1000 Kelvin has introduced the second generation of its AMAIZE AI co-pilot for additive manufacturing.

The updated solution is said to expand ‘far beyond’ toolpath automation to include ‘nearly the entire metal laser powder bed fusion workflow.’ In doing so, 1000 Kelvin suggests it is making the 3D printing process more reliable, efficient and scalable.

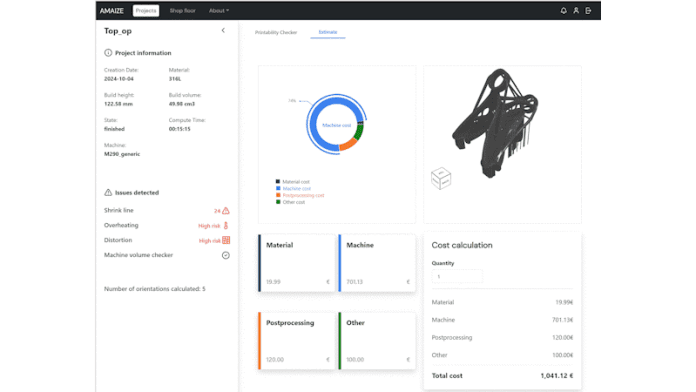

Among the platform’s new features are a printability checker that automatically validates and optimised design for AM, reducing redesign cycles by 40%, and a cost estimator, which delivers upfront cost estimations that are said to improve quoting accuracy by 30%.

AMAIZE 2.0 also incorporates physics-based build preparation to save up to 20% in material costs and enable non-experts to ‘easily implement’ successful print preparation workflows. An exposure strategy optimisation feature, meanwhile, works to ensure first-time-right prints with AI-driven parameters, cutting failure rates in half.

AMAIZE 2.0 is available for early adopters, with 1000 Kelvin already putting the new software solution in the hands of companies like EMERSON, HENNgineered, FKM, A*Star, and Ultimetal.