully chosen group of suppliers for their materials.” “Each supplier undergoes a thorough audit and fully understands our stringent requirements,” explains Tony. “Achieving quality demands hard work and a long-term commitment from both parties. Consequently, we maintain relationships with a select, stable group of suppliers who have partnered with us for many years, fostering strong, trust-based relationships.”

While INTOCO occasionally brings on new suppliers to address gaps in their product range, these suppliers must undergo a rigorous approval process. “We continually anticipate demand more than a year in advance, making stock projection crucial to meeting customer needs. Our trusted supplier network allows us to predict demand accurately and ensure an uninterrupted supply.”

No external funding

Remarkably, for such a large supplier of high-end alloys, INTOCO works entirely without any external financing. “All of our operations are funded by our extensive cash reserves, which are constantly increased to facilitate the purchasing of stock and provide services to our customers,” explains Tony. “It’s very important to us that we are fully cash-funded, and it’s fairly unique in the industry. Having large cash reserves means we can immediately purchase what we need, get it on the shelves, and ship it to the clients without delay. This has been the INTOCO policy for many years, and it applies to both the manufacturing and the distribution sides of the company.”

The INTOCO family

When talking with Tony and his close-knit team, it quickly becomes apparent that the INTOCO management team company is a no-fuss, hard-working group that quietly and consistently delivers an extraordinary level of service to demanding applications. However, one aspect of the business of which they are clearly very proud is their staff, many of whom have been with the company for decades.

“We have team members who have been with us for up to 40 years, which is truly unique and a testament to their dedication and enjoyment of this journey with us. The depth of experience and expertise within our workforce is remarkable. In today’s world, where frequent job changes are common, having employees choose to stay with us for their entire careers is quite extraordinary.”

“This loyalty is not only a result of favourable working conditions but also the supportive environment we foster. We truly are a family. It speaks volumes about a company when its employees demonstrate such unwavering loyalty.”

Manufacturing experience = technical expertise

INTOCO is, in fact, two divisions operating within the same company. One division is a speciality steel supplier, and the other is a manufacturing division focused on the aluminium extrusion press industry. The divisions operate as completely separate entities.

“Our design team, which specialises in tooling and press parts for aluminium extrusion presses, serves that application in almost every country in the world,” explains Tony. “With that business dating back to our foundation over fifty years ago, it is the basis for our extensive knowledge in machining and manufacturing” (see box ‘A history in machining & manufacturing’).

Extensive machining capabilities

In addition to providing specialist alloys in a huge variety of sizes, INTOCO also has extensive machining capabilities to add value to raw materials. The company’s vast in-house knowledge of machining, which has been gained and sharpened through its manufacturing division, has provided the capabilities and technical know-how to carry out extensive machining operations.

“Our design team has in-depth knowledge of machining and manufacturing far beyond that of regular suppliers, with our factory able to handle components weighing up to eight tonnes,” explains Tony.

“The team can machine everything from very small to extremely large items to provide some added value. These include activities as diverse as deep hole boring to heat treatment and a range of ancillary services. Our machines can provide high-quality finishes on sawn products.”

“An ongoing investment program ensures our capabilities are forever increasing to meet customer demands. Usually, we are asked to rough-machine raw materials to a certain point. However, we’re careful not to infringe on our customers’ activities. We will never compete with them by producing finished products for the oil and gas sector; our activities are limited to helping them save time and machining costs.”

A history in machining & manufacturing

INTOCO started its journey in 1972, manufacturing and pre-machining die blanks for the aluminium extrusion industry. In 1978, the company expanded into supplying hot work die steel by carrying an immense stock of W.2344 & W.2714 ranging in diameter from 150mm to 650mm. It was able to offer blanks close to their finished size with 24-hour delivery anywhere in the county. This approach was a radical change for the die industry, which had previously had to rely on rough-forged unannealed die blanks, which were massively oversized in their diameter thickness. INTOCOs bold, game-changing strategy set it up for future success, as it enabled the company to generate the capital required to expand into a very large manufacturing facility serving the metal extrusion industry.

From that point, the company branched out into supplying stainless steel and nickel alloys, which proved to be a second huge success. “When we only stocked two grades of steel, we had every diameter available, and that business model is still in place today with regard to stock levels” explains Tony. “We can deliver the sizes our customers need, on-demand, every time, without delay.”

Looking to the future

The company’s sustained success over the years has ingrained a forward-thinking approach within the INTOCO team. Upcoming developments include a significant expansion of warehouse and office facilities to accommodate increased stock levels, as well as plans to venture into more demanding applications that require high-end alloys.

Tony continues, “We have recently acquired land to construct a new large-scale facility. Our plans include expanding our product range to incorporate additional grades of alloys, which will broaden our customer base. We are also considering a full expansion into the plate and aerospace sectors. Our current pool of suppliers can already provide the necessary alloys, and our internal systems and quality control meet the high standards required to serve these exceptionally demanding industries.”

“We place a high value on the quality of our products and the integrity of our business. We welcome open conversations that can initiate long-lasting relationships based on respect, integrity, and stability. This approach has established INTOCO as a trusted supplier of specialised stainless steels and nickel alloys.”

About this Featured Story

This Featured Story appeared in Stainless Steel World July / August 2024 magazine. To read many more articles like these on an (almost) monthly basis, subscribe to our magazine (available in print and digital format) – SUBSCRIPTIONS TO OUR DIGITAL VERSION ARE NOW FREE.

Every week we share a new Featured Story with our Stainless Steel community. Join us and let’s share your Featured Story on Stainless Steel World online and in print.