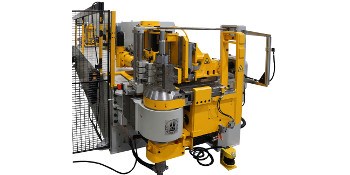

JPC, a subsidiary of UK-based UKF Group, specialises in the production of perforated components made directly from a tube in a diverse range of materials. The company has also diversified into a variety of other tube-related services, such as bending materials used in the production of auto parts. For this field of application, JPC is reliant on tube and pipe-bending machines that process large quantities while maintaining a consistently high level of precision. The new CNC 80 E TB MR supplied by Schwarze-Robitec enables the supplier to achieve these goals. Offering fast cycle times, the fully electric machine is specially designed and optimised for multi-shift operation in the automotive industry. Quick Tool Unlock, the rapid clamping system devised by the German expert for tube cold bending machines, enables the bend formers to be changed swiftly, with almost no tools required. This reduces refitting times, which in turn enables the tube bending machine to deliver higher productivity.

In a bid to achieve a high level of repeatability when grappling with challenging geometries and bending materials as well as thin wall thicknesses, Schwarze-Robitec has integrated a vertical height-adjustable pressure die into the multi-stack tube and pipe bending machine. This leads to a noticeable improvement in bending results with multilevel bending tools, as the pressure die always travels to the bending level required in each specific case.